Jun 2 2015

Researchers from the KTH Royal Institute of Technology and Stanford University have developed a new technique for producing elastic high-capacity batteries using wood pulp. The breakdown of tree fibers results in nanocellulose, which is used to produce an elastic, foam-like battery material resistant to stress and shock.

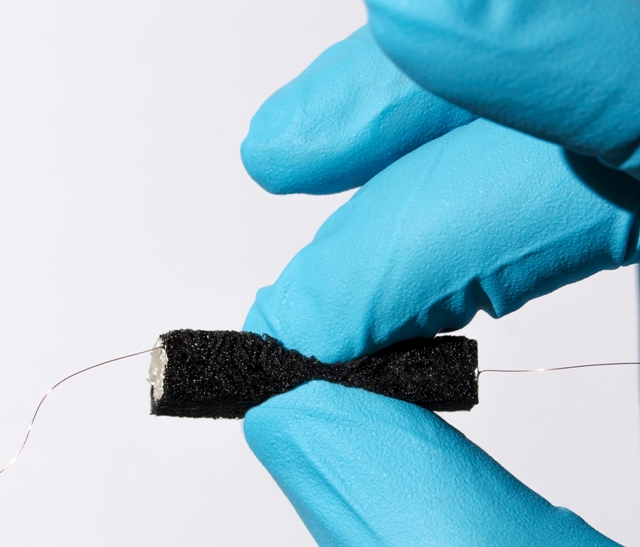

A closeup of the soft battery, created with wood pulp nanocellulose. (Credit: Max Hamedi and Wallenberg Wood Science Center)

A closeup of the soft battery, created with wood pulp nanocellulose. (Credit: Max Hamedi and Wallenberg Wood Science Center)

"It is possible to make incredible materials from trees and cellulose," said Max Hamedi, who is a researcher at KTH and Harvard University. The main advantage of the wood-based aerogel material is that it can be applied in 3D structures.

"There are limits to how thin a battery can be, but that becomes less relevant in 3D. We are no longer restricted to two dimensions. We can build in three dimensions, enabling us to fit more electronics in a smaller space," Hamedi said.

He added that, unlike conventional batteries, the 3D structure is capable of storing more energy in a small space.

"Three-dimensional, porous materials have been regarded as an obstacle to building electrodes. But we have proven that this is not a problem. In fact, this type of structure and material architecture allows flexibility and freedom in the design of batteries," Hamedi said.

The method involves breaking down tree fibers and making them as many as one million times thinner. The nanocellulose is dissolved, frozen and freeze-dried such that the moisture escapes without experiencing a liquid state. Following this, the molecules in the material are stabilized to prevent material collapse.

"The result is a material that is both strong, light and soft. The material resembles foam in a mattress, though it is a little harder, lighter and more porous. You can touch it without it breaking," Hamedi said.

The final aerogel product can be processed with electronic properties. "We use a very precise technique, verging on the atomic level, which adds ink that conducts electricity within the aerogel. You can coat the entire surface within," he stated.

The material can be compared to a pair of human lungs in terms of surface area. The human lung can be spread over a wider area if unfolded. Similarly, a single cubic decimeter of aerogel material could cover a huge area.

"You can press it as much as you want. While flexible and stretchable electronics already exist, the insensitivity to shock and impact are somewhat new," Hamedi said.

The aerogel batteries could find potential applications in electric car bodies and in clothing with a lining.

The study was carried out at the Wallenberg Wood Science Center at KTH. The research is based on the previous work of KTH Professor Lars Wågberg on aerogels. As well as Lars Wågberg, Professor Yi Cui from Stanford University was also involved in the project.