Feb 25 2018

Properties of solid surfaces, such as adhesion and wetting, are crucially dependent on their fine structures. However, our knowledge of the precise manner in which the sliding behavior of liquid droplets relies on surface microstructures has been restricted.

At present, Shasha Qiao, Qunyang Li, and Xi-Qiao Feng, physicists at Tsinghua University in Beijing, China, have performed experimental as well as theoretical research on the frictional impact of liquid droplets on micro-structured surfaces. The researchers have discovered that under the same solid fraction, friction on surfaces that have a structure formed of micro-holes is considerably higher when compared to that on surfaces on which an array of pillars are formed. This has been reported in a paper published in European Physical Journal E: Soft Matter and Biological Physics.

Micro-structured surfaces such as these have assisted in designing innovative surfaces that closely resemble surfaces found in nature, for example, reduced-drag surfaces, self-cleaning surfaces, variants with anti-icing or heat transfer characteristics, surfaces with the potential to transport liquids in microfluidic systems, and also surfaces that allow oil-water separation.

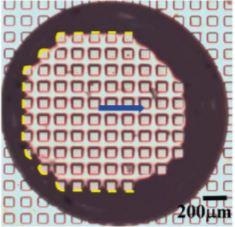

Snapshots of contact line configurations when water droplets slide on surfaces with micro-pillars. (Image credit: S. Qiao, Q. Li and X. Q. Feng (2018), Sliding friction and contact angle hysteresis of droplets on micro-hole-structured surfaces, Eur. Phys. Jour. E 41:25, DOI 10.1140/epje/i2018-11631-x)

Snapshots of contact line configurations when water droplets slide on surfaces with micro-pillars. (Image credit: S. Qiao, Q. Li and X. Q. Feng (2018), Sliding friction and contact angle hysteresis of droplets on micro-hole-structured surfaces, Eur. Phys. Jour. E 41:25, DOI 10.1140/epje/i2018-11631-x)

In this research, the focus of the researchers is on the sliding behavior of a droplet on micro-hole-structured surfaces. In the recent past, the same team demonstrated that the proportion of space occupied by solids in a unit-area surface could have a notable impact on the sliding behavior of liquid droplets on surfaces that have micro-pillar structures.

In this work, the researchers show that the continuity of the surface micro-structures could also greatly modify the sliding behavior of the droplets. They demonstrate that increase in the solid area fraction consequently increased the sliding friction. This deduction was experimentally confirmed by readily sliding a water droplet on solid surfaces that had differing sizes of micro-pillars and micro-holes while at the same time evaluating the resultant sliding friction forces.

Then, the researchers qualitatively elucidate the difference in friction between micro-pillar and micro-hole surfaces by creating an enhanced theoretical model, which advances the classic wetting mechanics model by taking into account a finite effective range of the solid-liquid-gas contact line.

Reference: Sliding friction and contact angle hysteresis of droplets on micro-hole-structured surfaces. S. Qiao, Q. Li and X. Q. Feng (2018), Eur. Phys. J. E 41: 25, DOI 10.1140/epje/i2018-11631-x