Apr 11 2018

A team of researchers from the Ruhr-Universität Bochum (RUB) and the University of Warwick could observe the minutest details of hydrogen production using pentlandite, a synthetic mineral. This enables the development of approaches for designing cost-efficient and rugged catalysts for hydrogen production.

The working teams of Professor Dr. Wolfgang Schuhmann and Dr. Ulf-Peter Apfel from the RUB and the group led by Professor Dr. Patrick R. Unwin from the University of Warwick have reported their study in the Angewandte Chemie journal on March 9, 2018.

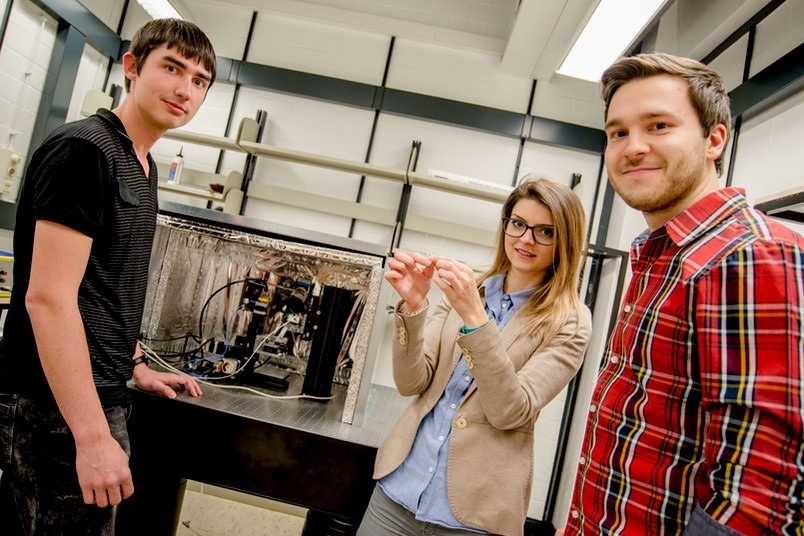

The team from Bochum in the laboratory: Tsvetan Tarnev, Corina Andronescu, and Mathias Smialkowski (from the left). (Image credit: RUB, Marquard)

The team from Bochum in the laboratory: Tsvetan Tarnev, Corina Andronescu, and Mathias Smialkowski (from the left). (Image credit: RUB, Marquard)

Hydrogen gas is regarded as a prospective future source of energy and can be synthesized from water by using electricity and platinum catalysts. Yet, there is hardly any knowledge of substitutive catalysts formulated from low-cost and more readily available materials that have equally high efficiency.

Electrodes Without Precious Metals

There are several materials which, similar to platinum, have the ability to catalyze the reaction for synthesizing hydrogen from water. “These include metal chalcogenides such as the mineral pentlandite, which is just as efficient as platinum and is also significantly more stable towards catalyst poisons such as sulphur,” explained Ulf-Peter Apfel. Pentlandite contains sulfur, nickel, and iron and has a structure similar to that of the catalytic centers of hydrogen-producing enzymes contained in different sources, such as green algae.

A Drop with a Diameter of Only a Few Hundred Nanometers

As part of their study, the scientists analyzed the hydrogen production rates of artificially formed crystalline surfaces of the pentlandite mineral in a drop of liquid that has a diameter of a few hundred nanometers. To achieve this, they used scanning electrochemical cell microscopy.

This allowed the researchers to clarify the impact of the structure and composition of the material on the electrocatalytic characteristics of iron-nickel sulfide. Even when the ratio between nickel and iron was changed very little by altering the synthesis conditions or the aging of the material, there was a considerable change in the activity in the electrochemical hydrogen formation.

“With these findings, we can now continue to work and develop strategies to improve many more robust and cheap catalysts,” stated Ulf-Peter Apfel.

Design Principles for Electrodes

The scientists also demonstrated that scanning electrochemical cell microscopy can be used to link information on the structure, composition, and electrochemical activity of the materials in a spatially resolved way. Thus, the technique enables specific designing of catalysts and the production of highly active materials.

“In future, this method will therefore play an important role in the search for electrocatalytically active, heterogeneous catalysts,” stated Wolfgang Schuhmann.