Nov 9 2018

A major cause for the slow progress of wearable biosensors for health monitoring is the absence of a lightweight, long-lasting power supply. Currently, researchers at the University of Massachusetts Amherst led by materials chemist Trisha L. Andrew state that they have formulated a technique for building a charge-storing system that can be easily incorporated into clothing for “embroidering a charge-storing pattern onto any garment.”

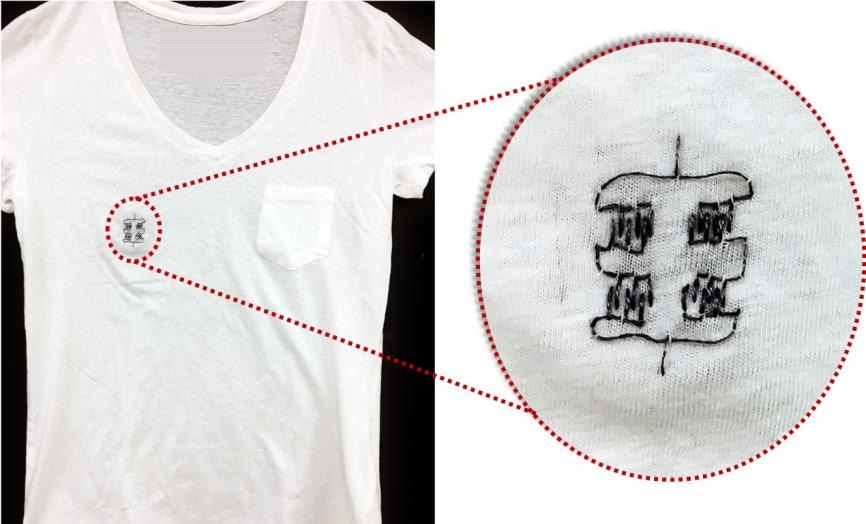

T-shirt image (Credit: University of Massachusetts Amherst)

T-shirt image (Credit: University of Massachusetts Amherst)

“Batteries or other kinds of charge storage are still the limiting components for most portable, wearable, ingestible or flexible technologies. The devices tend to be some combination of too large, too heavy and not flexible.”

Trisha L. Andrew, Materials Chemist, Wearable Electronics Lab, University of Massachusetts Amherst.

Their new technique uses a micro-supercapacitor and integrates vapor-coated conductive threads with a polymer film, as well as a special sewing method to form a flexible mesh of aligned electrodes on a textile backing. The ensuing solid-state device has a high ability to store charge for its size, and other features that permit it to power wearable biosensors.

Andrew adds that while scientists have brilliantly miniaturized a number of different electronic circuit parts, so far the same could not be said for charge-storing devices. “With this paper, we show that we can literally embroider a charge-storing pattern onto any garment using the vapor-coated threads that our lab makes. This opens the door for simply sewing circuits on self-powered smart garments.” Details of the research can be found online in ACS Applied Materials & Interfaces.

Andrew and postdoctoral researcher and first author Lushuai Zhang, plus chemical engineering graduate student Wesley Viola, emphasize that supercapacitors are perfect options for wearable charge storage circuits as they naturally have higher power densities compared to batteries.

But “incorporating electrochemically active materials with high electrical conductivities and rapid ion transport into textiles is challenging,” they add. Andrew and colleagues demonstrate that their vapor coating process forms porous conducting polymer films on thickly-twisted yarns, which can be easily swelled with electrolyte ions and maintain high charge storage capacity per unit length as compared to previous work with extruded or dyed fibers.

Andrew, who directs the Wearable Electronics Lab at UMass Amherst, observes that textile scientists are inclined not to use vapor deposition because of technical snags and high costs, but of late, research has revealed that the technology can be scaled up and remain economical.

She and her team are, at present, collaborating with others at the UMass Amherst Institute for Applied Life Sciences’ Personalized Health Monitoring Center on integrating the new embroidered charge-storage arrays with e-textile sensors and low-power microprocessors to design smart garments that can track a person’s joint movements and gait throughout a regular day.