KIC today announced plans to exhibit in Booth 1G10 at NEPCON China, scheduled to take place April 24-26, 2019 at the Shanghai World Expo Exhibition & Convention Center. Company representatives will showcase the new SRA (Smart Reflow Analyzer) and RPI i4.0.

KIC SRA in Pallet

KIC SRA in Pallet

The SRA is an integrated fixture and profiler specifically designed for collecting reflow oven related data to analyze and track machine stability from run to run, and over time. As it contains a built-in data collection module, it is an all-in-one smart fixture. This means that the SRA can be used no matter whose profiler you may currently have.

The SRA has six embedded thermocouples – three Air TCs and three Mass TCs – which are used to calculate and display a variety of data for each oven zone such as measured zone temperatures and side to side uniformity. With the use of the SRA, users also are able to identify changes in heat transfer in a zone over time, through the display of HTI (Heat Transfer Index). Additionally, it utilizes the latest in laser sensor technology to automatically measure the conveyor speed each time you run it through your machine.

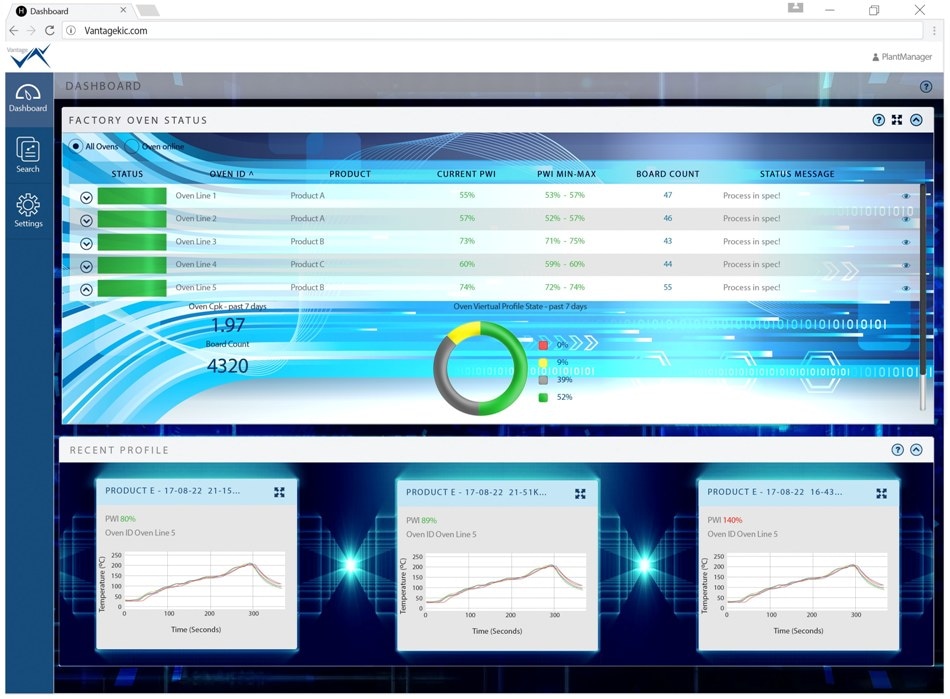

RPI i4.0 is an easy built-in solution for automation, traceability, advanced reflow data collection and sharing for Smart Factory integration. KIC RPI i4.0 automatically acquires profile data from each PCB soldered in the reflow or curing oven, in real-time. This new ecosystem offers real-time thermal process dashboard and traceability, reduced scrap and rework, fast defect troubleshooting, lower electricity use and more. Advanced data search and communication features save engineers valuable time.

KIC RPI i4.0 Vantage-Dashboard

With RPI i4.0, all relevant data can connect to the factory MES or your factory data collection system to be easily shared with personnel, and can be accessed from any authorized PC or mobile device. The enhanced level of automation delivers improved line utilization and productivity.

Move toward the future of line connectivity, flexible production, process transparency, machine learning and real-time insight.