Apr 26 2019

At DOE’s Lawrence Berkeley National Laboratory (Berkeley Lab), scientists have successfully 3D-printed an all-liquid device that can be recurrently reconfigured on demand by simply clicking a button.

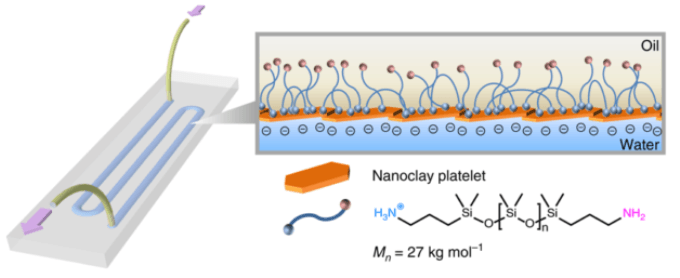

When two liquids—one containing nanoscale clay particles, another containing polymer particles—are printed onto a glass substrate, they come together at the interface of the two liquids and within milliseconds form a very thin channel or tube about 1 millimeter in diameter. (Image credit: Berkeley Lab)

When two liquids—one containing nanoscale clay particles, another containing polymer particles—are printed onto a glass substrate, they come together at the interface of the two liquids and within milliseconds form a very thin channel or tube about 1 millimeter in diameter. (Image credit: Berkeley Lab)

The all-liquid “lab on a chip” can be used in a broad range of applications, from screening drug candidates to making battery materials.

What we demonstrated is remarkable. Our 3D-printed device can be programmed to carry out multistep, complex chemical reactions on demand. What’s even more amazing is that this versatile platform can be reconfigured to efficiently and precisely combine molecules to form very specific products, such as organic battery materials.

Brett Helms, Study Lead and Staff Scientist, Materials Sciences Division and Molecular Foundry, Berkeley Lab.

Reported in the journal Nature Communications, the results of the study are the latest in a series of experiments at Berkeley Lab that create all-liquid materials using a 3D printer.

In the previous year, Helms and Thomas Russell, a visiting researcher from the University of Massachusetts at Amherst who heads the Adaptive Interfacial Assemblies Toward Structured Liquids Program in the Materials Sciences Division of Berkeley Lab, co-authored a study that led to a novel method for printing many different liquid structures, ranging from swirling threads of liquid to droplets, within another liquid.

After that successful demonstration, a bunch of us got together to brainstorm on how we could use liquid printing to fabricate a functioning device. Then it occurred to us: If we can print liquids in defined channels and flow contents through them without destroying them, then we could make useful fluidic devices for a wide range of applications, from new types of miniaturized chemical laboratories to even batteries and electronic devices.

Brett Helms, Study Lead and Staff Scientist, Materials Sciences Division and Molecular Foundry, Berkeley Lab.

Wenqian Feng, lead author and a postdoctoral researcher in Berkeley Lab’s Materials Sciences Division, developed the 3D-printable fluidic device by designing a uniquely patterned glass substrate. When two kinds of liquids—one containing polymer particles and another containing nanoscale clay particles—are printed onto the substrate, they collectively reach the interface of both the liquids and form an extremely thin tube or channel, measuring approximately 1 mm in diameter, within milliseconds.

After the formation of the channels, catalysts can then be placed in the varied channels of the device. Subsequently, users can 3D-print the bridges between channels, linking them in such a way that a chemical passing through them comes across catalysts in a particular order, triggering off a range of chemical reactions to form certain chemical compounds. When this complex process is controlled by a computer, it can be easily automated “to execute tasks associated with catalyst placement, build liquid bridges within the device, and run reaction sequences needed to make molecules,” Russell stated.

It is also possible to program the multitasking device to act like an artificial circulatory system that isolates molecules passing through the channel and automatically eliminates unnecessary byproducts while it goes on to print a series of bridges to particular catalysts, and executes the chemical synthesis steps.

The form and functions of these devices are only limited by the imagination of the researcher. Autonomous synthesis is an emerging area of interest in the chemistry and materials communities, and our technique for 3D-printing devices for all-liquid flow chemistry could help to play an important role in establishing the field.

Brett Helms, Study Lead and Staff Scientist, Materials Sciences Division and Molecular Foundry, Berkeley Lab.

The combination of materials science and chemistry expertise at Berkeley Lab, along with world-class user facilities available to researchers from all over the world, and the young talent that is drawn to the Lab is unique. We couldn’t have developed this program anywhere else.

Thomas Russell, Visiting Researcher, University of Massachusetts Amherst.

Next, the team is planning to electrify the device’s walls utilizing conductive nanoparticles to expand the kinds of reactions that can be investigated.

“With our technique, we think it should also be possible to create all-liquid circuitry, fuel cells, and even batteries,” stated Helms. “It’s been really exciting for our team to combine fluidics and flow chemistry in a way that is both user-friendly and user-programmable.”

The Molecular Foundry is a DOE Office of Science User Facility that specializes in nanoscale science. The study also involved scientists from UC Berkeley. The technology is available for collaboration and licensing. The DOE Office of Science supported the study.

Researchers from Berkeley Lab’s Materials Sciences Division and Molecular Foundry have 3D-printed an all-liquid “lab on a chip” that can serve a wide range of applications, from making battery materials to screening drug candidates. (Video credit: Helms Research Group/Berkeley Lab)