Nov 13 2019

For the first time, scientists at Linköping University, Campus Norrköping, and Research Institutes of Sweden (RISE) have demonstrated that complete integrated circuits can be printed with over 100 organic electrochemical transistors. The result of the study has been reported in Nature Communications.

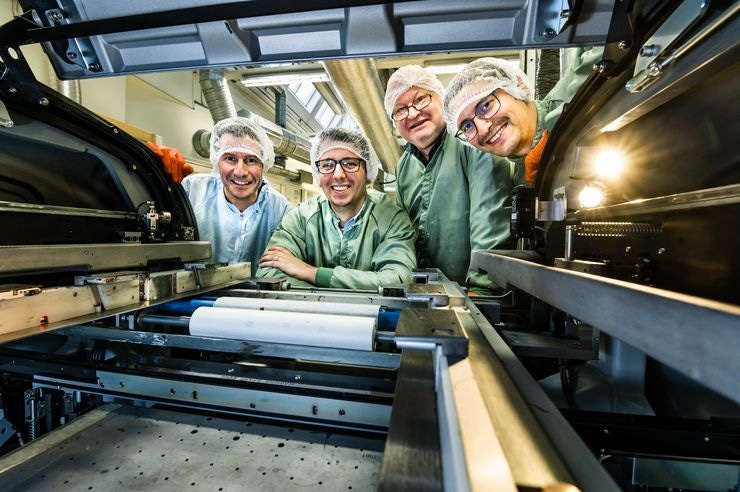

Some of the researchers behind the breakthrough: Peter Andersson Ersman, RISE; Simone Fabiano, LiU; Jan Strandberg and Roman Lassnig, RISE. Image Credit: Thor Balkhed.

Some of the researchers behind the breakthrough: Peter Andersson Ersman, RISE; Simone Fabiano, LiU; Jan Strandberg and Roman Lassnig, RISE. Image Credit: Thor Balkhed.

This is a decisive step for a technology that was born at Linköping University just over 17 years ago. The result shows that we are again leading the field, thanks to the close collaboration between basic research at the Laboratory of Organic Electronics, LOE, and applied research at RISE.

Magnus Berggren, Professor and Director, Laboratory of Organic Electronics, Linköping University

“The advantage we have here is that we do not need to mix different manufacturing methods: everything is done by screen printing, and in relatively few processing steps. The key is ensuring that the different layers end up in exactly the right place,” stated Peter Andersson Ersman, a researcher in printed electronics at the RISE.

The printing of electronic circuits featuring a line width of about 100 µm is also known to place high demands on the print technology, and research on printed electronics has been supported by the graphics industry. This industry has created screen printing frames with meshes that are capable of printing very fine lines. Developing printing ink with the right characteristics requires many hours of research.

Many Different Fundings

“The research has received funding from many different sources during the past 17 years,” informed Magnus Berggren.

These comprise Knut and Alice Wallenberg Foundation, Vinnova, and the Swedish Foundation for Strategic Research. In the recent past, the EU also became involved via the Eureka Eurostars Prolog project.

“The first breakthrough for printed circuits using screen printing came in the Prolog project. We published these results in 2017,” stated Peter Andersson Ersman.

Since that time, at least three more challenges have been tackled—that is, decreasing the size of the circuit, boosting the quality in such a way that all transistors within the circuit work lie as close to 100% as possible, and finally solving the integration issue with silicon-based circuits required to process signals as well as interact with the surroundings.

One of the major advances is that we have been able to use printed circuits to create an interface with traditional silicon-based electronic components. We have developed several types of printed circuits based on organic electrochemical transistors.

Magnus Berggren, Director and Professor, Laboratory of Organic Electronics, Linköping University

Berggren continued, “One of these is a shift-register, which can form an interface and deal with the contact between the silicon-based circuit and other electronic components such as sensors and displays. This means that we can now use a silicon chip with fewer contacts, which needs a smaller area and is in this way cheaper.”

1000 Organic Transistors on an A4

The improvements in the screen printing frames and the development of ink to print thin lines have not only played a major role in the miniaturization process but also helped in achieving better quality.

We can now place more than 1000 organic electrochemical transistors on an A4-sized plastic substrate, and can connect them in different ways to create different types of printed integrated circuits.

Simone Fabiano, Research Head, Organic Nanoelectronics, Laboratory of Organic Electronics, Linköping University

Such large-scale integrated circuits, or LSI for short, can be used, for instance, to power an electrochromic display—which itself is produced as printed electronics—or another section of the online electronic world brought by the internet of things.

The scientists used polymer PEDOT:PSS, which is the most intensely researched material in the world in the area of organic electronics.

“This material was commercially available 17 years ago, and it was pure luck that we chose to work with this particular material. We now use the same material in the integrated circuit as in the display, which makes it possible to print more efficiently. We have developed a complete process for printing circuits here at the Printed Electronics Arena in Norrköping,” stated Magnus Berggren.