.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 31 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 31 2022In an article recently published in the journal Materials, researchers reviewed recent literature on the use of cellulose in air-filtering systems concentrating on the elimination of air pollutants and gas permeability. The review covered particulate filtration (PM10, PM2.5, and PM0.3) as well as gas and water permeation in cellulose-based solutions ranging from aerogels and foams to membranes, films, and composites.

Study: Cellulose for the Production of Air-Filtering Systems: A Critical Review. Image Credit: Vink Fan/Shutterstock.com

Background

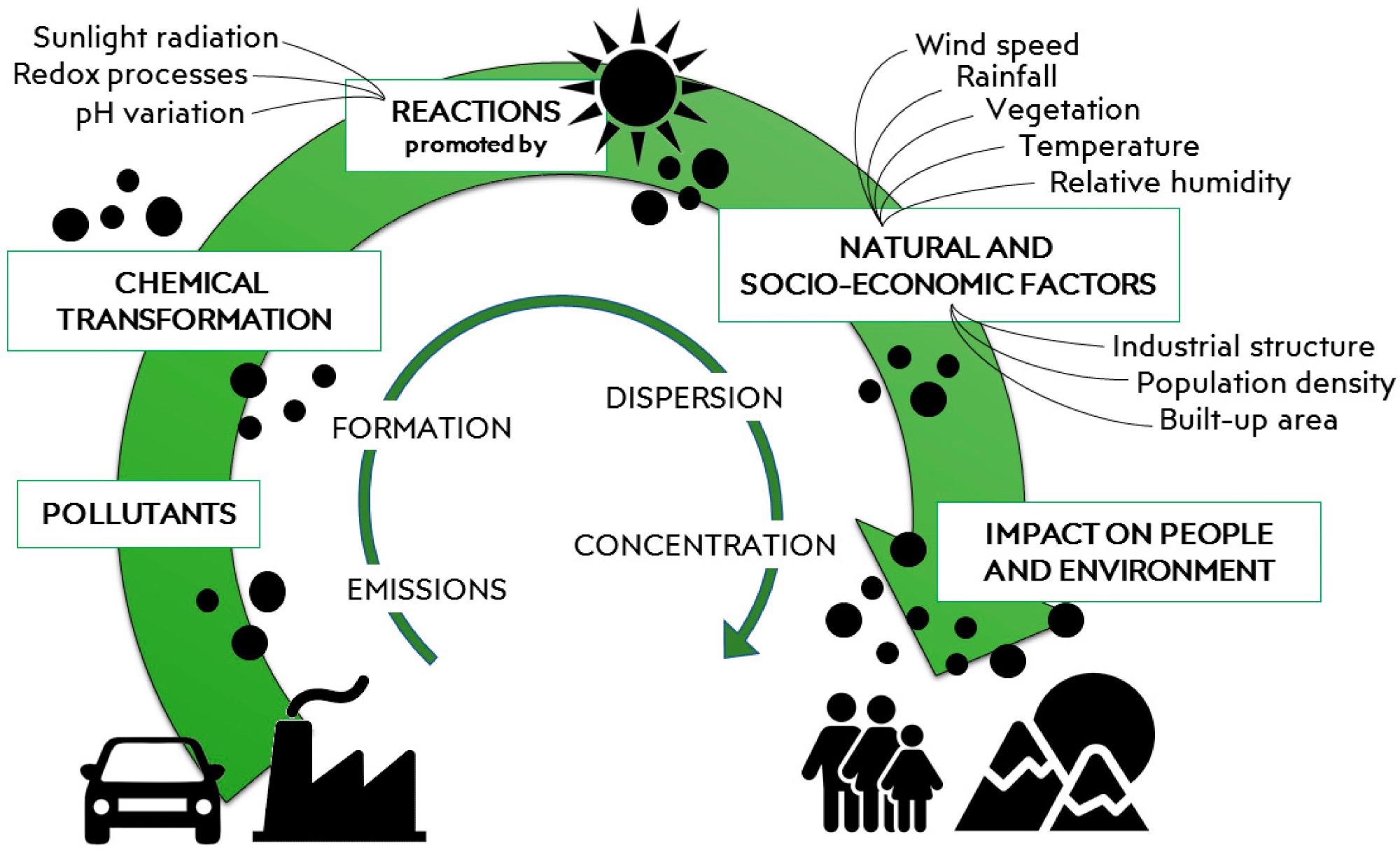

Rapid industrial growth has caused a global increase in air pollution. Natural, chemical, and socioeconomic variables all influence the dispersion of pollutants in the air and soil. The search for methods to minimize air pollution has been ongoing for a long time, owing to the significant health risks involved. Aerosol particles from air pollution are often made up of minute solid or liquid components that are categorized as particulate matter under 10 microns (PM10) or 2.5 microns (PM2.5).

Cycle of pollution from the emission to the impact on people and environment. Image Credit: Lippi, M et al., Materials

Filter membrane materials for such particle sizes have been studied extensively; however, filtering methods for particles less than 0.3 m are still being developed. Because of growing environmental awareness, the primary focus now is to create systems that can handle problems like pollution by designing green products and sustainable processes.

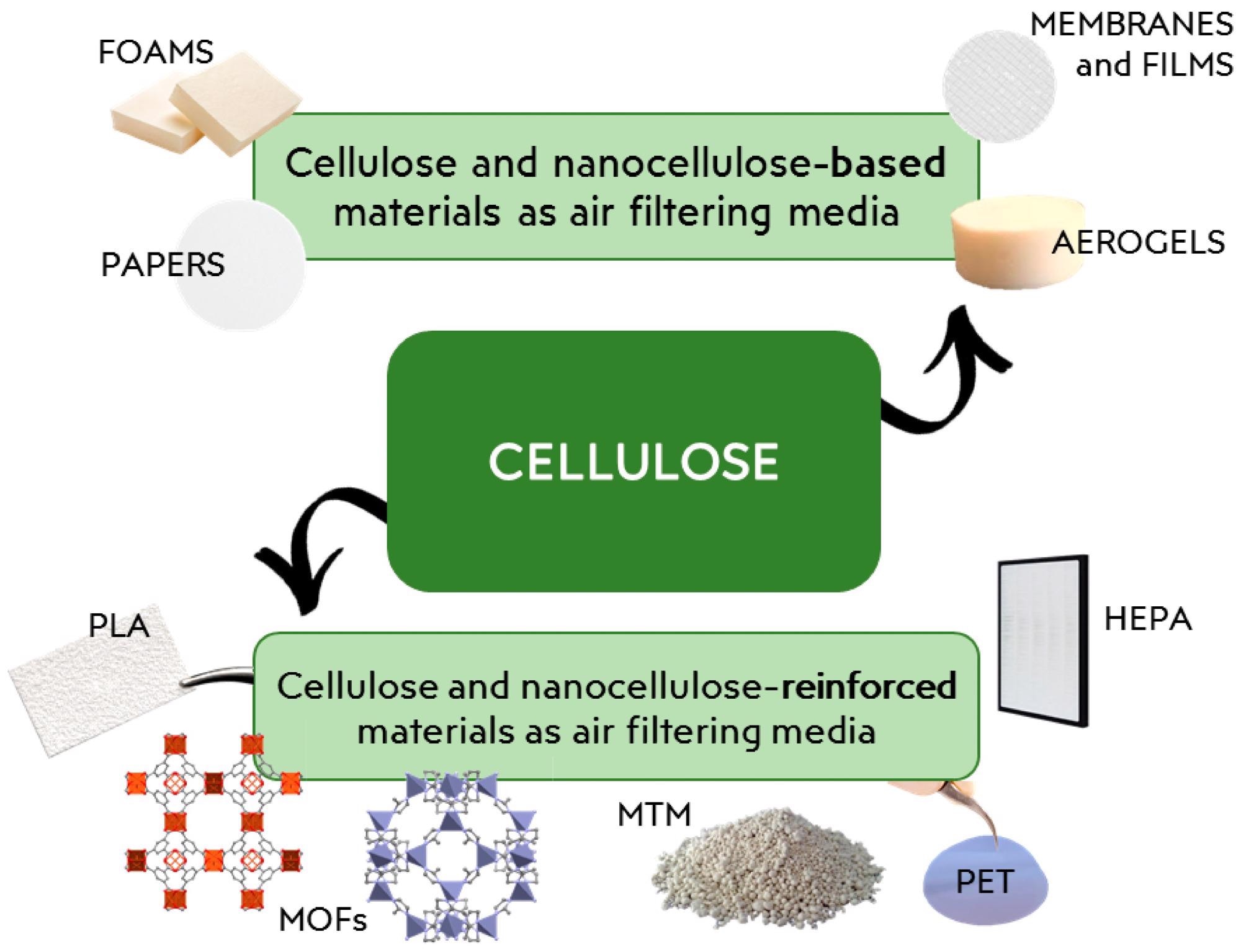

For manufacturing novel eco-friendly filtering systems, bio-based fiber materials with superior mechanical strength and gas permeability are desirable. As the most prevalent polysaccharide found in nature, cellulose has a wide range of physical and chemical properties. The renewable nature of cellulose, as well as its biodegradability, morphological properties, and chemical adaptability, make it a suitable matrix for the development of composites with a broad range of applications.

About the Study

In the present study, the researchers assessed various cellulose-based solutions in published literature based on their quality factor (QF). A high QF value (at least 0.01 Pa-1 in commercial high-efficiency particulate air (HEPA) filters) ensures the optimal compromise between high filtering efficiency (>99%) and low-pressure drop (1 kPa/g). Following a brief overview of the fundamental filtration attributes, numerous cellulose-reinforced and cellulose-based systems with ultrafiltration properties were objectively evaluated, concentrating on the differences in mechanical and chemical barrier mechanisms. The structural elements that control all the factors that define the quality of efficient gas and particulate filtering systems were given special consideration.

A range of morphological factors was explored that can enhance final filtration performance, emphasizing the necessity of employing nanofibers not only to increase surface area and adjust porosity in final solutions but also to reinforce filters composed of various materials.

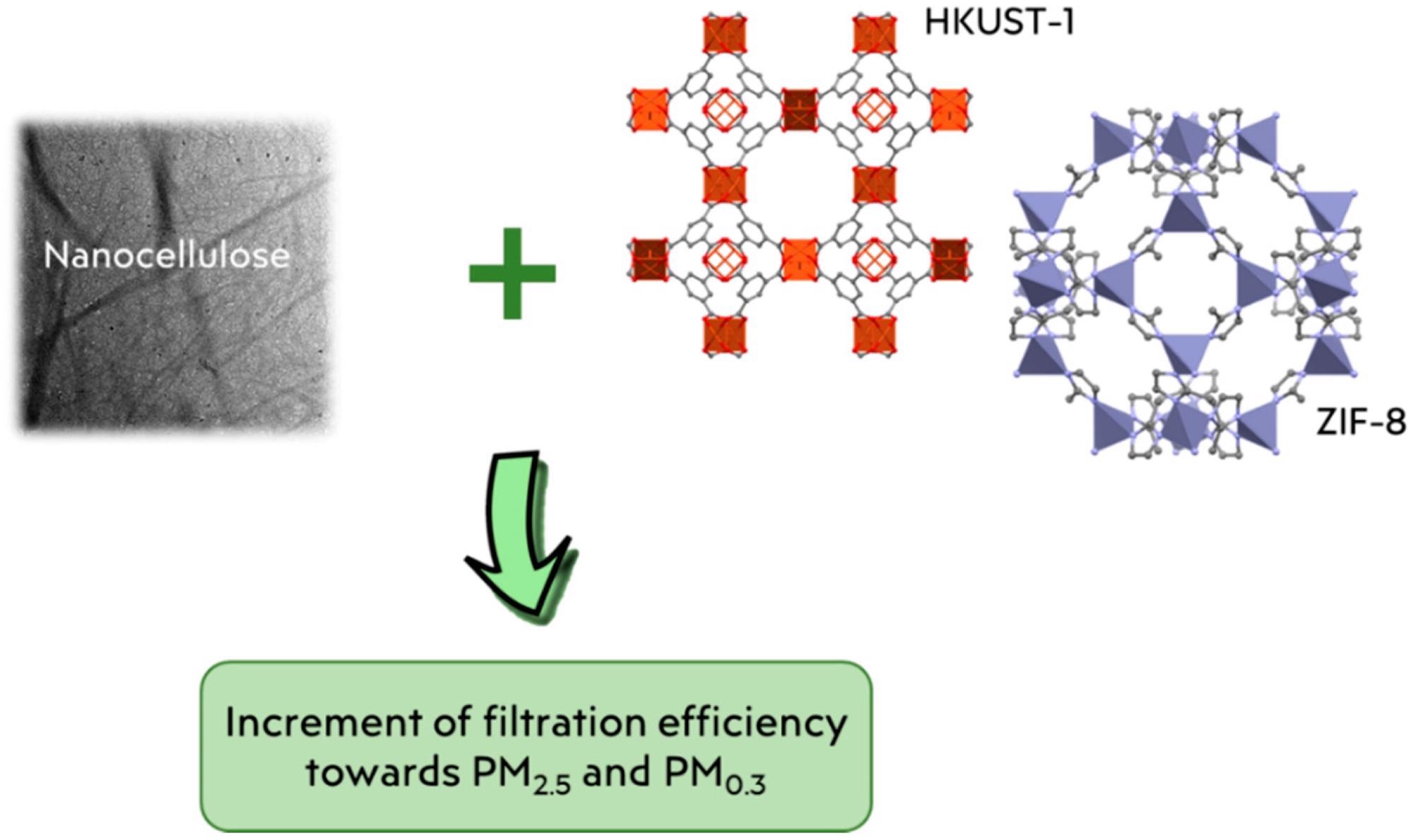

Apart from describing technological approaches to enhance mechanical filtration, selected examples of works were used to demonstrate the importance of chemical interaction facilitated by the introduction of active functional groups on the backbone of cellulose (nano)fibers in improving filtration efficiency without decreasing filter porosity.

Different filtering systems obtainable from cellulose. Image Credit: Lippi, M et al., Materials

Observations

In this review, the researchers observed that controlling the chemical and physical properties of cellulose fibers is vital to building efficient air filters having nanosized fibers that show considerable improvement in certain scenarios. In this regard, nanocellulose electrospinning opens the door to a broader range of hierarchical solutions that can improve filtration performance. Emerging technology, i.e., 3D printing of (eco)safe filters, may push morphological design toward efficient filtering in the future.

Furthermore, many studies show that the use of cellulose as a matrix or reinforce component in composites should be considered in most circumstances as the best way to attain good gas-filtration characteristics. A detailed review of some work also showed that the adsorption behavior of cellulose-based materials depends on the mechanical and diffusive processes mediated by changes in a system's morphological and physical characteristics. However, the chemical modification of the basic structure can be optimal to promote selective filtration efficiency against specific pollutants.

In one of the studies reviewed, it was observed that the addition of t-butyl alcohol (TBA) in TEMPO-oxidized cellulose nanofibers (TOCNF)/water dispersion does not affect the pressure drop value of ultra-low penetration air (ULPA) and HEPA filters. However, it increases their filtration efficiency from 0.0256 to 0.0357 for an average particle size of 0.125 and from 0.0273 to 0.0383 for particle size of 0.175 μm. This can be attributed to the TOCNF-aerogel’s morphological features.

Additionally, when considering whether microporous open structures are needed in the filtration of micro-sized volatile particles, the use of TBA as the solvent media in processing aerogel systems can serve as a good example to keep in mind, as it provides a suitable balance between the need to be efficient in removing contaminants and the need to avoid an undesired increase in pressure drop.

Representation of combined systems in which filtration efficiency is enhanced by the combination of the properties of nanocellulose and MOFs. Image Credit: Lippi, M et al., Materials

Conclusions

In conclusion, this review elucidates how cellulose may be used to process filtering materials, emphasizing both the possibilities and the advantages of doing so. An individual selection of cellulose and nanocellulose-based materials described as potential volatile-molecule filters were investigated in order to highlight progress in the adoption of these sustainable and environmentally friendly materials for applications in a variety of critical sectors, including food packaging and environmental decontamination.

Overall, the authors hope that this review may serve as a beginning point and a guide for all those interested in researching effective, environmentally beneficial, and long-lasting cellulose-based air filters.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Sources:

Lippi, M., Riva, L., Caruso, M. et al. Cellulose for the Production of Air-Filtering Systems: A Critical Review. Materials 15(3), 976 (2022).

https://www.mdpi.com/1996-1944/15/3/976