Aromatic polyimides have increasingly become the focus of research in electronics due to their favorable properties for manufacturing a variety of materials which are crucial for next-generation devices. Writing in the journal Polymers, a team of researchers from China has investigated recent progress in research in this area.

Study: Progress in Aromatic Polyimide Films for Electronic Applications. Image Credit: KPixMining/Shutterstock.com

What are Aromatic Polyimides?

Aromatic polyimides are a class of heteroaromatic polymers. These materials possess properties such as superior mechanical strength, toughness, thermal stability, excellent electrical insulation, high wear resistance, and resistance to radiation.

Many materials have been manufactured which incorporate aromatic polyimides, including carbon fiber composites, films, foams, membranes, plastics for engineering purposes, varnishes, and coatings. They have been researched thoroughly for applications in high-tech domains such as optoelectronics, the aerospace industry, and microelectronics. Aromatic polyimide materials possess variable processability and superior combination characteristics.

The first synthesis of these materials was reported in 1908, but it was not until the late 1960s that the first commercial material based on aromatic polyimides was developed by Dupont. This was due to the discovery of an efficient synthetic pathway for the manufacture of high-molecular-weight polyamides.

Currently, the most popular production processes of these important heteroaromatic polymers are poorly understood. This is due to the impact on the polymerization reaction during synthesis of conditions such as solvent, temperature, moisture, and impurities. Moreover, the addition mode of monomers can affect the molecular weight of the final material.

The Study

In the research, the authors have presented a review of recent progress in research into aromatic polyimide-based materials and their applications in the electronics sector. The team has investigated the preparation, properties, and structure of advanced aromatic polyimide films. Sixty-seven studies in the current literature were selected for review by the research team, with an exploration of research from their own laboratory alongside relevant findings from other research teams and institutions.

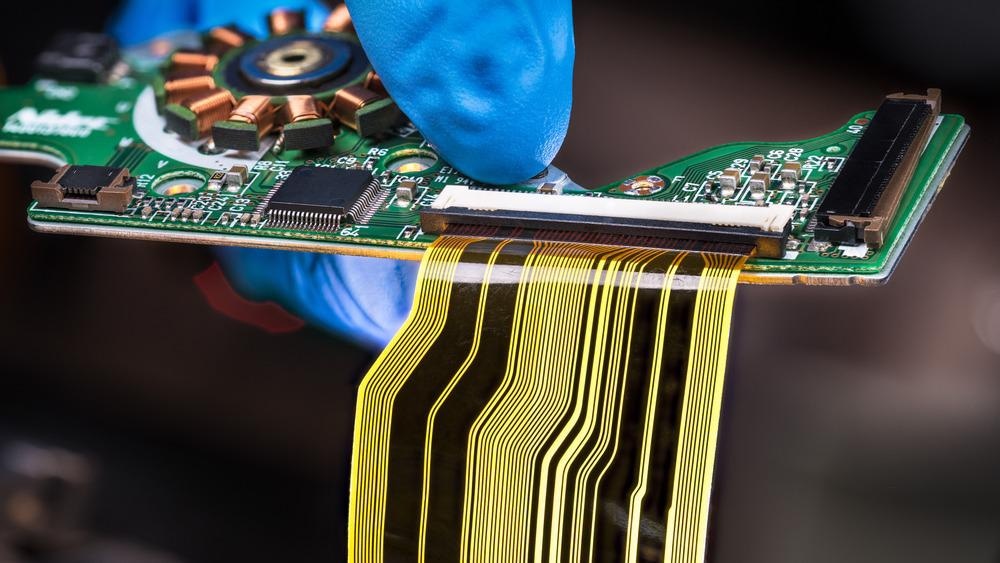

In the review, the authors have noted that several applications for advanced aromatic polyimide films have been explored in depth in the current literature. Research has led to these films being adopted for real-life applications in the microelectronics and packaging industries. Commercial uses of these materials include base films for flexible printed circuits and as substrates for flexible packaging.

More from AZoM: Microchannel Plate Detectors in Electron Spectrometers

There has been rapid progress in research concerning the line thinning of electrical circuits. This is due to improvements in miniaturization and development of thinner films in electronic and electrical parts. However, dimensional changes during service life can cause short-circuiting and disconnections, leading to safety concerns. For this reason, aromatic polyimide films must not absorb excess amounts of liquid and possess high dimensional stability and a high elastic modulus to be considered for microelectronic applications.

Several strategies have been proposed in the current literature for improving the properties of low coefficient of thermal expansion films. Chemical imidization, for instance, has been investigated for its potential to synthesize aromatic polyimide films with improved mechanical properties.

One contributing factor to the enhanced toughness of these films is the enhanced stability of imide rings which are generated during the solvent evaporation phase of processing. Fully chemically-imidized films possess superior in-plane orientation and close packing. The authors have also highlighted research into introducing ester-linked bonds and fluorinated group loadings, which has demonstrated favorable improvements to the properties of low coefficient thermal expansion films.

The team has highlighted current research into colorless films for use in flexible displays. One limitation of these films is their color, which ranges from yellow to brown. Currently, there is a high demand for films with superior heat resistance due to recent rapid progress in the field of optoelectronics. A major drawback, however, is the need to finely balance the material’s thermal properties, mechanical strength, and optical transparency. Several strategies have been developed in recent years, which have been explored in depth in the review.

Inorganic hybrid polyimide films have been highlighted in the review. An interesting research direction in recent decades has been the use of these materials in space exploration to withstand the harsh environments of outer space, with their use in multiple components such as solar arrays, thermal blankets, and inflatable components. Research into self-healing materials that can withstand the rigors of space has been carried out in recent years, with polyimide films and advanced coatings showing great potential.

Future Research Directions

The review has investigated future research directions for this exciting class of multi-functional materials to meet the demands of optoelectronics and microelectronics. Future prospects include precise control of physical changes and chemical reactions during film formation, surface modification of films including plasma treatments, improvements in the design of copolyimide film molecular structure, and imbuing polyimide films with unique properties using an inorganic-organic hybrid method.

Further Reading

Wu, Z et al. (2022) Progress in Aromatic Polyimide Films for Electronic Applications [online] Polymers 14(6) 1269 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/6/1269

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.