However, owing to their limitations, their extensive uses and commercialization have been restricted. Polyether-ether-ketone (PEEK) is a substance with inherent shape memory properties being researched all over the world.

An Introduction to Shape-Memory Materials

Shape memory materials, in principle, can 'remember' their shape and revert to that morphology when a stimulus, such as heat or light, is applied. These materials retain a "memory" of their original form.

This capacity is known as the shape memory effect (SME), and it may occur in shape memory alloys (SMAs) and polymers (SMPs), but it is also feasible in shape memory hybrids (SMHs).

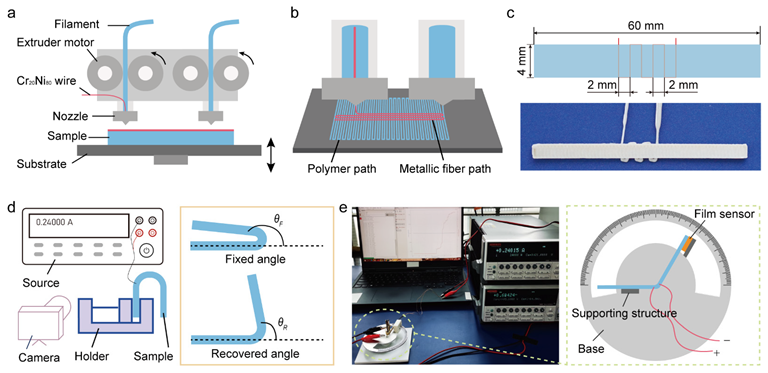

Four-dimensional printing and test method of shape memory PEEK. (a) The equipment and construction of 4D printing. (b) The process of 4D printing PEEK composites. (c) The printed composite sample and sizes. (d) The measurement method and definition of angle. θF was the fixed angle and θR was the recovered angle between the horizontal line and the free side of the sample. (e) The test method and devices of the recovery force. Image Credit: Zhou Y. et. al., Polymers

Difference Between SMPs and SMAs

An essential difference is the recovery rate. SMPs are anticipated to have a slower recovery rate than shape memory alloys (SMAs). However, the controlled strain of SMAs is only 8%, far lower than that of SMPs (up to 800%), and SMA bending capability can only be raised by constrained structural modification and design.

Applications of SMPs

Shape memory polymers have an almost endless number of possible uses. Smart textiles, automated solar panels in spaceships, autonomous medical equipment, and self-disassembling cellular phones are just a few of the fascinating prospects. Additionally, their usage for the manufacturing of intelligent garments, especially “breathable” garments with the ability to regulate human body temperature, has been quite popular.

Limitations

SMPs are used for various purposes such as occlusion gadgets for cardiac illness, autonomous fingers for grabbing movement, and digital logic circuits for configurable pneumatic computation. However, several problems are being faced due to their low glass transition temperature (Tg).

The glass transition temperature is the temperature value or range at which a hard/glassy polymeric material turns into a leathery/soft state. The low inherent transition temperature value restricts SMP usage in hostile environments limiting their applicability in the aerospace sector.

Importance of Polyether-ether-ketone (PEEK)

PEEK is a translucent natural thermoplastic polymer group that is employed in industrial engineering applications due to its exceptional tensile characteristics and shape memory. It has a greater Tg value of 143 C, which allows it to operate in lower earth orbit and be suitable for aerospace components. Furthermore, PEEK's particular high-temperature resilience and radiation resistance provide it with a wider range of applications.

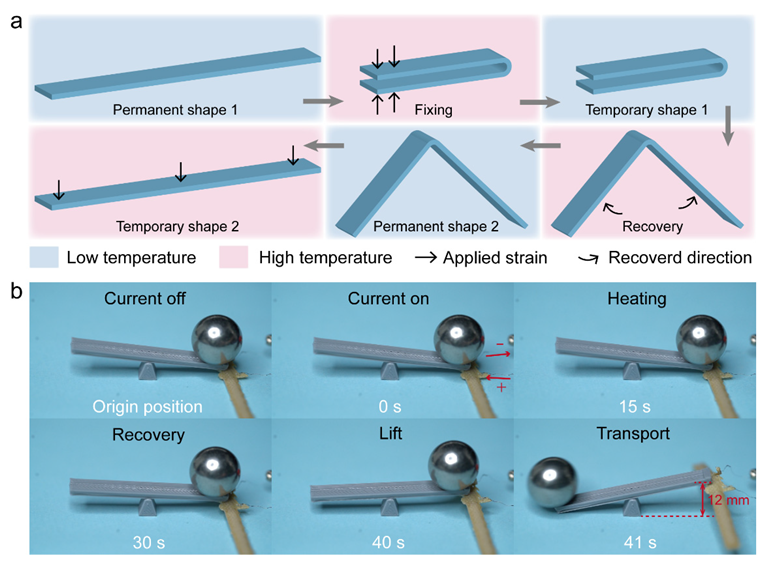

Weight transport by shape memory PEEK. (a) The programming of actuated PEEK sample. (b) The experiment process of weight transport. Image Credit: Zhou Y. et. al., Polymers

Introduction to 4-D Printing

When a 3D printed component is subjected to external input, it evolves in morphology, feature, and functioning over time. 4D printing is the process of creating items that change their shape when extracted from a 3D printer.

With exposure to water, heat, and air, these items self-assemble. 4D printing is a hybrid of 3d printing technology, smart materials, and well-programmed designs. Four-dimensional manufacturing resulted in a variety of developed architectures for SMPs to acquire more functionality by being stimulus sensitive.

Latest Research Overview

The latest study involved the investigation of shape memory characteristics and activation capabilities of high-temperature PEEK in bending movement. PEEK composites integrated with a source of excitation were manufactured using 4D printing. It was followed by an examination of shape memory behavior and actuation capability under multiple programming settings (retrieval temperatures, cooling rates) and structural variations (bending arc length, etc.).

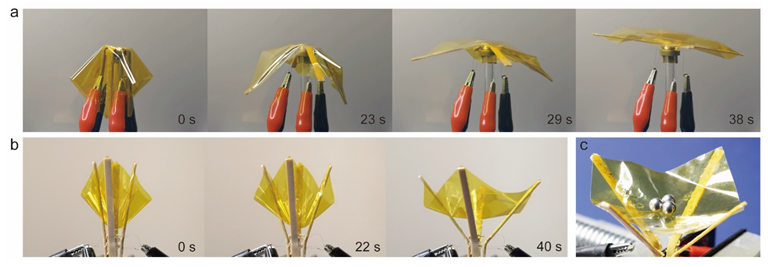

The deployable structure of shape memory PEEK. (a) An experimental simulation of deployed drag sail. (b) A mimetic catcher with deployed joints. Image Credit: Zhou Y. et. al., Polymers

Research Findings

The shape memory effect of PEEK was investigated during full-bending deformation (180) at an actuation current of 0.24 A. After 15 seconds of powering on, the temperature hit 170 degrees celsius, and noticeable restoration ensued. The maximum recovery angle occurred within the first 10s, accompanied by a slow reduction. After 70 seconds, the recovery was considered to be a steady relaxation at high temperatures.

The actuation currents and exterior temperature of the PEEK specimens displayed a strict linear connection in terms of shape memory. The sample grew softer as the current increased. When it came to cooling, forced air cooling had a better retrieval ratio (58%) than natural cooling (49%). The recuperation speed was raised by 1.5 times when forced air cooling was used.

The researchers discovered that the recovered angle was larger in specimens with a greater arc length. The recovery ratio of items with an arc length of 26 mm was 77%, whereas samples with an arc length of 10 mm only had a 49% recovery ratio.

In short, for particular circumstances, the lightweight construction of PEEK demonstrated a breakthrough. This research sets the road for potential electro-active PEEK actuator design and optimization.

Further Reading

Zhou Y. et. al. (2022). The Shape Memory Properties and Actuation Performances of 4D Printing Poly (Ether-Ether-Ketone). Polymers. 14. 3800. Available at: https://www.mdpi.com/2073-4360/14/18/3800

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.