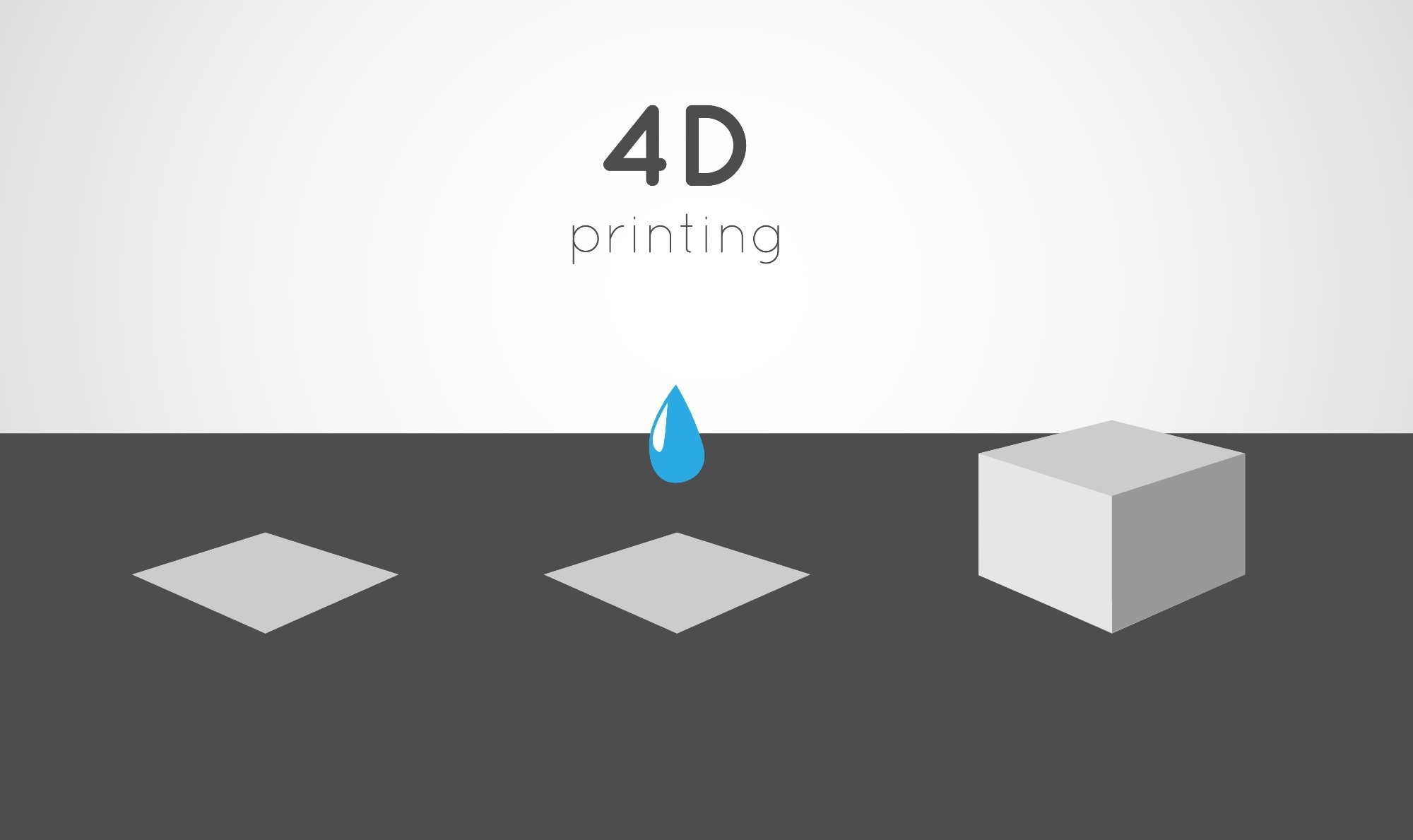

Four-dimensional (4D) printing is an additive manufacturing (AM) process in which three-dimensional (3D) printing is combined with smart materials that have shape memory. During 4D printing, the smart material responds to external stimuli in the form of a change in material property or shape.

Image Credit: nortivision/Shutterstock.com

With 4D printing, the objects can change shape or properties using external stimuli such as temperature, light, pH, magnetic field, electricity, and moisture. Additionally, the changes in shape or properties can also be pre-designed and well-controlled using the variable rate of stimulus.

Polymeric materials are particularly well suited for 4D printing due to their molecular nature, properties, and printability. The majority of polymeric materials used in 4D printing are smart materials that respond to stimuli, and they react to external stimuli due to shape memory and piezoelectric properties present at the molecular level. 4D printing is also possible with conventional materials that do not respond to external stimuli by using smart materials or making changes during the design process.

The main application of 4D printing is in the aerospace, healthcare, fashion, and lifestyle sectors. In aerospace and automobiles, smart materials that respond to changes such as temperature and light and improve performance can be developed. Improved and customized medicines can be developed in the healthcare sector with biocompatible 4D materials. In the fashion and lifestyle sector, 4D printing can be used to develop products such as self-assembling shoes and clothes.

4D Printing Methods

Fused deposition modeling (FDM) is an extrusion-based AM technique in which the filament is fed to the nozzle by a roller which is controlled by an electrical motor. A variety of polymers and composite materials can be 4D printed using the FDM method. Polylactic acid (PLA) and polyurethane (PU) are the two most used materials for 4D printing using FDM. PLA and PU are semi-crystalline thermoplastic shape memory polymers that respond to temperature changes for 4D printing.

Direct ink writing (DIW) is an additional extrusion-based AM method in which ink extrusion takes place through a syringe. During DIW, the viscoelastic ink is extruded through a nozzle under pressure, and a computer-controlled dispenser is used to construct geometries; for 4D printing using DIW, ultra-violet cross-linkable PLA is used, which acts as a shape memory material for various industrial applications.

Light-based printing methods, particularly stereolithography (SLA) and digital light processing (DLP) are also used for 4D printing of various materials. SLA can be used to develop a minimum feature size of 50 μm for 4D printing. DLP is applied to print photopolymers for 4D printing that respond to UV light. The main application of SLA and DLP printing is in the area of 4D printing of soft materials.

Selective laser sintering (SLS) is a powder-based technology, which uses a laser beam to increase the temperature of powders and converts them into a semi-liquid state to develop the finished part. 4D printing with SLS is only possible with the limited number of polymer powders that mainly include thermoplastic polyurethane (TPU), polydimethylsiloxane (PDMS), and polyamide (PA). It must be noted that to develop products for 4D printing using SLS, post-processing is an essential step.

Recent Studies

In a recent study published in the journal Trends in Food and Technology, researchers discussed the application of 4D printing in the food sector. The study indicated that 4D food printing could provide a solution to a wide range of problems in the food industry, but the extrusion process and software related to food printing need significant improvement.

In another study published in the journal Advanced Drug Delivery Reviews, researchers reviewed the scope of the 4D printing pharmaceutical sector. The main advantage of using 4D printing in the medical industry is that the customization of medicines is possible, but the fundamental limitation is that the area needs significant research and development for industrial applications.

Conclusions

4D printing is a new way to fabricate functional devices and complex structures by combining AM with smart materials. The main advantage of 4D printing is that new properties are developed in materials that are not possible using traditional manufacturing methods.

Additionally, new processing strategies and materials in 4D printing are constantly developing. The main limitation of the technology is that it is in the early stage of research, and factors such as a lack of smart materials and printing devices limit the industrial use of the technology.

More from AZoM: How is 3D Printing Used in the Field of Archeology?

References and Further Reading

Peng Fu, Haimei Li, Jin Gong, Zengjie Fan, Andrew T. Smith, Kuangyu Shen, Tebyan O. Khalfalla, Haofei Huang, Xin Qian, Jeffrey R. McCutcheon, Luyi Sun, 4D printing of polymers: Techniques, materials, and prospects, Progress in Polymer Science, Volume 126, 2022,101506, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2022.101506.

Xiuxiu Teng, Min Zhang, Arun S. Mujumdar, 4D printing: Recent advances and proposals in the food sector, Trends in Food Science & Technology, Volume 110, 2021, Pages 349-363, ISSN 0924-2244, https://doi.org/10.1016/j.tifs.2021.01.076.

Alice Melocchi, Marco Uboldi, Matteo Cerea, Anastasia Foppoli, Alessandra Maroni, Saliha Moutaharrik, Luca Palugan, Lucia Zema, Andrea Gazzaniga, Shape memory materials and 4D printing in pharmaceutics, Advanced Drug Delivery Reviews, Volume 173, 2021, Pages 216-237, ISSN 0169-409X, https://doi.org/10.1016/j.addr.2021.03.013.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.