Accurate and rapid measurement of oil and water content in oilseeds is essential for breeders, growers, and buyers to determine the market value of crops such as rapeseed (also known as canola), sunflower, linseed (also known as flax), soybeans, and groundnuts.

Image Credit: Frontpage/Shutterstock.com

Nuclear Magnetic Resonance (NMR) provides a clean, fast, and precise alternative to conventional wet chemical methods.

Additionally, maintaining NMR calibrations is considerably easier compared to Near-Infrared (NIR) spectroscopy. The method can be used to measure oil yield during the development of improved crop varieties and by seed crushers to determine the oil content of press cake and residues (ISO 10632) , facilitating calculation of extraction efficiency.

Summary

- Quick, precise, and repeatable

- Minimal sample preparation

- Simple linear calibration, no chemometrics

- The most straightforward and dependable method available: suitable for non-technical personnel.

Advantages of NMR

Solvent extraction methods are often employed to determine oil content. However, these techniques are time-intensive, require experienced operators, and involve the use of hazardous solvents.

Although NIR is a rapid technique, it only measures the surface layer, so sample grinding is often necessary to improve reproducibility.

Furthermore, NIR requires calibration using numerous reference samples representing a wide range of variables such as oil and water content, seed or grain type, and particle size or color. Consequently, results can be unintentionally inaccurate if the sample lies outside the calibration range or scope.

In contrast:

- NMR eliminates the use of hazardous solvents during analysis and disposal

- NMR, as a bulk measurement technique, can quantify all oil within the sample, regardless of particle size

- NMR is the preferred method for sunflower seeds, as it is unaffected by color; as such, it is an official USDA GIPSA method

- Oil and water calibrations can be obtained using as few as three samples

- NMR enables rapid measurement across a wide range of sample sizes

- NMR is used in the ISO 10565 method, adopted by FOSFA (Federation of Oils, Seeds and Fats Associations).

The MQC+ benchtop Nuclear Magnetic Resonance (NMR) analyzer provides an alternative to wet chemistry and NIR methods. It is fast, straightforward, easy to calibrate, and requires minimal sample preparation. This makes it ideal for routine operation, eliminating the need for additional chemicals, complex calibrations, or specialized operator training.

Image Credit: Marcin Balcerzak /Shutterstock.com

Method

Oil and water measurements involve differentiating between the two analytes based on their NMR relaxation times. The NMR signal from solids within the sample decays quickly, leaving signals originating only from oil and bound water.

Afterwards, the bound water signal decays, leaving only the oil signal. The water is calculated as the difference between the oil signal and the combined oil and bound water signals.

The ISO 10565 method recommends maintaining the water content below 10 % for all seed types to ensure valid results. In practice, this value may be several percent higher, depending on seed variety.

Calibration

As NMR is a comparative method, calibration standards consisting of actual seeds with known oil and water contents must be obtained before measurements can be made.

Although only three well-characterized seed standards are required, using at least six is recommended, with oil and water contents spanning the concentrations of interest. Reference values for oil and water are typically calculated using Soxhlet extraction for oil and oven drying for water, respectively.

Calibration quality depends on the accuracy of this reference data. However, since NMR is more reproducible than wet chemical methods, analyzing additional reference samples reduces the likelihood of errors. Alternatively, a primary calibration for total oil content can be created by NMR using the pure oil under analysis.

Measurement

Samples are poured into glass NMR tubes up to a predefined mark and weighed. Large samples are usually conditioned at ambient temperature under stable environmental conditions. Measurement time is typically 16 seconds per sample, as specified by the ISO standard procedures.

Results

Optimal accuracy is typically obtained when the standards and measurement samples belong to the same species. However, seed varieties containing oils with similar hydrogen densities may lie on the same calibration.

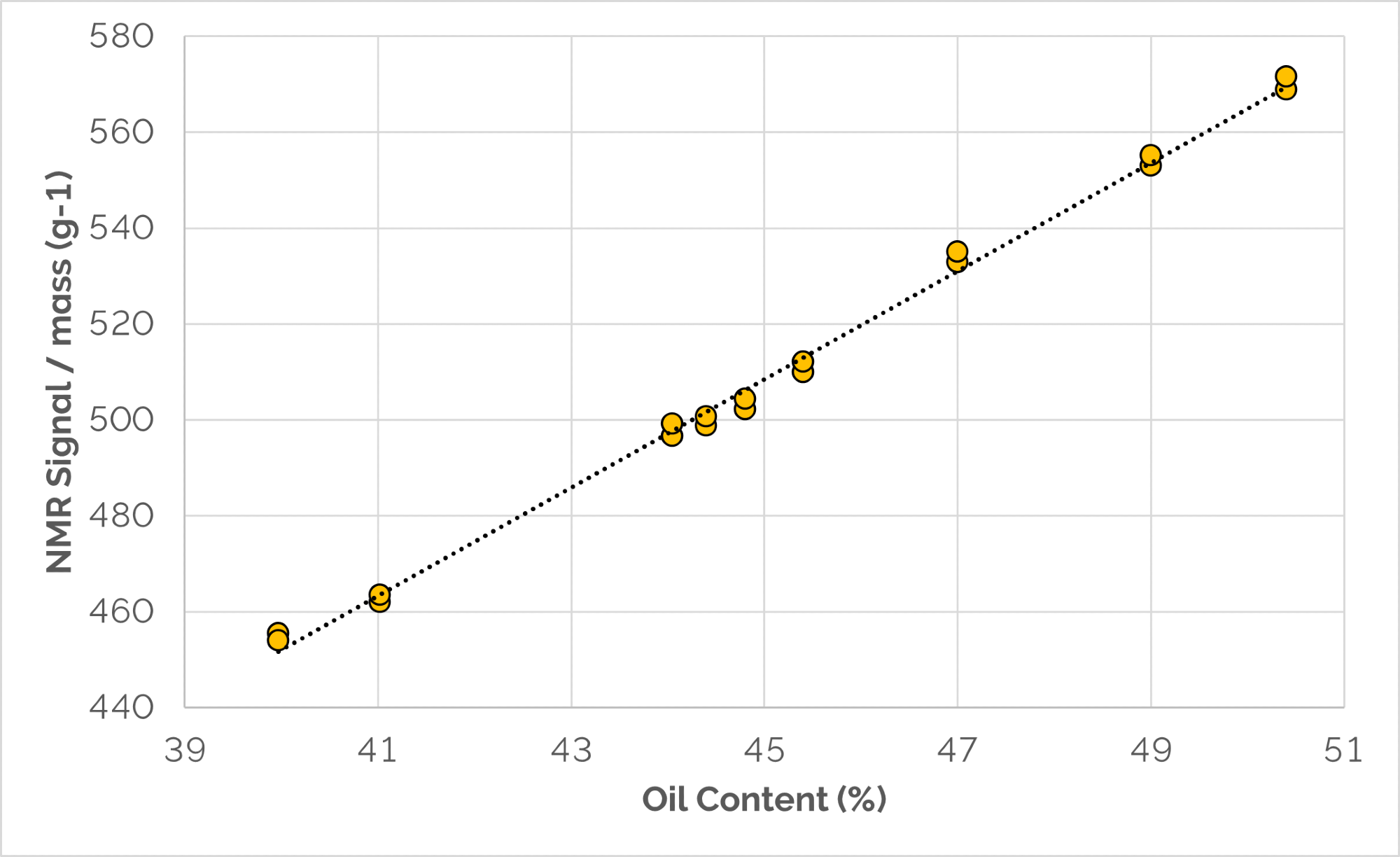

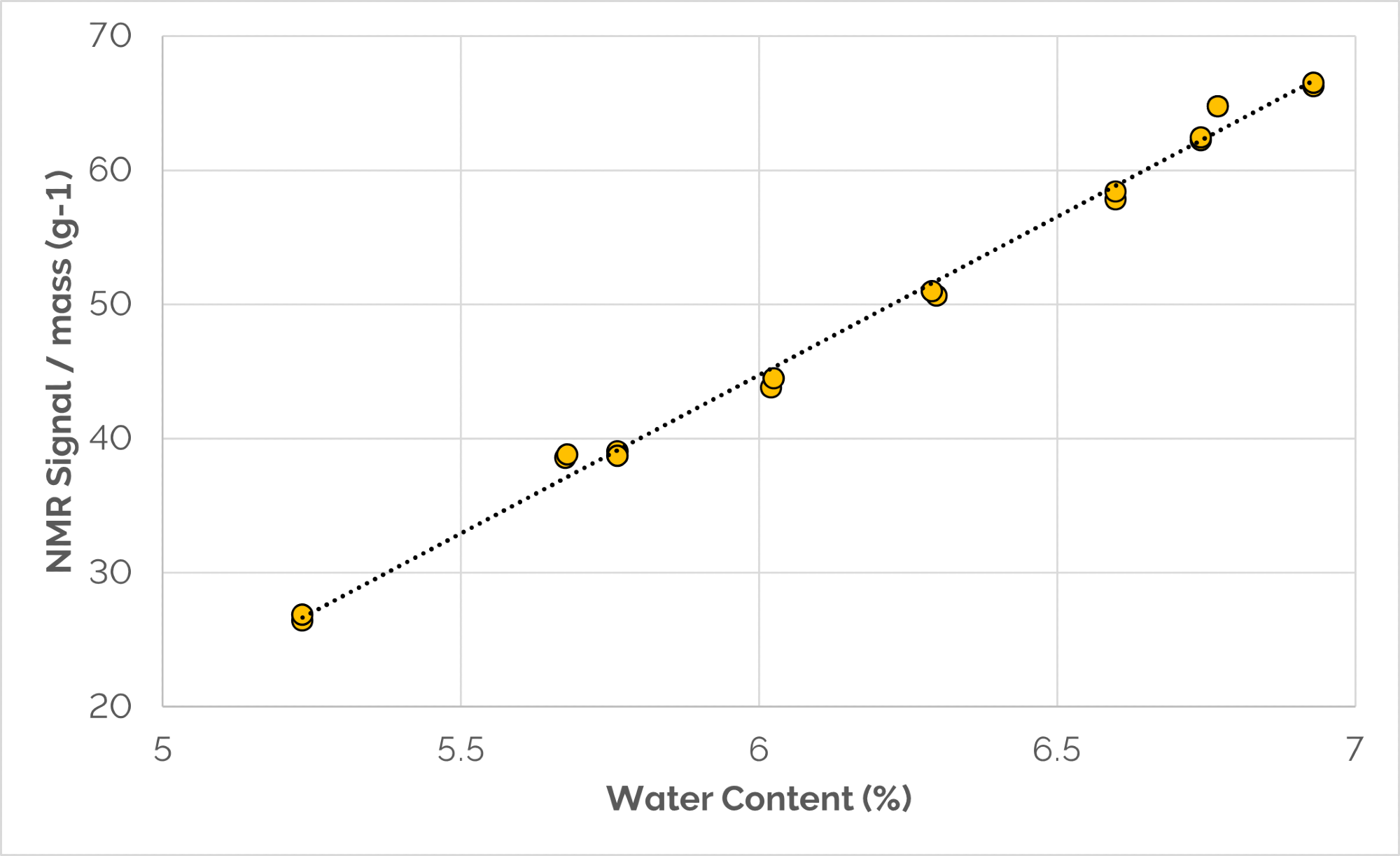

Nine independently analyzed rapeseeds were measured. Their oil contents ranged from 39 % to 51 % and their water contents ranged from 5.2 % to 7.1 %. Calibrations for oil and water were established according to ISO 10565, utilizing Oxford Instruments’ MultiQuant software, which enables concurrent measurement of up to four sample parameters.

In addition to oil and water content, it is also possible to quote oil per dry weight and normalized to a specified water content (e.g., 8 or 9 %). The resulting calibrations are illustrated in Figures 1 and 2.

Figure 1. Calibration of oil content of rape seeds in the presence of water (Standard deviation 0.14 %). Image Credit: Oxford Instruments

Figure 2. Calibration for water content of rape seeds in the presence of oil (Standard deviation 0.12 %). Image Credit: Oxford Instruments

Instrument repeatability for oil was then evaluated by measuring a single sample ten times without removing it from the instrument. Sample reproducibility for oil content was assessed by measuring five different portions of the same sample.

Instrument repeatability was demonstrated to be 0.03 %, while sample reproducibility was 0.24 %, reflecting variations in seed oil content distribution within each portion. Results from both experiments are illustrated in Table 1.

Table 1. Instrument repeatability and sample reproducibility. Source: Oxford Instruments

| Value |

Repeat Measurements |

Mean |

SD |

| 44.25 |

44.29 |

44.25 |

44.22 |

44.23 |

44.26 |

44.27 |

44.22 |

44.23 |

44.22 |

44.18 |

44.24 |

0.03 |

| Value |

Portion Measurements |

Mean |

SD |

| 39.5 |

39.7 |

39.2 |

39.4 |

39.5 |

39.8 |

39.5 |

0.24 |

Conclusion

- NMR exhibits excellent long-term stability and rarely requires calibration adjustment.

- NMR is unaffected by air voids between grains or powder.

- Measurement precision is better than wet chemical techniques.

- Sample measurement time is rapid, typically 16 seconds.

- The NMR method is non-destructive, allowing repeated measurements of the same sample before analysis by other methods.

Additional Advantages of the MQC+ System:

- Probes can be removed easily without tools for cleaning or changing probe sizes.

- The auto-weighing function used on the MQC+5 increases sample throughput, enabling measurements without manual keyboard or mouse input.

- Automatic post-measurement calculation of oil content relative to dry weight, 9 %, or other water content reduces workload.

- The ability to import and export data allows the instrument to fit in existing systems.

Image Credit: milart /Shutterstock.com

Oxford Instruments provides various packages specifically designed for oil and water determination in oilseeds and their residues (pressed cake or meals). Two instruments are suitable for this application, both compliant with the industry standard ISO 10565 for a wide variety of sample volumes (given in brackets):

For large sample/seed analysis

- MQC+5 with 51 mm (80 mL), or 40 mm (40 mL) diameter probes.

For small, low-quantity or single-seed analysis

- MQC+23 with 26 mm (14 mL), 18 mm (7 mL), or 10 mm (1 mL) diameter probes.

Image Credit: Oxford Instruments

Image Credit: Oxford Instruments

This information has been sourced, reviewed, and adapted from materials provided by Oxford Instruments.

For more information on this source, please visit Oxford Instruments.