Nov 4 2005

Plain old colors are passé. Complex visual effects, such as pearlescence, translucence, iridescence and glitter, help sell many products, including cars, cosmetics, pharmaceuticals and military hardware. A new instrument at the National Institute of Standards and Technology (NIST) makes comprehensive measurements of such appearance properties to help companies calibrate their own tools and control product quality.

Exotic surfaces and coatings may look different depending on illumination or viewing angles, subtleties that cannot be accounted for by traditional characterization methods. Many consumers are familiar with automobile paints that appear to change color with viewing direction. The new NIST device, called a goniospectrometer, automatically measures the color of light reflected from a surface as well as its dependence on the directions of illumination and observation. The device is described in a recent publication.

NIST already offers a heavily used calibration service making less sophisticated measurements with another instrument. The new goniospectrometer will provide more complete data on the reflection of light from a color surface, and will be used for calibrating similar instruments and for research on exotic-appearing materials and coatings. NIST scientists also hope to create a database of measurements of different materials that could be used for modeling surfaces that have complex visual effects. The work is part of a NIST effort to develop accurate measurement methods for reproduction and quality control of appearance attributes, including color matching, by determining the minimum set of illumination and viewing geometries needed to accurately characterize the perceived color.

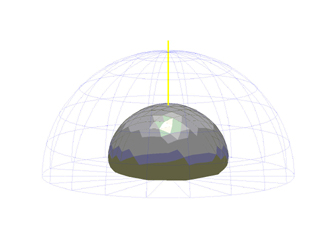

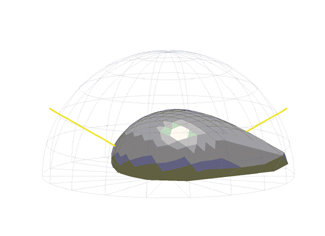

The goniospectrometer, housed in a clean room, illuminates a sample with a range of wavelengths of visible light, every 5 nanometers (nm) from 360 nm to 780 nm, i.e. from the near ultraviolet/deep blue to red/infrared. The sample and detector are rotated around three axes, allowing illumination and viewing in any direction within a hemisphere around the sample (see graphic). The intensity of the reflected beam is measured at several hundred locations on a sample surface. Based on these measurements, computer software assigns a numerical value to the color of the reflected light.

The NIST goniospectrometer measures the intensity of light reflected from the surface of a sample at 332 points. A plot of these measurements results in a different shape depending on whether the illumination comes from above (top) or at a 60-degree angle (bottom).

http://www.nist.gov