Henniker Plasma, a leading manufacturer of plasma treatment systems, announces the launch of its Stratus Plasma Manufacturing Cell range — a fully integrated, turnkey solution that combines advanced atmospheric plasma surface preparation with robotic automation.

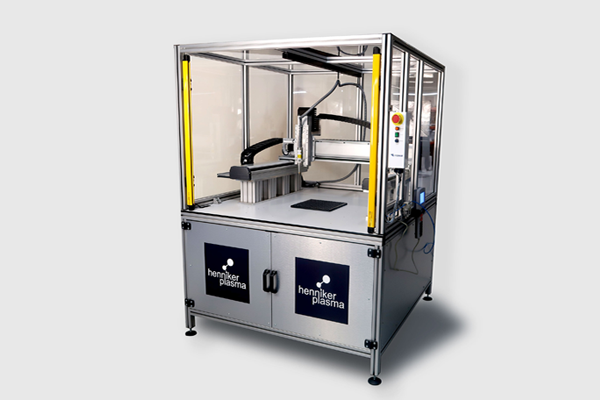

Stratus Series V. Image Credit: Henniker Plasma

Stratus Series V. Image Credit: Henniker Plasma

Stratus systems are designed to deliver high-speed, high-precision surface activation and cleaning for a broad range of materials and applications. From automotive and aerospace to medical device manufacturing, electronics, and battery technology, Stratus unlocks new efficiencies in production environments that demand repeatable and reliable results.

"The Stratus range reflects our commitment to developing practical, plug-and-play plasma solutions that integrate seamlessly into real-world manufacturing workflows," said Terry, Managing Director at Henniker Plasma. "With Stratus, surface treatment becomes not just more effective, but also more accessible, sustainable, and scalable."

Available in multiple configurations with programmable work areas from 200x200 mm to 800x1200 mm and up to 150 mm of z-axis motion, each Stratus system operates over a full 3-axis range. The built-in teach pendant makes setup intuitive even for first-time users, while onboard memory can store hundreds of treatment programs for flexible, multi-part production lines.

Benefits at a Glance

- Improved Adhesion: Plasma increases surface energy, enhancing adhesion of adhesives, inks, and coatings.

- Clean, Activated Surfaces: Removes contaminants and residues for consistent downstream bonding.

- Automated Precision: Integrated robotics ensure efficient, repeatable processing.

- Multi-Material Compatibility: Works on polymers, metals, ceramics, and glass.

Built for Production Environments

Every Stratus cell comes CE-certified and requires only single-phase mains power and compressed air, eliminating the need for additional process gases or infrastructure. The system's proprietary high-stability plasma generator delivers consistent treatment quality, even under continuous operation.

Key Features:

- Plug-and-play operation in minutes

- User-friendly programing via the teach pendant

- Flexible integration into existing workflows

- Compressed air plasma — cost-effective and chemical-free

- Built-in safety systems, including light curtain and self-diagnostics

- Eco-conscious process — no hazardous chemicals, minimal emissions

From surface pre-treatment for coatings and adhesives to precision cleaning of complex parts, the Stratus range provides the performance and reliability demanded by modern manufacturing — all in a compact, easy-to-integrate package.