Researchers at Kaunas University of Technology (KTU) have developed a new class of materials with wide-ranging potential - from medicine and electronics to optics - where cleanliness, precision, and durability are critical.

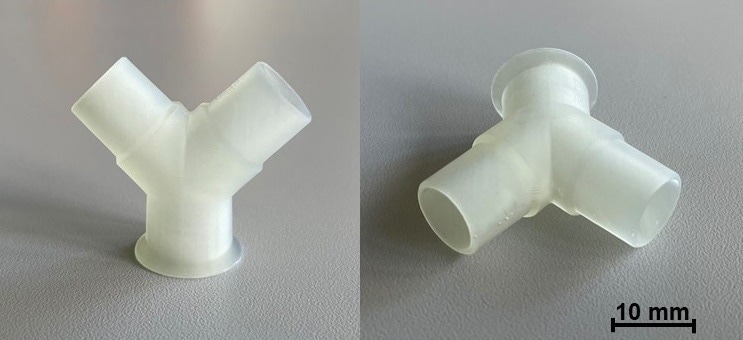

Y-shaped connector successfully printed by KTU scientists. Image Credit: Kaunas University of Technology (KTU)

Y-shaped connector successfully printed by KTU scientists. Image Credit: Kaunas University of Technology (KTU)

What sets these materials apart is not only their advanced functionality but also their sustainability: they’re made from renewable resources, and no solvents are used during production.

Advanced materials can be not only functional, but also friendly to people and the environment. Such work paves the way for technologies that contribute to a safer and more sustainable everyday life.

Jolita Ostrauskaite, Professor, Department of Polymer Chemistry and Technology, Kaunas University of Technology

The materials in question are polymers belonging to a group known as vitrimers. This relatively new category of polymers was first identified about 30 years ago and formally named only 15 years ago. The field has been rapidly gaining interest among scientists worldwide.

A More Sustainable Approach to Vitrimers

Traditionally, vitrimers have been made from petroleum-based materials and required chemical catalysts for processing. The KTU team’s innovation changes that.

“The polymers we have developed are unique because they are made from plant-based compounds, cured under UV or visible light, and do not require catalysts for processing. This happens naturally due to the chemical structure of the material itself,” emphasized the scientist.

This shift isn’t just about simplifying production. Many catalysts are expensive, sourced from non-renewable materials, or toxic. By removing them from the equation, the process becomes cleaner, safer, and more sustainable - while also cutting down on material use and the need for additional additives.

“Vitrimers are thermosetting polymers that, thanks to dynamic covalent bonds, can be thermally reprocessed or reshaped, similar to thermoplastics. At certain temperatures, they can self-heal after damage and also retain a temporary shape that can later be restored – this is known as thermally responsive shape memory,” explained Prof. Ostrauskaite.

The team behind the research includes KTU Ph.D. student Vilte Šereikaite, Dr. Aukse Navaruckiene, and Dr. Sigita Grauželiene - all from the Department of Polymer Chemistry and Technology.

With such capabilities, these polymers fall into the category of smart materials, opening the door to new high-tech applications.

According to Prof. Ostrauskaite, the biggest breakthrough was combining several advanced properties in one material: plant-based composition, light-induced polymerisation, self-healing, shape memory, antimicrobial action, and compatibility with optical 3D printing.

“Such multifunctional and sustainable solutions are still very rare, making this an important step forward both scientifically and industrially,” added the KTU researcher.

Tested in 3D Printing and Medicine

One key area where the material shines is optical 3D printing. The KTU team successfully used it to print complex shapes at room temperature - saving energy and reducing waste. UV or visible light initiates the printing process, allowing for high precision.

“We successfully printed a Y-shaped connector – a typical medical component used to join tubes in infusion or respiratory equipment. This part requires high precision, making it an excellent test of the material we developed,” explained the professor.

The same technique can be applied to other intricate components, such as optical lenses and parts for electronic devices - areas where dimensional accuracy is essential. The polymers can also be shaped into temporary forms that are later reshaped or repaired, making them ideal for prototyping or fast design iterations in industry.

Another standout feature is the material’s antimicrobial properties, which result from specific structural fragments within the polymer.

“The starting compounds used in the study were obtained from plant oils and by-products of biodiesel production, and certain fragments interfere with bacteria and other microorganisms, disrupting their vital functions. This is why such materials can be used to create surfaces or products that must remain clean and hygienic, for example, in medical devices, electronics, sensors, or other items where microbial control is critical,” explained the KTU scientist.

The study was conducted as part of the Lithuanian Research Council-funded project No. S-MIP-23-52, Antimicrobial Shape-Memory Photopolymers from Plant-Based Materials. Collaborators included the State Scientific Research Institute Nature Research Center, JSC 3D Creative, and partners from the University of Upper Alsace in France and Centria University of Applied Sciences in Finland.

Journal Reference:

Sereikaite, V., et al. (2025) Antimicrobial Vitrimers Synthesized from Dipentaerythritol Pentaacrylate and 2-Hydroxy-3-phenoxypropyl Acrylate for LCD 3D Printing. Biomacromolecules. doi.org/10.1021/acs.biomac.5c00577.