The most powerful 3D X-ray microscope models in the ZEISS VersaXRM® series unlock new levels of versatility for both scientific and industrial research.

ZEISS VersaXRM 615 and 730 push the frontiers of non-destructive sub-micron imaging with industry-leading resolution and contrast of intact samples.

Highlights

Extending the Limits of Micro- and Nano-CT Solutions

- High resolution across a comprehensive range of sample types, sizes and working distances

- Advanced flux and faster scans without compromising resolution

- Fast Acquisition Scanning Technology (FAST) for continuous motion scanning for 3D navigation for sub 1-minute whole sample data collection times

- Volume Scout for true 3D navigation

- Breakthrough resolution performance for VersaXRM 730 takes accessibility to the next level with resolution of 450-500 nm across the full range of source voltage, from 30 kV to 160 kV

- ZEISS DeepRecon Pro with AI-based reconstruction technology for up to 10× throughput improvement or superior image quality on unique, semi-repetitive, and repetitive sample workflows, now included with every VersaXRM

- Deep learning for resolution and throughput at full field of view for reconstruction

In situ imaging for non-destructive characterization of microstructures overtime in controlled environments

- Investment protection with upgradeability and extendibility to future innovations and improvements

Highest Resolution and Flux

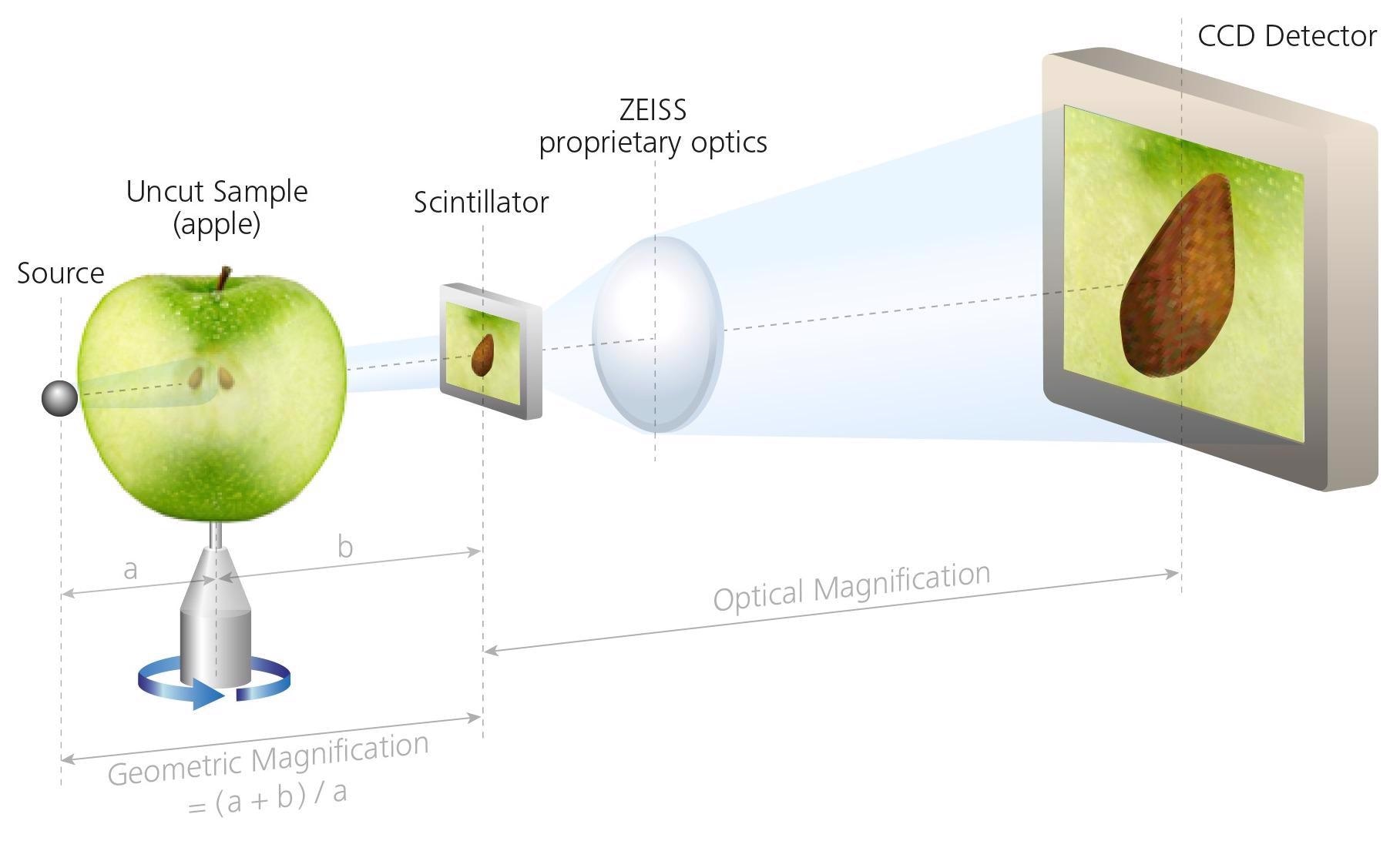

ZEISS VersaXRM use a combination of novel two-stage magnification optics and a high flux X-ray source to provide faster sub-micron scale resolution images, whereas standard tomography depends on single-stage geometric magnification.

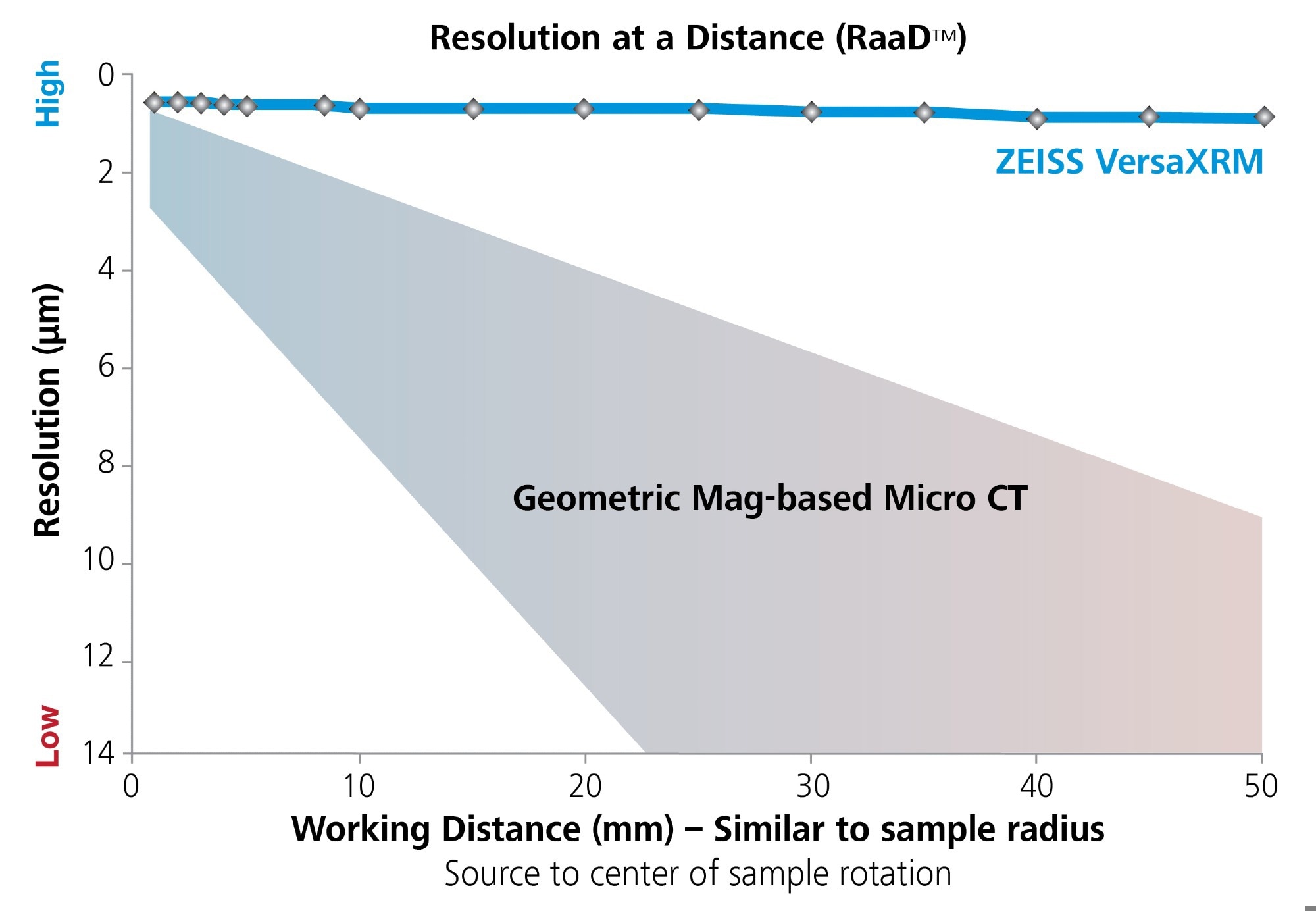

The Resolution at a Distance (RaaD™) architecture allows for high-resolution 3D imaging of larger, denser objects, such as components and electronics that are still intact. Quick scans of very big samples (up to 25 kg) are possible with the optional flat panel extension (FPX), which allows navigation to interior regions of interest.

New Degrees of Freedom

For sophisticated scientific and industrial research, users can employ the industry’s most comprehensive 3D X-ray imaging solution: to get an unprecedented characterization of materials and their properties, maximize absorption and phase contrast. Diffraction Contrast Tomography can reveal 3D crystallographic information.

With sophisticated acquisition techniques, users can improve the speed and precision of scanning big or irregular samples. Utilize machine-learning methods to assist with sample post-processing and segmentation.

Premier 4D/In Situ Solution

The ZEISS VersaXRM Series can describe the 3D microstructure of materials non-destructively in situ (under controlled conditions) and track the evolution of structures over time (4D).

ZEISS VersaXRM retain the best resolution across vast working distances thanks to Resolution at a Distance, which allows it to accommodate both sample, environmental chamber and high precision in-situ load rigs without reducing resolution. To handle multi-scale correlative imaging issues, the Versa works in tandem with other ZEISS microscopes.

Application Examples

ZEISS VersaXRM 615 and 730 at Work

Electronics and Semiconductor Packaging

Typical Tasks and Applications

- Image and analyze microstructures and defects of advanced semiconductor packages, including

2.5D/3D and heterogenous integration packages and chiplets.

- Provide 3D navigational information to assist fast and accurate access to regions of interest

in subsequent physical failure analysis.

- Proven best-in-class applications in failure analysis, packaging development, competitive

analysis, and cybersecurity.

Lithium-Ion Batteries

Typical Tasks and Applications

- Recipe development and supply chain control: Inspection of intact samples for effective supplier

control, revealing changes in recipe or cost savings that may affect performance or longevity

- Safety and quality inspection: Identification of debris, particle formation, burrs at the electrical

contact or damage to the polymer separator

- Lifetime and aging effect: Longitudinal studies of aging effects

Additive Manufacturing

Typical Tasks and Applications

- Detailed shape, size, and volume distribution analysis of particles in additive manufacturing

(AM) powder bed to determine proper process parameters

- High-resolution, non-destructive imaging for microstructural analysis of AM parts

- 3D imaging for comparison with the nominal CAD representation

- Detection of unmelted particles, high-Z inclusions, and voids

- Surface roughness analysis of inner structures that cannot be accessed by other methods

Materials Research

Typical Tasks and Applications

- Characterize three-dimensional structure

- Observe failure mechanisms, degradation phenomena, and internal defects

- Investigate properties at multiple length scales

- Quantify microstructural evolution

- Perform in situ and 4D (time dependent) studies to understand the impact of heating, cooling,

desiccation, wetting, tension, compression, imbibition, drainage and other simulated environmental studies

Geological Research

Typical Tasks and Applications

- Observe and quantify the reality of your rock samples and fossils in 3D

- Gain initial insights of your precious planetary samples

- Understand textural relationships and pore networks

- Perform in situ flooding and imbibition tests to gain knowledge of saturation profiles and reactivity of reservoirs for CCS, CCU, and H2 storage

- Directly measure pore scale, model fluid flow dynamics in core samples

- Automatically segment mineral phases for a full quantitative mineral description of cores

- Improve mining procedures by conducting thermodynamic leaching studies, QA/QC analysis on mining products, such as iron ore pellets, and tailings studies to optimize mining operations and particles

- Evaluate liberation and reactive surface exposure in 3D without the limitations imposed

by stereology

Industrial R&D, Inspection and Quality Control

Typical Tasks and Applications

- Examine the grain alignments of steel and other metals

- Analyze particles combined with full 3D reconstruction

- Study fluid flow and pore structure at various scales, openly monitor fluid flow at the pore scale with in situ flow technologies

- Examine crystal forms with LabDCT Pro

- Non-destructively inspect different part components in an assembly for function and fit

- Image manufactured parts at high resolution for microstructural analysis and quality control

- Compare nominal computer aided design (CAD) model or master part in 3D

- Reverse engineer for manufacturing development to create CAD models from 3D volume data

- Detect defects, particle inclusions, cracks, and unwanted porosity inside plastic and metal parts

- Non-destructively analyze internal features not otherwise accessible to tactile or optical inspection methods

Life Sciences

Typical Tasks and Applications

- High contrast, high resolution 3D imaging of delicate biological samples including mineralized and soft tissues, individual organs and organoids, plant tissues and more

- Study inside specimens histologically, without destroying sample with dissection, down to a cellular level

- 3D imaging of biological samples in their natural environment

- Image delicate plants and animals without sample preparation, processing or sectioning

- Sub-micron photography of whole solid objects such as seeds

- Image plant roots still rooted in their original soil without any special sample preparation

Technology Insights

Non-destructive imaging with the highest contrast and resolution possible.

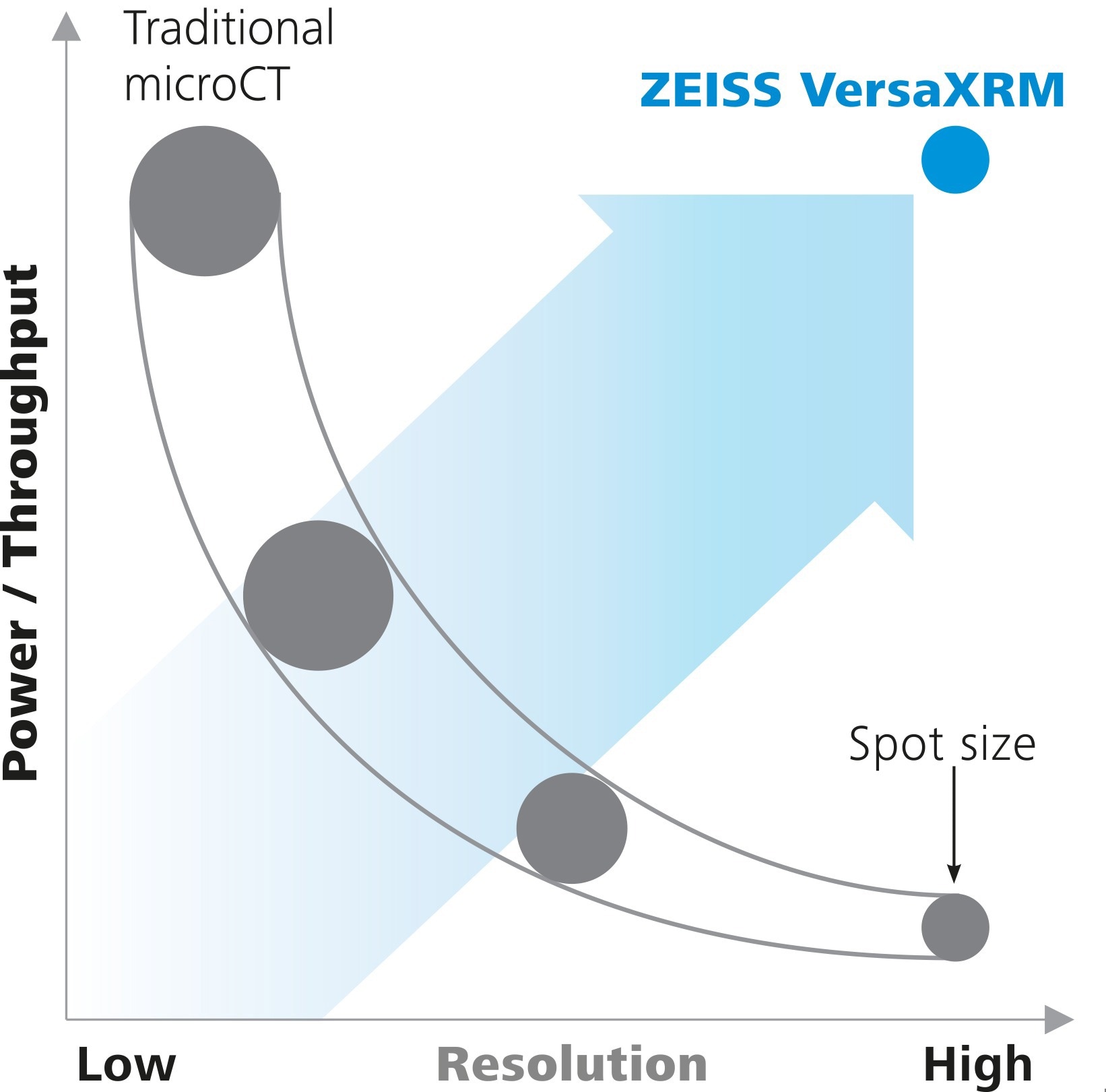

Highest Resolution Without Compromise

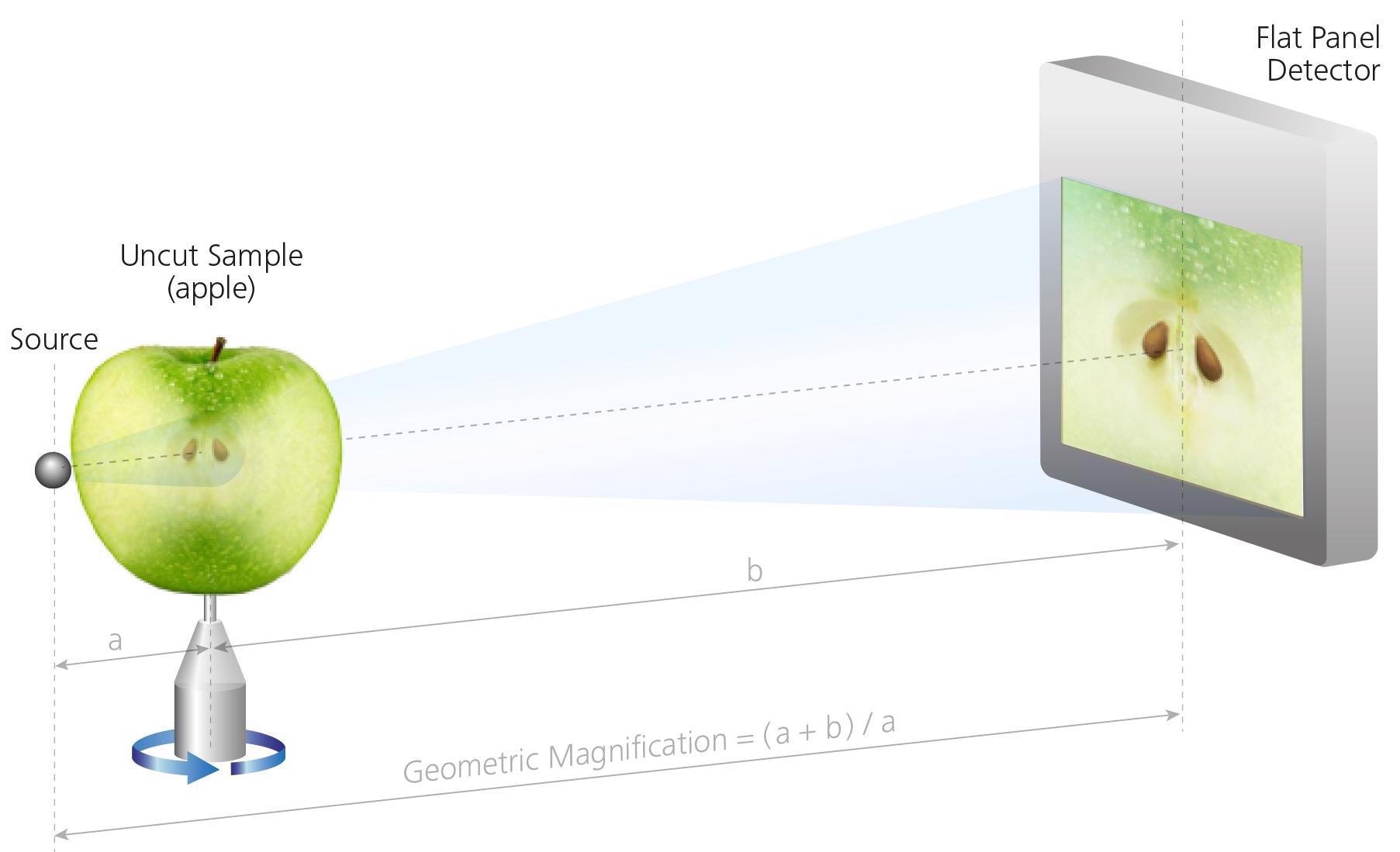

The geometric structure of magnification in standard X-ray computed tomography (CT) limits imaging at high resolution to small sample sizes. Long working distances make it challenging to maintain high resolution for larger samples.

Maintaining excellent resolution for large samples is challenging due to the longer working distances needed. The majority of CT manufacturers promise a maximum resolution, however, its practical application is limited.

The ZEISS VersaXRM Series addresses these trade-offs, which combines high flux X-ray source technology with dual-stage magnification.

ZEISS specifies a true spatial resolution to provide a single measure of microscope effectiveness for 3D X-ray measurement. The smallest difference between two features that an imaging system can rectify is referred to as spatial resolution. Systems from the ZEISS VersaXRM Series may reach a 450-500 nm spatial resolution with voxels as small as 40 nm.

Image Credit: Carl Zeiss Microscopy GmbH

Higher X-Ray Flux Source

Numerous Advantages

With its innovative high-power (25 W) X-ray source technology, the ZEISS VersaXRM Series substantially increases X-ray flux over its predecessors.

The potential source pushes the envelope of efficacy with enhanced flux and throughput, resolution efficiency, and thermal management. Improved source responsiveness leads to quicker scan configuration and a more enjoyable user experience, thanks to a new source management system.

What an advanced X-ray flux provides:

- Several sample runs

- More pronounced diffraction patterns

- Workflows for long or multiple scans (in situ, DSCoVer, stitching, DCT, high resolution aspect technology, or HART) are now feasible.

- Faster tomography scans

- Improved contrast-to-noise ratio

- Large areas of interest

ZEISS X-Ray Microscopes

The Versatile Advantage of RaaD

With unique two-stage magnification design, ZEISS VersaXRM offer a wide range of sample sizes and types of sub-micron resolution imaging at long working distances or Resolution at a Distance.

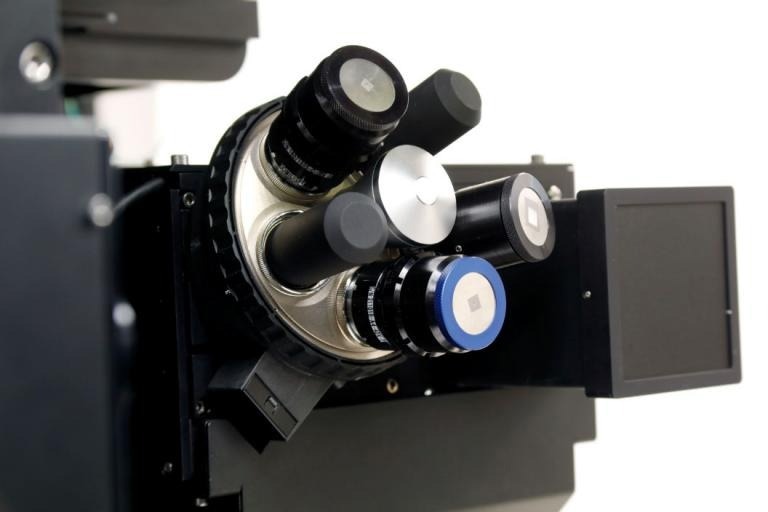

As with traditional microCT, images are first geometrically magnified before being placed onto a scintillator to convert X-Rays into visible range images. These images are then optically magnified with microscope optics and captured by a CCD detector.

The ZEISS VersaXRM Series offers speedy findings for more sample sizes and types without sacrificing resolution because of its increased capacity for X-ray photons.

Additionally, Resolution Performance is about more than just highest specified resolution. With today’s dynamic research demands, high-resolution 3D imaging across the widest range of sample types enables the researcher to see more features in more samples than previously possible. ZEISS VersaXRM 730, with the higher energy capabilities of the exclusive 40× Prime (40×-P) objective, enables research to push the limits of submicron imaging with unparalleled resolution performance.

Image Credit: Carl Zeiss Microscopy GmbH

Conventional Micro CT Architecture

The sample must be close to the source to achieve resolution. Image Credit: Carl Zeiss Microscopy GmbH

ZEISS XRM Two-Stage Magnification Architecture

Sample imaged independently of distance to the source, enabling interiors of larger samples to be imaged non-destructively at higher resolution. Image Credit: Carl Zeiss Microscopy GmbH

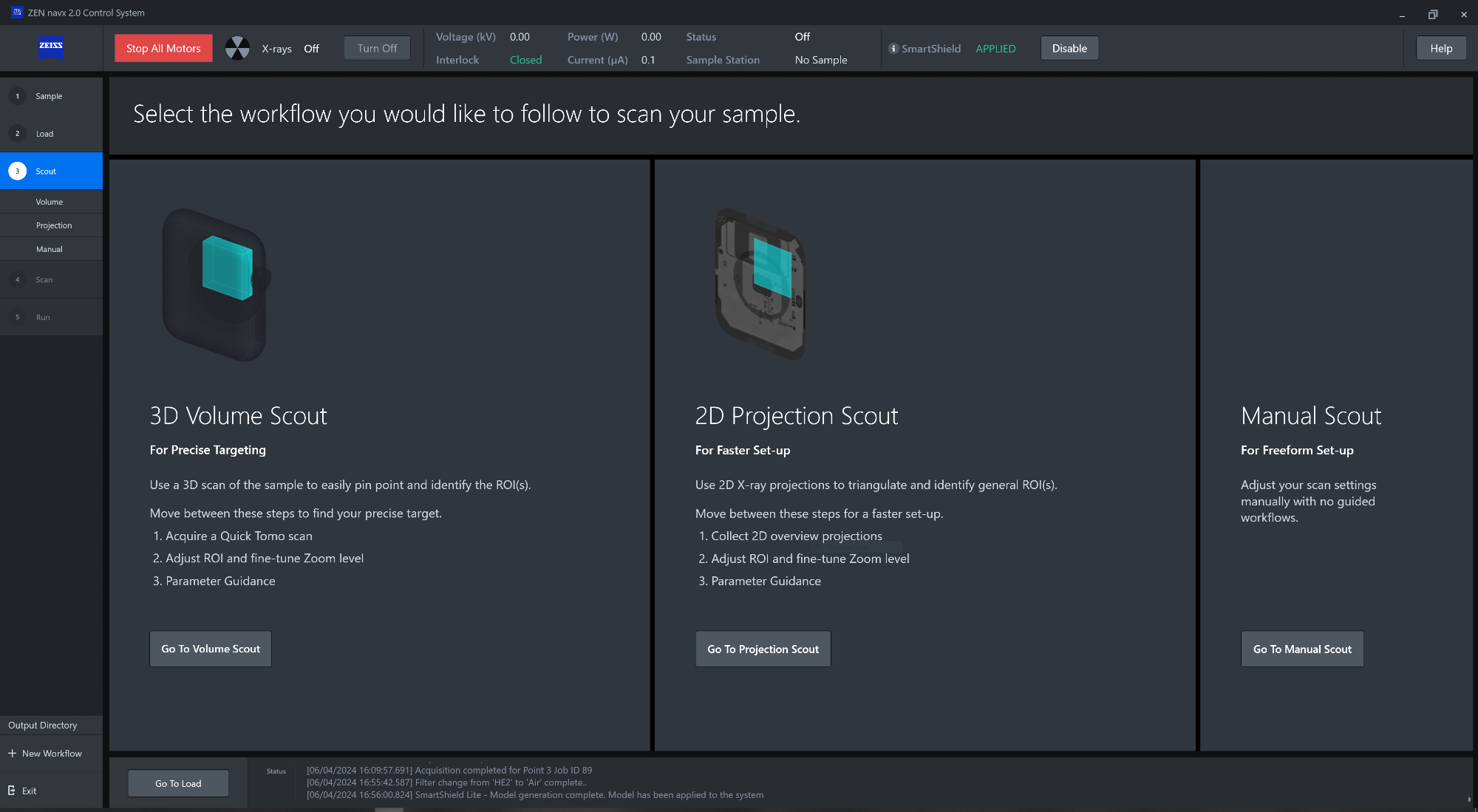

Award-winning Guidance and Control System

The ZEN navx® guidance and control system is based on human-centered design principles, factoring in user habits, biases, and workarounds to deliver an easy-to-use interface that enables immediate success for novice users and an expanded capability for experienced users. Awarded the RedDot Best of the Best Interface award, ZEN navx enables users to automate their workflows and provides instant guidance on the impact the parameters chosen.

ZEN navx guides users through automated workflows with intelligent system insights, streamlining the delivery of experimental results while offering experienced users the flexibility to explore the platform's full capabilities.

With ZEN navx, users can automate workflow and receive information on how the settings selected will affect the setup. The system incorporates this information immediately, guiding decisions comfortably and intuitively.

The ZEN navx File Transfer Utility (FTU) automatically transfers microscope-generated data to other locations, ensuring users can access their data wherever and whenever needed. These enhancements significantly enhance ZEN navx's capabilities for remote operation, thereby boosting user productivity.

ZEN navx offers intuitive navigation, evolving alongside the XRM user base to revolutionize X-ray navigation and control. It seamlessly integrates workflows, enhancing the planning and execution of advanced correlative workflows.

ZEN navx Workflow Selection, for novice to advanced users. Image Credit: Carl Zeiss Microscopy GmbH

Accessories

Increase the number of options available for 3D advanced material characterization.

Breakthrough Resolution Performance to Expand Research Horizons

ZEISS 40x-Prime Objective

With increased X-ray photon availability on the ZEISS VersaXRM series, achieving faster time-to-results for diverse samples is now possible without sacrificing resolution. Exclusive to the ZEISS VersaXRM 730 is the 40x-Prime (40x-P) objective lens.

ZEISS VersaXRM 730, featuring the enhanced energy capabilities of the exclusive 40x-P objective, empowers users to push the boundaries of submicron imaging to unprecedented levels. Renowned for their Resolution at a Distance (RaaD™) capability, ZEISS Versa platforms facilitate high-resolution imaging of various sample types and sizes across an extensive range of length scales.

Resolution Performance is defined by the system's unmatched capability of 450–500 nm with 40x-P over the whole source voltage range of 30 kV to 160 kV. The ZEISS 40x-P objective pushes industry standards for submicron imaging resolution with the ZEISS VersaXRM 730, opening up new application options for researchers.

Head of objectives with the 40x-P (blue). Image Credit: Carl Zeiss Microscopy GmbH

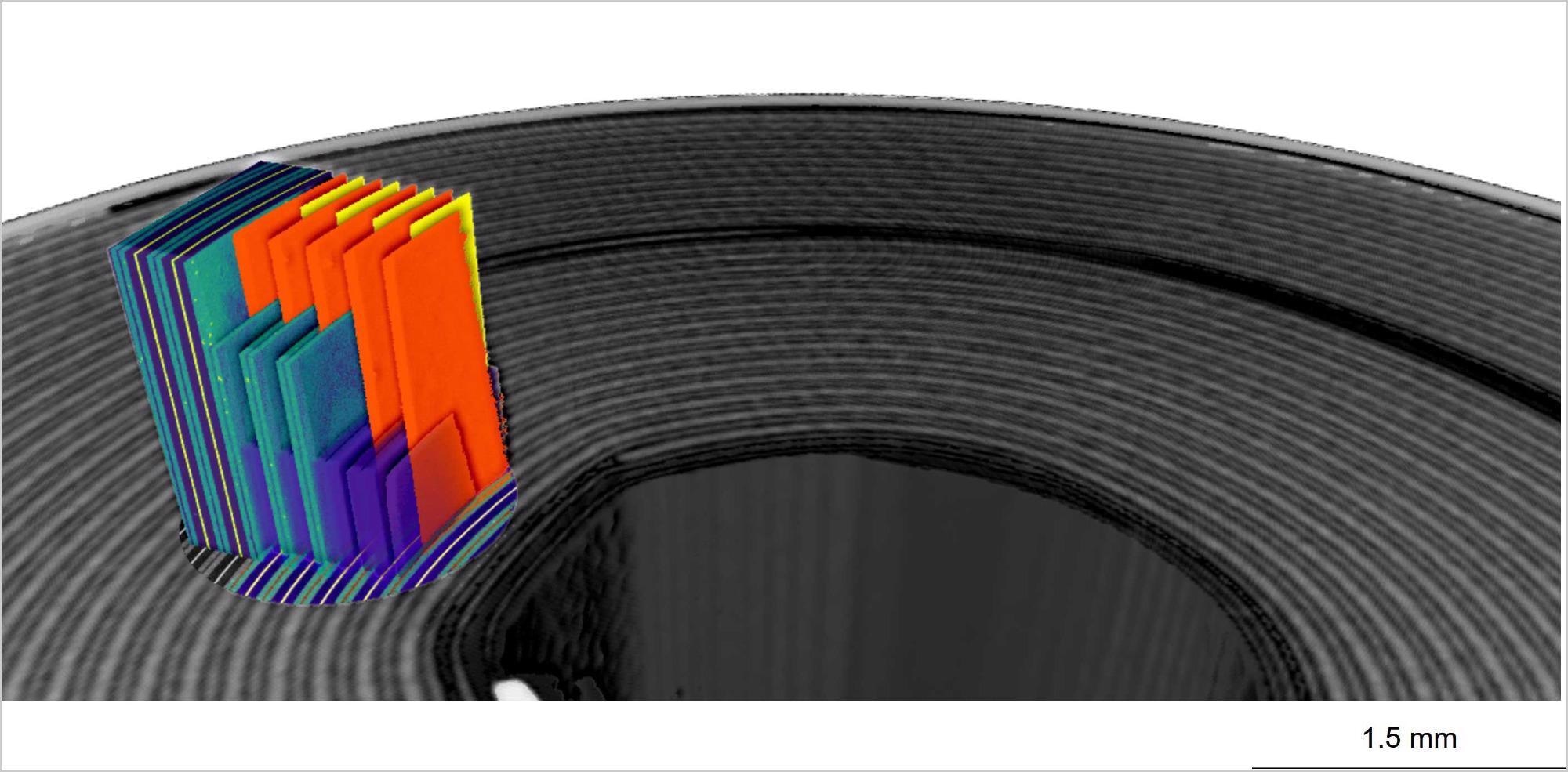

LabDCT Pro

Unlocking Crystallographic Information

Diffraction contrast tomography (DCT) with LabDCT Pro allows for non-destructive 3D imaging of grain alignment and microstructure; this feature is exclusive to the ZEISS VersaXRM 730.

The precise visualization of three-dimensional crystallographic grain orientation enhances the characterization of polycrystalline materials, such as metal alloys, geomaterials, ceramics, and pharmaceuticals.

- Combine modalities to understand structure-property interactions.

- Using 4D imaging experiments to investigate microstructural evolution

- Integrate 3D microstructural data with 3D crystallographic data.

- Specimens having crystal structures ranging from lower symmetry systems, like monoclinic materials, to cubic symmetry can be used with LabDCT Pro.

- Obtain comprehensive 3D microstructure analysis using various sample forms and larger representative volumes.

- Gather high-resolution crystallographic data using the specialized 4X DCT objective.

- Utilize the Flat Panel Extension to increase throughput and big area mapping for even larger samples (FPX)

Flat Panel Extension

With High Throughput, Image Significantly Larger Samples

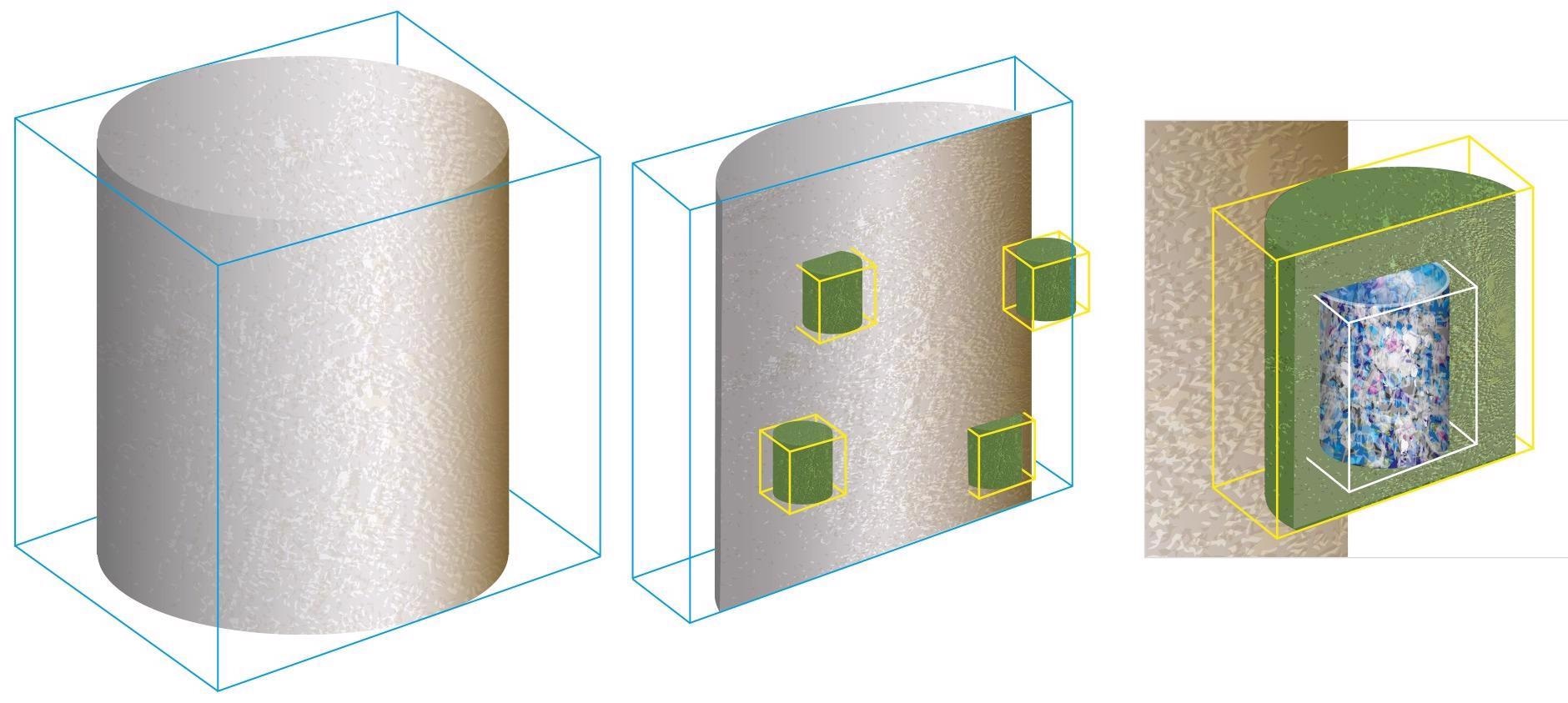

The greatest image quality possible from ZEISS can be achieved with large-sample, high-throughput scanning with the optional Flat Panel Extension (FPX). With a feature-rich solution for business and academic research, FPX improves workflow efficiency and image adaptability.

Scout-and-Zoom is a ZEISS X-ray microscope capability that leverages FPX to conduct exploratory "Scout" scans across a wider range, enabling the identification of interior objects of interest for subsequent higher resolution "Zoom" scans, all without the requirement for intricate sample processing.

Volume Scout, enabled by FPX and embedded in ZEN navx, streamlines access to RaaD with a 3D volume of the sample to pinpoint and identify specific regions of interest to target for higher resolution imaging.

LabDCT Pro's high throughput and broad area mapping capabilities are also available with FPX.

Three-stage Scout-and-Zoom workflow. Image Credit: Carl Zeiss Microscopy GmbH

in situ Experiments

Push the Limits for Scientific Development

ZEISS Versa systems are industry-leading 3D imaging solution tailored for various in situ rigs, including high-pressure flow cells, strain, pressure, and heat stages.

Expanding research beyond the traditional three dimensions of space, 4D experiments leverage the non-destructive capabilities of X-Ray analysis to extend investigations into the dimension of time. ZEISS Versa XRM platforms offer a diverse array of in situ rigs, including highly pressurized flow cells, tension, compression, and temperature stages, as well as customizable designs to accommodate user-specific requirements.

ZEISS VersaXRM can be enhanced with an optional in situ Interface Kit, featuring a robotic integration package, comprehensive wiring guidance, additional facilities such as feed-throughs, and recipe-based software for seamless operation directly within the Scout-and-Scan user interface.

Upgrade ZEISS Versa XRM to a VersaXRM 615 or 730 X-ray microscope to harness the advantages of Resolution at a Distance (RaaD) technology. This innovation maximizes efficiency in tomographic imaging of samples within in situ chambers or rigs, particularly when the resolution limits of in situ studies need to be extended.

Tensile testing of laser welded steel under increasing load. Image Credit: Carl Zeiss Microscopy GmbH

SmartShield

Protect the Sample Easily to Optimize Experiment Setup

SmartShield, included with the ZEN navx guidance and control system, is a comprehensive solution that safeguards both the sample and the microscope. This collision avoidance system operates seamlessly alongside the Scout and Scan Control System, empowering users with enhanced management capabilities for Xradia Versa. By simply pressing a button, SmartShield generates a digital protective coating tailored to the dimensions of the sample, ensuring greater confidence in operation.

SmartShield offers the following benefits:

- Superior scan clarity

- Safeguarding important samples and investments

- Better operator efficacy is made possible by an easy sample setup

- Improved usability for both inexperienced and seasoned users

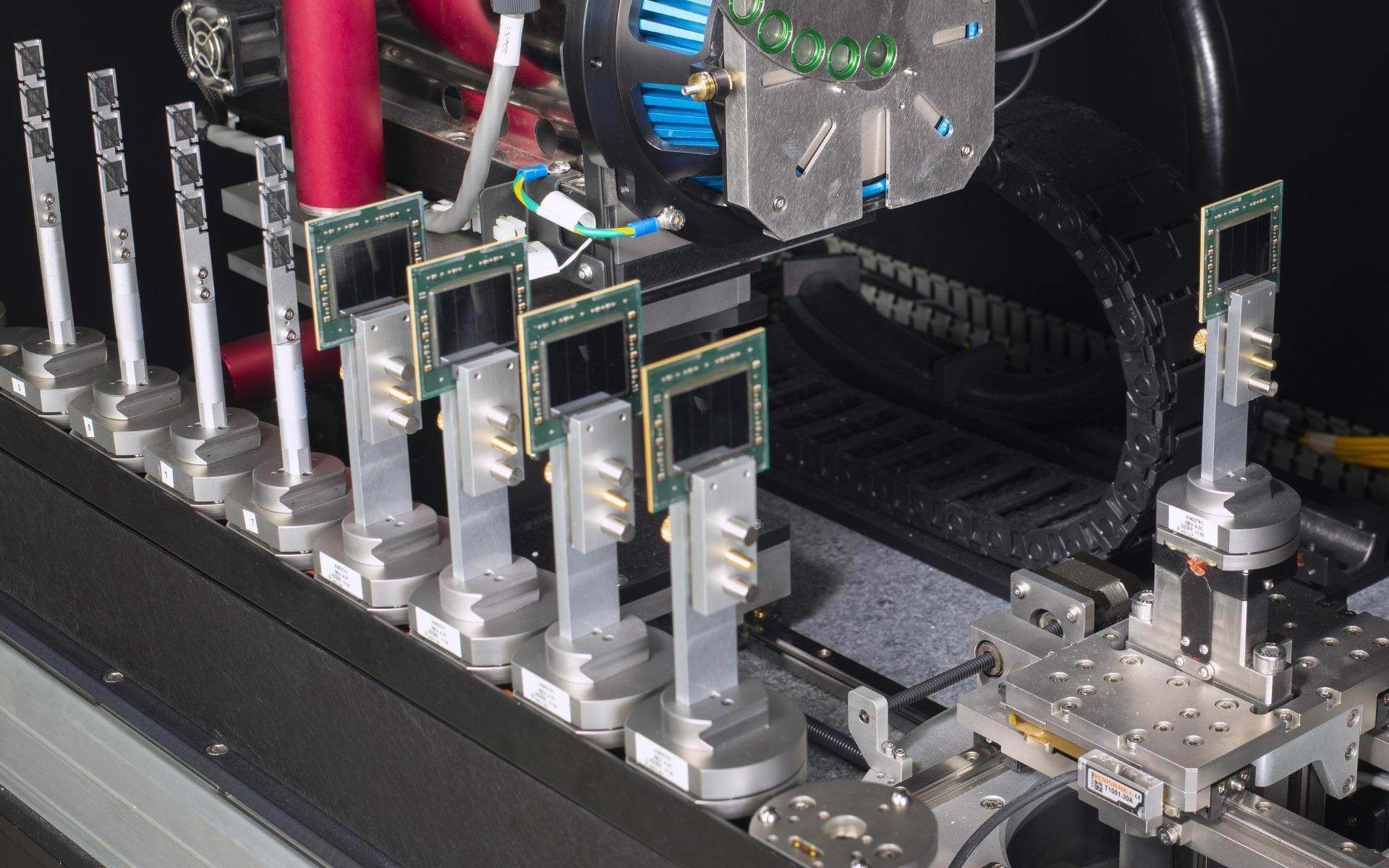

Autoloader

Improve the Efficiency of Sample Handling

Enhance the instrument's usability by incorporating the optional Autoloader, which is compatible with all ZEISS Versa X-ray microscope platforms.

By queuing many jobs at once, users can increase efficiency while reducing the frequency of engagement. Up to 14 sample stations, each holding 70 samples, can be loaded and set to run for a few days or overnight.

High-volume quantitative recurrent scanning of identical samples is made possible by mechanical stability that has never been seen in the industry before.

The autoloader option enables the programming of up to 70 samples at a time to run sequentially. Image Credit: Carl Zeiss Microscopy GmbH

Wide Field Mode

Image Larger Samples with Greater Flexibility

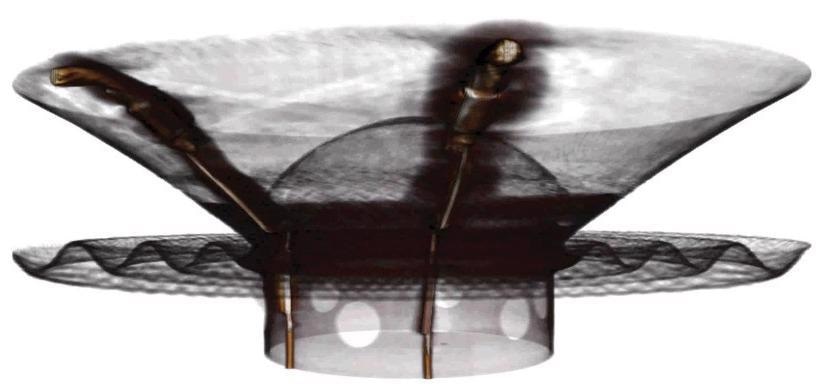

Wide Field Mode is required for users to take pictures with a strong lateral visual field (WFM). For big samples, the wide lateral field of view can offer a 3× larger 3D volume or a higher voxel density than a basic field of view.

ZEISS VersaXRM 730 features Wide Field Microscopy (WFM) with the 4× objective. When paired with Vertical Stitching, WFM empowers users to capture high-quality images of larger samples.

Image large samples with Wide Field Mode like this 6” stereo speaker. Image Credit: Carl Zeiss Microscopy GmbH

Automated Filter Changer

Simplify the Examination of Difficult Samples

To enhance contrast, X-ray source attenuation filters are employed to adjust the X-ray energy spectrum, emphasizing the sample's characteristics, which depend on its unique material properties. Each ZEISS VersaXRM is equipped with a standard set of 12 filters.

ZEISS VersaXRM 615 features a single filter slot for manual shifting. Meanwhile,VersaXRM 730 systems incorporate an Automated Filter Changer (AFC), ensuring effortless filter adjustments to facilitate the investigation of unknown materials.

The Automated Filter Changer (AFC) offers 12 standard filters with room for 12 custom filters. Image Credit: Carl Zeiss Microscopy GmbH

The ZEISS VersaXRM Series

Source: Carl Zeiss Microscopy GmbH

| |

ZEISS VersaXRM

615 |

ZEISS VersaXRM

730 |

| Spatial resolutiona |

500 nm |

450 nm |

Resolution at a Distance (RaaD™)a,b

(at 50 mm working distance) |

1.0 μm |

700 nm |

Minimum Achievable Voxelc

(Voxel size at sample at maximum magnification) |

40 nm |

40 nm |

| Source Voltage Range |

30–160 kV |

30–160 kV |

| Sealed Transmission, Fast Activation Source Power Output |

25 W |

25 W |

| ZEN navx® Guidance and Control System |

✓ |

✓ |

| Scout-and-Zoom |

✓ |

✓ |

| ART DeepRecon Pro with High Performance Workstation |

Optional |

Optional |

| ART DeepScout, PhaseEvolve, MARS, OptiRecon modules |

Optional |

Optional |

| SmartShield and Volume Scout |

✓ |

✓ |

| Vertical Stitch |

✓ |

✓ |

| XRM Python API |

✓ |

✓ |

| Automated Filter Changer (AFC) |

|

✓ |

| High Aspect Ratio Tomography (HART) |

|

✓ |

| Dual Scan Contrast Visualizer (DSCoVer) |

|

✓ |

| Wide Field Mode |

|

4x |

| ZEISS LabDCT Pro for Diffraction Contrast Tomography |

|

Optional |

| ZEISS Autoloader |

Optional |

Optional |

| In Situ Interface Kit |

Optional |

Optional |

| ZEISS ZEN Intellesis |

Optional |

Optional |

| ORS Dragonfly Pro |

Optional |

Optional |

| FAST Mode, enabled, FPX required |

Optional |

Optional |

aZEISS 2D resolution target, normal field mode, and optional 40× objective were used to test spatial resolution.

b The RaaD™ working distance is defined as the clearance around the rotating axis.

c Voxel is a geometric word that adds to resolution but does not determine it, and is used solely for comparative purposes. The genuine overall measurement of instrument resolution, as defined by ZEISS, is spatial resolution.

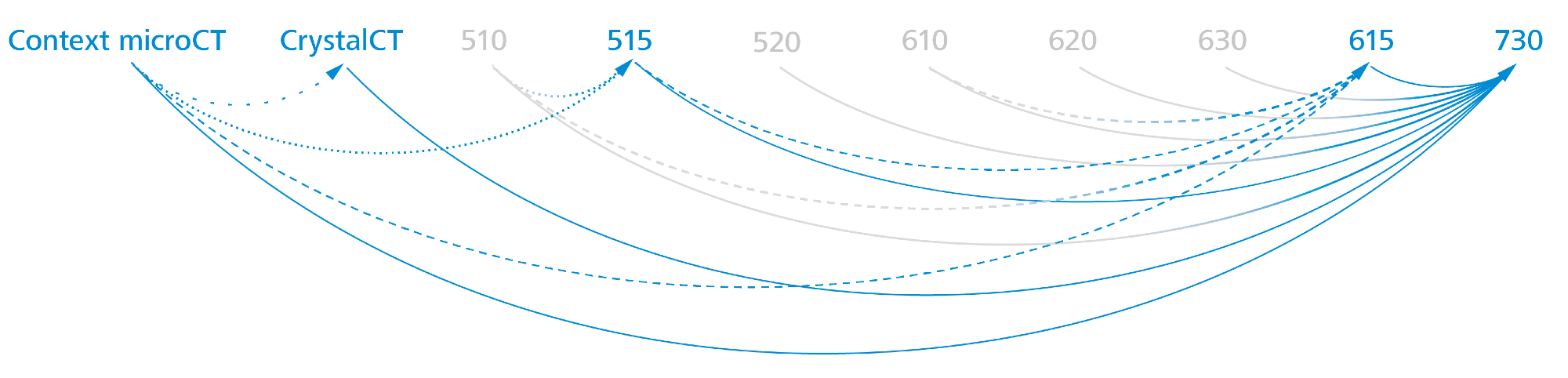

Investment Protection

To safeguard customers' investments, ZEISS X-ray microscopes are designed to be adaptable and expandable with future innovations and breakthroughs. This ensures that advancements in cutting-edge technology will be reflected in the microscope's capabilities.

Customers can field-convert their systems to the newest X-ray microscopes from ZEISS Context microCT, ZEISS CrystalCT, ZEISS Xradia 510/515/520 Versa, ZEISS Xradia 610/620 Versa, up to ZEISS VersaXRM 730.

Image Credit: Carl Zeiss Microscopy GmbH

Software

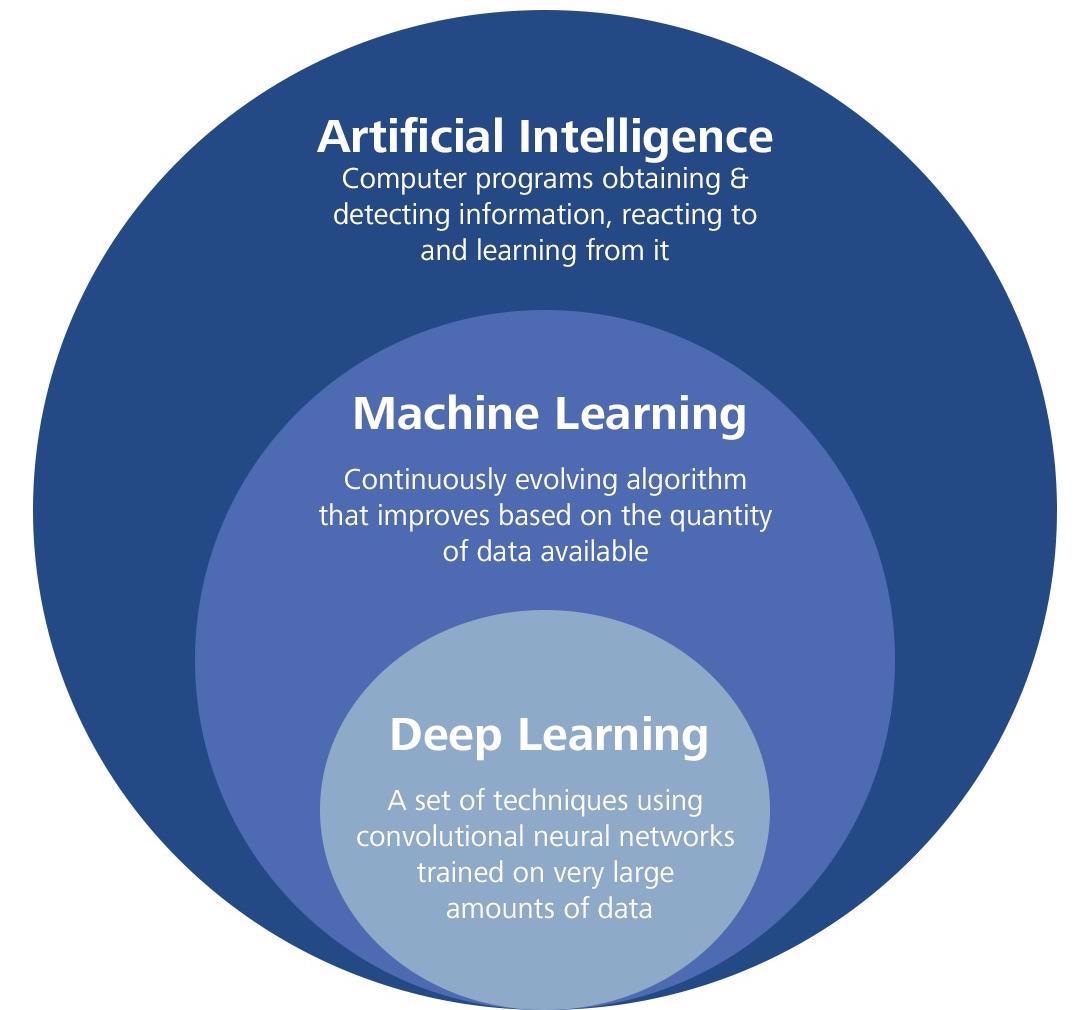

ZEISS Advanced Reconstruction Toolbox

Increased throughput and better image quality.

Image Credit: Carl Zeiss Microscopy GmbH

Advanced Reconstruction Toolbox (ART) introduces Artificial Intelligence (AI)-driven reconstruction methods on the ZEISS 3D XRM or microCT. By gaining a deeper comprehension of X-ray physics and applications, users can tackle even the most challenging imaging challenges in fresh and creative ways.

Users can investigate how ART's proprietary modules, DeepRecon Pro, DeepScout, PhaseEvolve, and OptiRecon improve data gathering, reconstruction speed, and image quality without compromising resolution.

The user can employ the Advanced Reconstruction Toolbox to:

- Enhance the contrast-to-noise ratio to reveal tiny differences

- Attain improved throughput or internal tomography on a variety of samples.

- Obtain an order of magnitude increase in sample class speed that requires repetitive workflow.

- Improve data collection and analysis to enable quicker and more accurate decision-making.

- Boost the quality of the image

DeepRecon Pro and a high performance workstation are included with VersaXRM 615 and 730 for higher throughput or image quality improvements. Optional modules are workstation or cloud-based solutions for easy accessibility and usability:

- DeepScout for full-volume, high resolution imaging

- PhaseEvolve to enhance contrast

- Materials Aware Reconstruction Solution (MARS) for sample awareness

- Iterative reconstruction with OptiRecon

ZEISS DeepRecon Pro provides a straightforward, uncomplicated, and powerful application of AI and deep neural network technology for enhancing X-ray tomography results without prior knowledge of deep learning technology. It helps us to reduce the scan time required for in situ fluid-rock interaction experiments when we need to work with long exposure times.

Dr. Markus Ohl, X-Ray Microscopy, EPOS-NL MINT, Utrecht University

ZEISS Mineralogic - Automated Mineralogy

ZEISS SEM, XRM, and microCT devices can be used for phase identification and textural analysis in 2D and 3D.

Image Credit: Carl Zeiss Microscopy GmbH

Visualization and Analysis Software

ZEISS suggests using the state-of-the-art analysis and visualization software 3D World ZEISS edition Powered by Dragonfly for 3D data acquired from several technologies like X-ray, SEM, and FIB-SEM microscopy.

Large-scale 3D grayscale data analysis and visualization are made easy with the extensive, adaptable, and user-friendly 3D World ZEISS edition toolbox only offered by ZEISS. It enables video production, annotation, navigation, and the creation of media files from 3D data. Segmentation, object analysis, and image processing can all be used to assess the outcomes.

Image Credit: Carl Zeiss Microscopy GmbH