The Rapid Visco Analyser from PerkinElmer is an exclusive tool for product development, quality assurance, as well as quality and process control. This cooking and stirring viscometer features variable shear capability and ramped temperature optimized to test the viscous properties of dairy products, grain, starch and other foods.

The instrument can analyze as little as 2 or 3 g of the sample with the help of international standard methods or users’ own custom-developed test routines of measuring, mixing, cooling and heating.

- Relevant: Test routines can be customized to simulate industrial processing conditions

- Rapid Viscosity Profile: Standard starch pasting test can be performed in 13 minutes

- Glass-free: Safe for food production areas

- Easy to use: Automated operation ensures reliability and reduces the need for training

- Calibration: Users can check with traceable standards to conform to ISO9000 and Quality System requirements

Applications

Milling and Baking

Users can test grains for soundness and bug damage, starch pasting quality for batters, bread, cakes, noodles and pasta, fungal amylase, flour amylase, anti-staling, heat treatment of flour, malt amylase, wheat gluten quality, and solvent retention capacity.

Starches and Starchy Samples

Native starches of tubers, roots, grains and others can be subjected to standard and custom starch pasting tests. Users can perform custom high shear and extended temperature tests to track the production and end quality of modified starches for food, feed, pharmaceutical and industrial applications.

Extruded and Cooked Foods

Starch transformation, or “Degree of Cook,” of ready-to-eat snack foods, breakfast cereals, pet foods, animal feeds and aqua feeds can be tested at preconditioner, extruder and finished product stages.

Malting and Brewing

Users can predict safe storage life for malting barley, test fast recording mashing system (and the impact of adding chemicals, enzymes and adjuncts to malts), monitor the advancement of malting and estimate barley malting quality and simulated industrial mashing process.

Dairy

The Rapid Visco Analyser helps test process cheese manufacture and melting profile, the impact of drying temperature on milk protein powders, rennet caseinate rehydration, custard, dairy beverages, ice cream mix and dairy desserts, as well as age thickening of sweetened condensed milk and “Miniature Pilot Plant” small scale manufacture of yogurt.

Formulated Foods

Users can test the viscosity profile of products (ready to use and premixes) like gravy, sauce, mayonnaise, ketchup, dressing, soup and other low-viscosity foods formulated with proteins, starches and hydrocolloids. They can also perform melt tests like chocolate and confectionery and “Miniature Pilot Plant” small-scale emulation of production conditions.

Ingredients

The development of the viscosity of proteins like milk proteins, egg whites, soy products, gelatin and gluten can be tested. Gelling/thickening profile and hydration performance of a system can be tested while cooling to identify the hydrocolloid behavior. Samples can be precisely prepared for other kinds of rheological assessment.

Different RVA Models

RVA 4800

The RVA 4800 is PerkinElmer’s top-of-the-range model that integrates exceptional sensitivity and accuracy, an extensive viscosity range and an extended temperature range (of up to 140 °C). Thus, the RVA 4800 is an ideal tool for carrying out more relevant analyses for a range of applications.

Applications include the performance of ingredients (for example, hydrocolloid and starch) under conditions pertaining to ultra-high-temperature (UHT) pasteurization of dairy and food products, pressure cooking, retorting, extrusion and other aseptic processing conditions.

Image Credit: PerkinElmer Food Safety and Quality

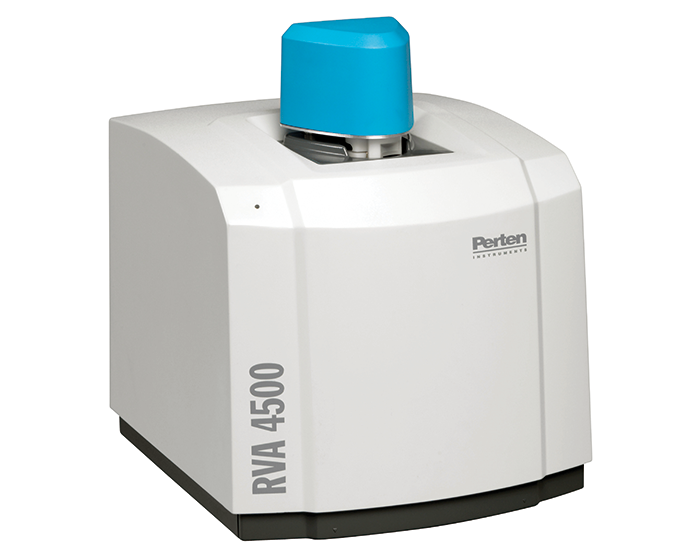

RVA 4500

The RVA 4500 model has been engineered for applications in which the maximum temperature reaches 99.9 °C and delivers the same performance as the RVA 4800.

Image Credit: PerkinElmer Food Safety and Quality

RVA StarchMaster 2

The RVA StarchMaster2 functions as an autonomous system, thanks to four preset methods integrated into the system. It is ideal for raw material testing, production, process control, quality control and quality assurance.

Image Credit: PerkinElmer Food Safety and Quality

RVA TecMaster

RVA TecMaster is a completely featured viscometer that helps analyze a majority of the samples. It works in the mid-viscosity range of 20 to 8,000 cP at 160 rpm. The following are the general-purpose applications of this system: formulated, cooked and extruded foods, starches and starchy samples, proteins, hydrocolloids and “Miniature Pilot Plant” small-scale process emulation.

Image Credit: PerkinElmer Food Safety and Quality