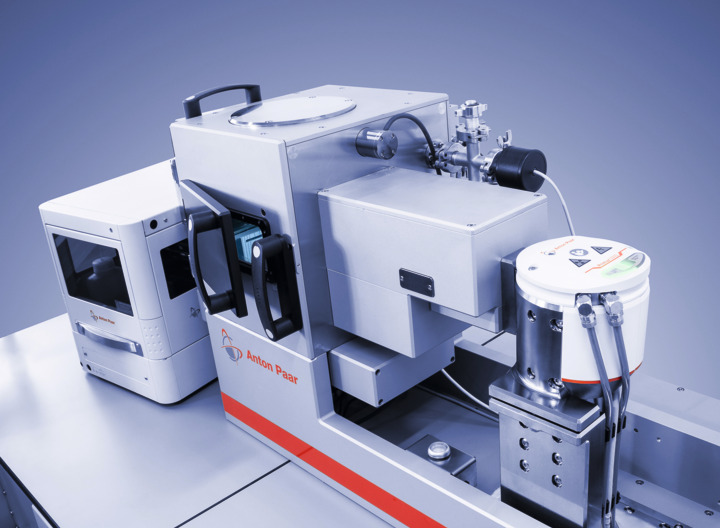

SAXSpace is a compact lab-scale apparatus designed for WAXS and SAXS investigations. The line-collimation beam is designed for rapid examination of isotropic samples.

Specifically designed for isotropic, colloidal, and biological sample (BioSAXS) analysis, it measures the size, shape, and distribution of nano-sized particles and sample domains. High system uptime, automated processes, and a sturdy architecture make SAXSpace ideal for high sample throughput and excellent SWAXS findings.

- Measure the samples directly in a native biological environment

- Increase throughput up to 192 liquid samples

- Small angle X-ray Scattering studies on 1.8 m x 0.9 m footprint

- Study nanostructured materials whenever the user wants

- Perform stability studies on non-ambient conditions

Image Credit: Anton Paar GmbH

Key Features

Speed Up the Daily Lab Work: Optimized for High Throughput

Image Credit: Anton Paar GmbH

The research and characterization of biological samples, such as proteins and enzymes or nanoparticle dispersions, generally necessitates the simultaneous analysis of many samples. SAXSpace is designed to manage up to 192 liquid samples in an automated process. Combined with the ASX autosampler, rapid and exact sampling and efficient cleaning are achieved without user input.

This allows users to take measurements overnight, resulting in complete data sets for analysis the next day. The ASX autosampler comes with a cooling option, which is frequently required for delicate biological samples.

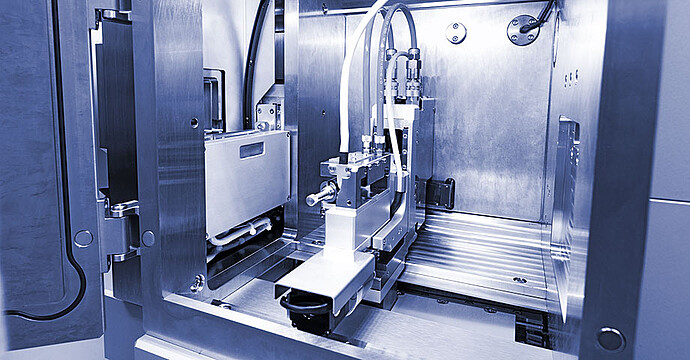

Facilitate SAXS Analysis with TrueFocus and Stagemaster

Image Credit: Anton Paar GmbH

TrueFocus, a completely automated and intelligent self-alignment of all X-ray components and sample stages, allows for alignment at the push of a button.

In parallel, Stagemaster detects which stage is in use and configures the system appropriately. This offers the best possible measurement results without manual procedures and provides users with complete flexibility for their measurements.

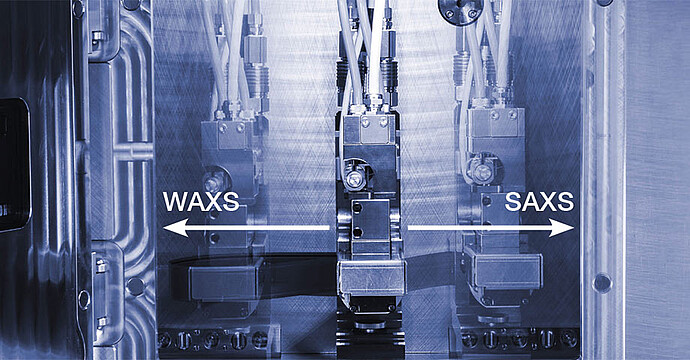

Investigate Structures from the Atomic Level To a Few Hundred nm

Image Credit: Anton Paar GmbH

TrueSWAXS allows simultaneous and continuous SWAXS experiments with a uniform resolution up to 60° 2Ѳ. The collected scattering signal at low angles (SAXS) provides information on large assemblies, such as particle structure and particle/macromolecule assembly, up to a few hundred nanometers, whereas the signal at large angles (WAXS) provides information on the crystalline structure at the atomic level.

The TrueSWAXS feature does all this in one step from the same sample, allowing users to speed throughput for numerous analyses. TrueSWAXS eliminates the need to realign the system, so users can expect consistent resolution and reliable results.

Wide Range of Measurement Options: Versatile Sample Stages

Image Credit: Anton Paar GmbH

The flexible SAXSpace sample chamber provides infinite analysis possibilities and complete experimental freedom. Benefit from a diverse range of sample stages and holders for ambient and non-ambient studies, such as temperature-controlled (-150 °C to 600 °C), humidity-, and defined mechanical load studies, automated measurements of multi-solid/paste-like/liquid samples, and analysis of thin films and nanostructured surfaces (GISAXS).

The sample stages are plug-and-play and recognized by Stagemaster, configuring the system automatically.

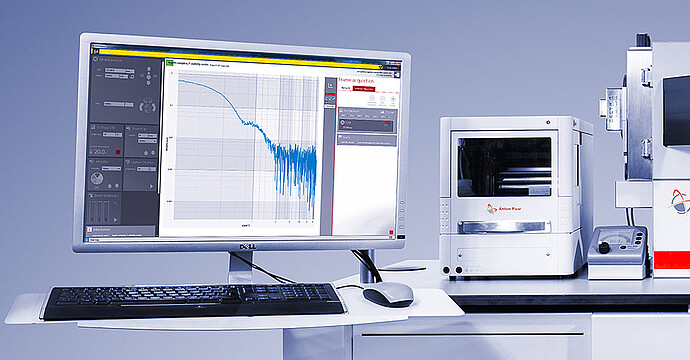

Get Straight to Results

Image Credit: Anton Paar GmbH

Control and analysis of scattering data necessitate strong software solutions. SAXSdrive™ and SAXSanalysis™ automate regular procedures, such as measurement setup and alignment, resulting in thorough data analysis. Utilize serial measurements, automated sampling, temperature scans, and time-dependent studies to examine the obtained 1D and 2D data sets.

SAXSanalysis™ uses established methods to determine characteristics such as radius of gyration (RG), particle size, Porod constant, specific surface, and Kratky plot. IFT and deconvolution methods can be used for advanced structure interpretation (PCG), such as particle size, size distribution, shape, and interior structure.

Technical Specifications

Source: Anton Paar GmbH

| . |

. |

| X-ray source |

Primux 3000 sealed tube (Cu, Mo) |

| X-ray optics |

Custom-designed multilayer optics (fully evacuated)

Advanced scatterless Kratky-based block beam collimation (fully evacuated) |

| Sample stages/Autosamplers |

- TCStages

- Humidity Stage

- Tensile Stage

- GI-SAXS Stage

- ASX Autosamplers

- VarioStage

- Customized stages on request

|

| Special features |

TrueFocus: self-alignment with X-ray beam

TrueSWAXS: simultaneous SWAXS studies up to 60° 2Ѳ

StageMaster: YZ stage with auto-recognition of sample stages |

| System resolution |

qmin: 0.03 nm-1 |

Sample environment

- Temperature range

- Atmosphere |

-150 °C to +600 °C, ±0.1 °C

Vacuum, air, inert gas, humidity

(reactive gases on request) |

| Sample holders |

- Quartz capillary for liquids

- SiN Cell (low parasitics flow-through cell)

- Sample holder for solids

- PasteCell for viscous and powder samples

- RotorCell for sample spinning

- High-pressure cells

- μ-Cell for small sample volumes

- FlowCell/TubeCell for automation

|

| Measurement time |

<1 minute to 30 minutes (typical) |

| Detectors |

1D Mythen2 R series and 2D EIGER R series HPC detectors |

| Accessible q range |

0.03 nm-1 to 40.7 nm-1

200 nm > d > 0.15 nm |

| Software |

SAXSdrive™ measurement and acquisition software

SAXSanalysis™ data processing and analysis software

Advanced data interpretation software (PCG) |

| Dimensions (footprint) |

1.8 m x 0.9 m (L x D) |

SAXSpace: Automated experiments

SAXSpace: Automated experiments. Video Credit: Anton Paar GmbH

SAXSpace: Structural Biology in the Native State

SAXSpace: Structural Biology in the Native State. Video Credit: Anton Paar GmbH