The SVM automatic kinematic viscometer enables accurate and effective viscosity testing.

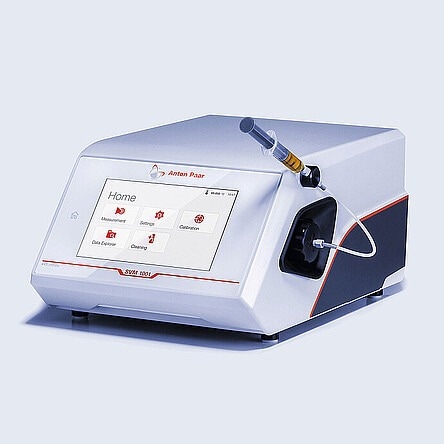

SVM 1001

Image Credit: Anton Paar GmbH

- With just 1.5 mL of sample, obtain digital results in less than five minutes: No more manual calculations or stopwatches

- Take advantage of a market-leading price on an automatic kinematic viscometer.

- Benefit from the small size (battery option available)

-

Choose a temperature between 15 and 100 ℃.

- Instead of using 12 Ubbelohde viscometers, use one unbreakable cell.

SVM 1001 Simple Fill

Image Credit: Anton Paar GmbH

- Take advantage of a small, battery-operated automatic kinematic viscometer.

- Increase throughput by 150 % compared to manual glass capillary viscometers.

- Pour the sample straight into the funnel without using a pipette or syringe.

- Reduce operator effort through automated cleaning and drying.

- Choose a temperature between 15 ℃ and 100 ℃.

SVM 1101 Simple Fill

Image Credit: Anton Paar GmbH

- Complete density measurement that complies with ASTM D4052 and ISO 12185, along with quick viscosity results.

- The market's only budget-friendly multiparameter kinematic viscometer.

- A battery-operated, genuinely portable device that weighs just 6.5 kg.

- Pour the sample straight into the funnel; no syringe or pipette is required.

- The operator time for each measurement is two minutes.

SVM 2001

Image Credit: Anton Paar GmbH

- Measure every sample's viscosity without the burden of selecting the right capillary.

- For kinematic viscosity and density at any temperature in the range of 15 ℃ to 100 ℃.

- Comply with ASTM D396, D975, D3699, D6158, D6823, D7467, and additional norms.

- Upgrade options: Determine density according to ASTM D4052 and the viscosity index.

- A large selection of automated sample changers is available for selection.

SVM 3001

Image Credit: Anton Paar GmbH

- Use the industry's largest temperature range with one measuring cell: -60 °C to +135 °C.

- Without changing capillaries, measure everything from jet fuel to wax, with a single instrument.

- Measure down to -20 °C without using an external counter-cooler.

- Fully compliant with standards, such as SAE J300, J306, ASTM D396, D975, D7666, ISO 23581, and EN 16896.

- For automated multiparameter analyses, combine with Abbemat refractometers and Xsample sample changers.

SVM 3001 Cold Properties

Image Credit: Anton Paar GmbH

- Obtain cloud, freeze point, density, and kinematic viscosity results from a single measurement.

- Perform rapid temperature scans to determine jet fuel’s pumpability behavior.

- Adhere to JIG AFQRJOS, ASTM D1655, D2880, D7566, D975, D7467, and other standards.

- Without warming up in-between, clean and dry at below-freezing temperatures.

- Get cloud and freeze point results equivalent to ASTM D2386 and ASTM D2500.

SVM 4001

Image Credit: Anton Paar GmbH

- The special double-cell design allows simultaneous determination of density and viscosity at any two temperatures between 15 °C and 100 °C

- With just 2.5 mL of the sample, a viscosity index can be quickly obtained in full compliance with ASTM D2270.

- Comply with SAE J300, J306, ASTM D6158, D8029, D2502, and further norms

Key Features

Kinematic and dynamic viscosity, density, cloud point, freeze point, viscosity index (VI), and many other parameters are all determined in a single run by SVM. Exchange all your capillaries for a single device featuring an unbreakable metal measuring cell.

The SVM series offers unsurpassed flexibility, as its measuring cell covers the entire viscosity and temperature range relevant for petroleum products. Enjoy all the advantages of ASTM D7042, and report in both D7042 and D445 using the integrated bias corrections defined by ASTM.

Save Time with the SVM Automatic Kinematic Viscometers

Image Credit: Anton Paar GmbH

- 150 % higher throughput than with manual techniques.

- Rapid measurements enable swift responses to out-of-spec production.

- Temperature equilibration in less than a minute.

- With the Simple Fill funnel, fill the sample or solvent straight out of the container: SVM 1001 Simple Fill and SVM 1101 Simple Fill do not require a pipette or syringe.

Experience Error-Free Digital Data Handling

Image Credit: Anton Paar GmbH

- Digital data recording and storage, and automated computations, ensure mistake-free measurements and traceability.

- Export data to a USB drive or PC.

- Access data from the automatic kinematic viscometer with just one click.

- For digital data management, compatible with AP Connect

Improve Safety for Lab and Operator

Image Credit: Anton Paar GmbH

- Glass breakage is eliminated with a metal measuring cell.

- Peltier thermostating built-in for quick temperature control without the need for a constant temperature bath.

- Decreased exposure to flammable bath liquids or dangerous solvents.

Minimal Sample, Solvent, and Energy Consumption

Image Credit: Anton Paar GmbH

- Low power consumption: 50 W to begin.

- Analysis typically using only 6 mL of solvent and 5 mL of sample.

- Minimal downtime: 30-minute maintenance downtime, two-minute cleaning.

- Documentation efforts for quality control are cut in half.

- No software or external PC is required.

Ensure Compliance and Benefit from Bias Correction

Image Credit: Anton Paar GmbH

- Complies with ASTM D396, D975, D1655, D3699, D6158, D6823, D7467, and other standards.

- ASTM, SAE, ISO, IP, EN, DIN, DEFSTAN, MIL, GB, GOST, and other standards all mention ASTM D7042 as a recognized alternative to D445.

- Both D7042 and D445 results can be reported using the integrated ASTM bias correction.

- ASTM D4052 density measurement included (SVM 1101 Simple Fill / SVM 3001 / SVM 3001 Cold Properties / SVM 4001).

Non-stop Automatic Kinematic Viscometer Measurements

Image Credit: Anton Paar GmbH

- Hundreds of samples can be analyzed daily by robotic lab solutions.

- All-day measurements are possible with both heated and non-heated sample changers.

- A filling and cleaning procedure that is repeatable and unsupervised, even overnight.

Technical Specifications

Source: Anton Paar GmbH

| |

SVM 1001 |

SVM 1001

Simple Fill |

SVM 1101

Simple Fill |

SVM 2001 |

SVM 3001 |

SVM 3001

Cold Properties |

SVM 4001 |

| Patents |

AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) |

AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1), AT 516302 (B1), CN105628550 |

AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) |

AT516058 (B1), US10036695 (B2), CN105424556, EP2995928 (B1) AT516302 (B1), CN105628550 |

| Test methods |

ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896 |

ASTM D4052, ISO 12185 |

ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896

ASTM D4052 (optional) |

ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896 ASTM D4052, ISO 12185 |

ASTM D7042, D445 bias

-corrected, ISO 23581, EN 16896 ASTM D4052, ISO 12185

ASTM D2386 equiv. or better ASTM D2500 equiv. or better |

ASTM D7042, D445 bias-corrected, ISO 23581, EN 16896, ASTM D4052, ISO 12185 |

| Measuring Range |

| Viscosity |

0.3 mm²/s to 5000 mm²/s |

0.3 mm²/s to 1000 mm²/s |

0.2 mm²/s to 30,000 mm²/s* |

| Density |

- |

- |

0 g/cm³ to 3 g/cm³ |

0 g/cm³ to 3 g/cm³ |

| Temperature |

15 °C to 100 °C (one temperature, second temperature optional) |

15 °C to 100 °C |

15 °C to 100 °C |

-60 °C to 135 °C |

-60 °C to 100 °C |

15 °C to 100°C |

| Precision |

| Viscosity repeatability** and reproducibility** |

0.1 % and 0.35 % |

0.2 % and 0.7 % |

0.1 % and 0.35 % |

Density repeatability** and

reproducibility** |

- |

- |

0.00005 g/cm³ and 0.0001 g/cm³ |

0.0002 g/cm³

(0.00005 g/cm² with ASTM D4052 option) and 0.0005 g/cm³

(0.0001 g/cm² with ASTM D4052 option) |

0.00005 g/cm³ and 0.0001 g/cm³ |

Cloud/freeze point repeatability**

and reproducibility** |

- |

- |

- |

- |

- |

<0.5 °C / <0.5 °C and

<2.5 °C / <1.3 °C |

- |

| Temperature repeatability |

0.005 °C |

0.005 °C |

| Temperature reproducibility |

0.03 °C from 15 °C to 100 °C |

0.03 °C from 15 °C to 100 °C |

0.03 °C from 15 °C to 100 °C |

0.03 °C from 15 °C to 100 °C |

| Performance |

| Sample volume min. / typical |

1.5 mL / 5 mL |

3.5 mL / 8 mL |

1.5 mL / 5 mL |

2.5 mL / 6 mL |

| Solvent volume min. / typical |

1.5 mL / 6 mL |

5 mL / 10 mL |

1.5 mL / 6 mL |

2.5 mL / 10 mL |

| Max. sample throughput |

37 samples per hour |

21 samples per hour |

33 samples per hour |

30 samples per hour |

24 samples per hour |

| Features |

| Optional upgrades |

Second temperature |

- |

Automatic VI determination ASTM D4052-compliant density measurement |

Chemical upgrade kit |

- |

- |

| Modularity with Abbemat refractometers 300/500, 350/550, 450/650 |

| Accessories |

Magnetic particle trap (MPT) |

- |

- |

Magnetic particle trap (MPT), hot filling attachment (HFA) |

Magnetic particle trap (MPT) |

| Automation |

- |

Integrated Simple Fill Filling Device |

Optional sample changer +

High-Throughput Platform HTV |

Optional sample changer + High-Throughput Platform HTV |

Optional sample changer

+

High-Throughput Platform HTV |

| Technical Data |

| Data memory |

1,000 measurement results |

| HID (Human Interface Device) |

7 in touchscreen |

10.4 in touchscreen, optional keyboard, mouse, and 2D barcode reader |

| Interfaces |

4 x USB (3 x A, 1 xB) |

4 x USB (2.0 full speed), 1 x Ethernet (100 Mbit), 1 X CAN bus, 1 x RS-232, 1 x VGA |

| Power supply |

At instrument: DC, 24 V /3A, AC adapter 90 VAC to 264 VAC, 47 Hat to 63 Hz, < 75W |

AC 100 V to 240 V, 50 Hz to 60 Hz, 250 VA max. |

| Ambient conditions |

15 °C to 35 °C, max. 80 % r.h. non-condensing |

| Net weight in kg |

5.6 kg |

6.6 kg |

15.9 kg |

17.6 kg |

18.0 kg |

17.8 kg |

Dimensions

(W x D x H) |

26.5 cm x 36.5 cm x 18 cm |

33 cm x 36.5 cm x 20.5 cm |

33 cm x 51 cm x 23.1 cm |

| Trademarks |

SVM (13411996), FillingCheck (6834725), Abbemat (1084545) |

*Viscosity range with chemical upgrade kit from 1 mPa·s to 10,000 mPa·s.

**Attested at the points of the works adjustment or at calibration correction points, not including the uncertainty of the standard

Petronas Lubricants International: Customer Success Story

Petronas Lubricants International: Customer Success Story. Video Credit: Anton Paar GmbH