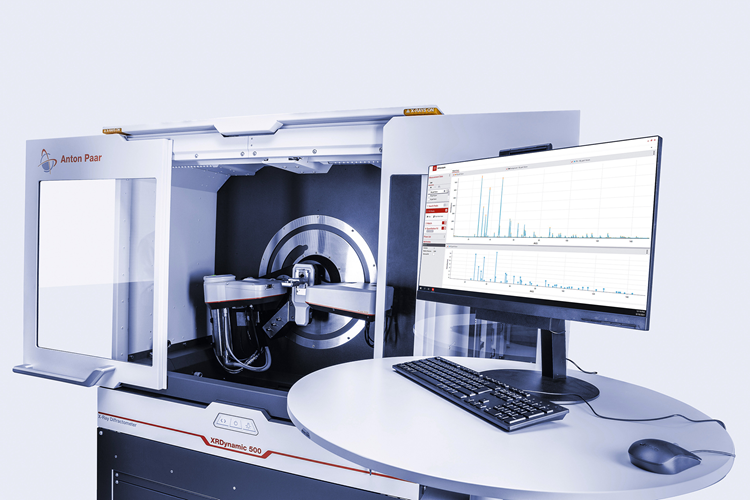

The XRDynamic 500 X-ray diffractometer facilitates exceptional XRD data integrity coupled with heightened productivity. This adaptable platform offers broad application coverage, delivering superior solutions for powder XRD, non-ambient XRD, PDF analysis, SAXS, and other techniques. Its fully automated optics and alignment protocols enable users of all skill levels to acquire high-caliber XRD data rapidly, concurrently diminishing potential inaccuracies.

- Out-of-the-box: Delivers superior resolution and signal-to-noise ratio

- TruBeam™ concept: Features an expanded goniometer radius and a vacuum-sealed beam trajectory

- Full automation: Facilitates changes in X-ray optics and beam geometry

- Efficiency: Boosts instrument utilization by as much as 50 %

- Maximum convenience: Simplifies instrument and sample alignment

Key Features

Unmatched Data Quality

The XRDynamic 500's distinctive TruBeam™ design integrates a wide goniometer radius, a vacuum-sealed beam pathway, and completely automated X-ray optics/beam geometry alteration. TruBeam™ guarantees enhanced data quality compared to typical X-ray diffractometers.

XRDynamic 500 delivers top-tier resolution (FWHM 0.021° for the initial LaB₆ standard peak) utilizing a standard Bragg-Brentano setup. It also provides an exceptional signal-to-noise ratio, featuring a measurement background reduced by as much as 50 % and negligible parasitic air scattering. The equipment automatically calibrates itself to achieve ideal measurement parameters and dependable outcomes.

Image Credit: Anton Paar GmbH

Image Credit: Anton Paar GmbH

Automated Precision: Daily Convenience

The source pitch concept, protected by a patent and featuring an extra tilt axis, provides automated and accurate adjustment of all optical parts with any X-ray source. Achieve peak primary beam intensity through automatic adjustment with the ideal X-ray source take-off angle suitable for all X-ray mirrors and flat monochromators.

Simple connection of all stages allows for rapid setup modifications, while automated component identification for both optics and stages guarantees the correct instrument setup consistently.

XRDynamic 500 is designed to satisfy both experienced and new users. The XRDdrive control software smoothly integrates simple instrument operation and procedures with the required level of detail, facilitated by automation.

All essential connections for non-ambient experiments are conveniently situated within the diffractometer housing. The availability of an integrated non-ambient control unit (CCU) simplifies the process of using and changing between various non-ambient attachments.

Image Credit: Anton Paar GmbH

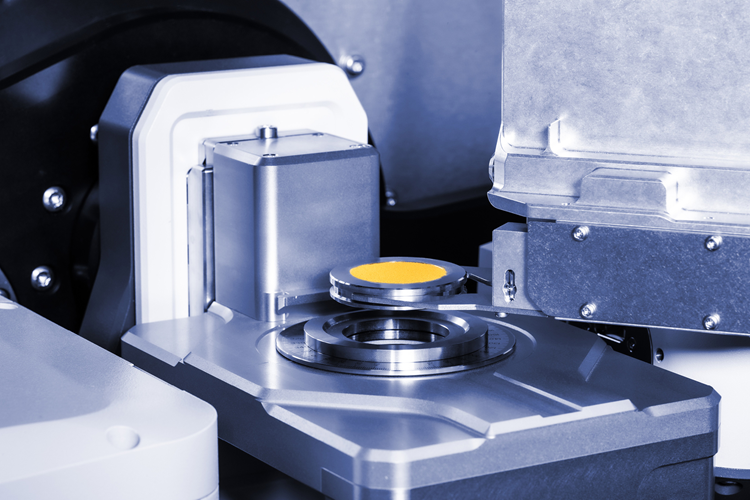

Full Flexibility: For Every Application

The XRDynamic 500 provides extensive measurement adaptability within a unified X-ray diffractometer framework. Regardless of its use for reflection, transmission, or environmental studies, the XRDynamic 500 features sample stages and holders suitable for various scenarios.

Employ adaptable instrument configurations for various applications, utilizing refined solutions for powder XRD, environmental XRD, PDF analysis, and SAXS. Superior components manufactured internally, along with advanced pixel detection technology, establish this instrument as a top-tier product.

Image Credit: Anton Paar GmbH

Renowned Expertise

Customers gain from accredited and skilled assistance on a global scale, featuring individualized customer care that boosts operational availability. Application assistance and professional guidance enable users to attain substantial outcomes rapidly and effectively for all application requirements. The offering extends beyond a mere sale; support is provided throughout the entire product life cycle.

Image Credit: Anton Paar GmbH

Specifications

Source: Anton Paar GmbH

| . |

. |

| X-ray source |

| Source type |

Primux 3000 |

| X-ray generator |

Up to 3 kW |

| Tube voltage / current |

20 kV to 60 kV / 2 mA to 50 mA |

| Goniometer |

| Configuration |

Vertical θ/θ geometry |

| Measurement radius |

360 or 400 mm |

| Maximum usable angular range |

-95 ° to 162.5 ° 2θ |

| Minimum step size |

0.0001 ° |

| 2θ linearity |

≤0.01 ° |

| Maximum angular speed |

15 °/sec |

| Maximum angular resolution |

0.021 ° (FWHM of 1st LaB₆ peak) |

| Sample stages and attachments |

Ambient

sample

stages |

Fixed sample stage

Sample spinner stage (reflection/transmission)

XY stage (with autosampler option)

XRDynamic Autosampler

Capillary spinner stage

EVAC module |

Non-ambient

attachments |

HTK 1200N

HTK 16N/2000N

HTK 1500

TTK 600

XRK 900

CHC plus⁺

BTS 150/500 |

| Detectors |

Solid-state hybrid pixel detectors:

- Pixos 2000 detector (0D and 1D mode)

- Pixos 2000 CdTe detector (0D and 1D mode) for high-energy X-rays

|

| Software |

- XRDdrive: system control and data acquisition software

- XRDanalysis: data processing and analysis software for qualitative and quantitative phase analysis, microstructure analysis, and Rietveld refinement

- XRDview: data plotting and visualization package

- XRDynamic 21 CFR Part 11 package: supporting work in regulated environments and compliance with US FDA 21 CFR Part 11 regulations

|

| General specifications |

Exterior dimensions

(width x depth x height) |

1350 mm x 1160 mm x 1850 mm |

Weight (not including

optional accessories) |

750 kg |

| Power supply |

3-Phase: 3/N/PE AC 400/230 V, 50…60 Hz, 25 A

1-Phase: 208…240 VAC, 50…60 Hz, 36 A |

Maximum power consumption

(without additional controllers for optional equipment) |

5.5 kW |

| Cooling water supply |

Flow rate: > 3.6 L/min, Pressure: 4.5 – 6 bar, Temperature: < 25 °C |

Accessories for XRDynamic 500

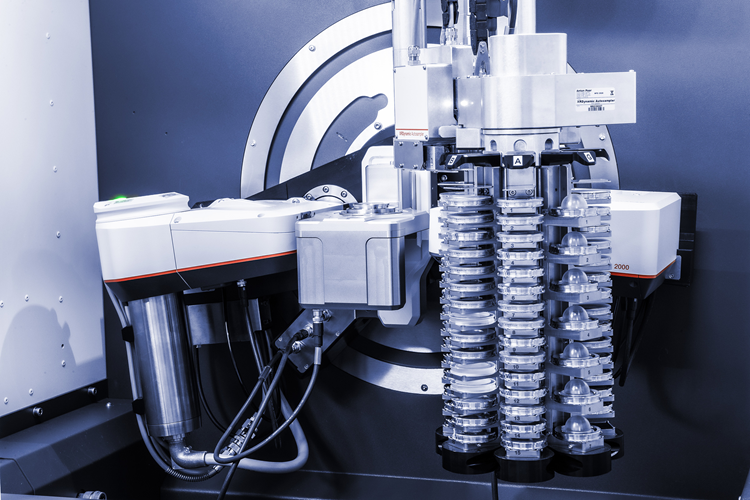

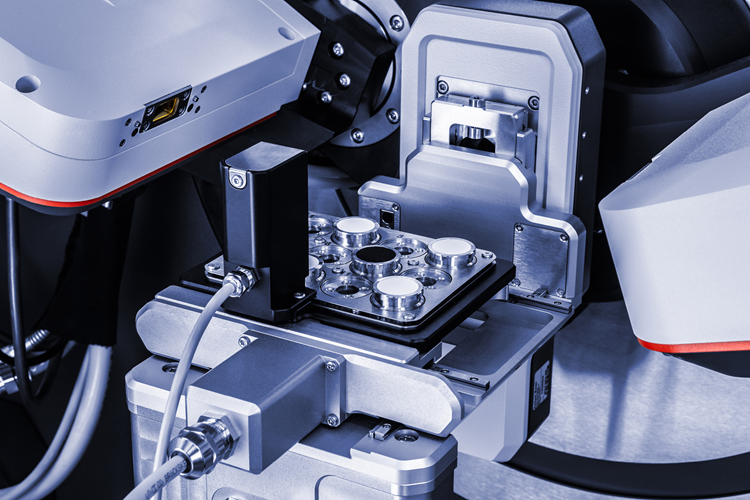

The XRDynamic Autosampler and the XY Stage when used with XRDynamic 500 allow for automated measurements for all sample types, providing reliable results.

Seamless Integration

Error minimization and efficiency maximization benefit customers. The sample changer option for the XY Stage, as well as the XRDynamic Autosampler and its magazines, are fully integrated with XRDdrive software and instantly recognized upon connection. This, combined with the automation level of XRDynamic 500, ensures:

- Plug-and-play setup

- Minimized user intervention

- High throughput with decreased manual handling errors

Image Credit: Anton Paar GmbH

Scalable and Non-Intrusive

The XRDynamic Autosampler mounts easily on any XRDynamic 500 instrument. It is removable and expandable, and it does not interfere with other measurements when not in use.

- Scales from one to seven magazines

- Does not interfere with other measurements

- Quick and precise installation

Image Credit: Anton Paar GmbH

A Portfolio Covering Every Need

The XRDynamic Autosampler complements the XRDynamic 500 sample changer option for the XY Stage, with 3, 6, 12, or 48 sample positions.

This provides users with greater flexibility in choosing a solution for their applications.

Image Credit: Anton Paar GmbH