The MCR 703 MultiDrive is unparalleled in the mechanical analyzer market. It offers dynamic mechanical analysis across various modes, including tension, torsion, bending, and compression.

Its distinctive axial-torsional dynamic mechanical analyzer (DMA) mode facilitates advanced material characterization, such as determining Poisson’s ratio for isotropic materials and analyzing anisotropic material behavior.

The system features air-bearing-based drive units and an optical encoder, which provide exceptional sensitivity in measuring force, torque, and displacement for both soft and rigid materials.

The automatic recognition and alignment of measurement systems and accessories, along with one-handed coupling and touchscreen controls, streamline the setup process and simplify sample preparation. With over 200 accessories available, users can convert the DMA into a comprehensive rheometer, tribometer, UTM Micro, or powder rheometer.

- Determines complex Young’s and shear modulus in one test

- Facilitates quick, easy sample preparation and instrument setup

- Guarantees precise temperature control with high-tech temperature devices

- Combines a full rheometer, tribometer, UTM Micro, and powder rheometer

- Exceeds classic DMA performance in tension, torsion, bending, and compression

Key Features

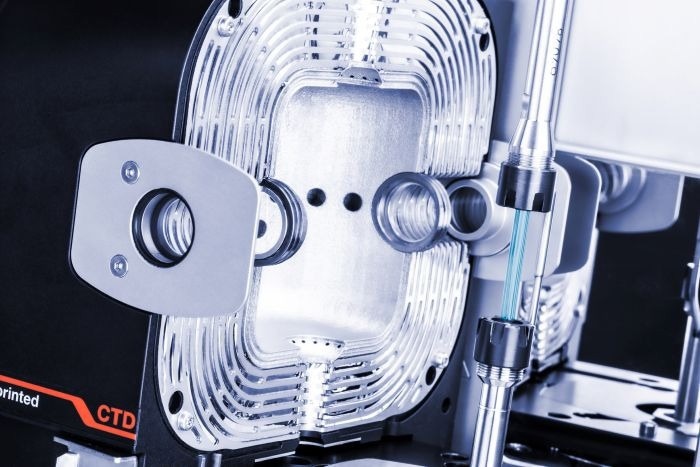

Dynamic Mechanical Analysis Like Never Before

Image Credit: Anton Paar GmbH

The MCR 703 MultiDrive revolutionizes dynamic mechanical analysis (DMA) for liquid, soft, and solid samples, allowing users to conduct DMA in tension, torsion, bending, and compression, as well as thermomechanical analysis (TMA), all with a single instrument.

Users can also perform axial-torsional DMA to ascertain the complex Young’s (E*) and shear (G*) modulus as a function of temperature, frequency, time, or humidity within one experiment. This innovative capability enhances the characterization of anisotropic materials and can determine the Poisson’s ratio of isotropic materials in a single test.

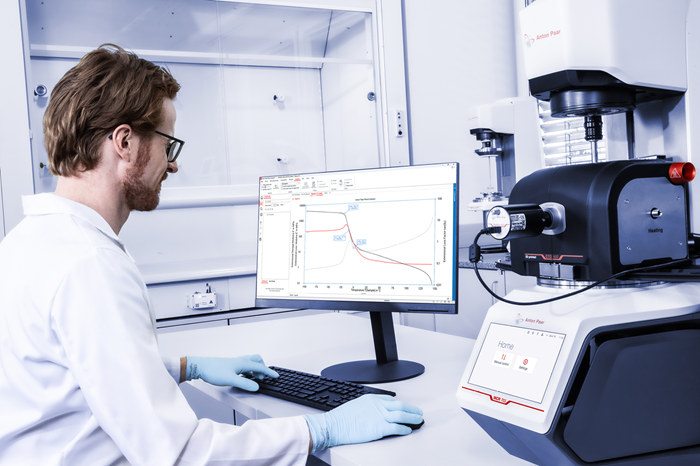

Achieve Unprecedented Measuring Quality

Image Credit: Anton Paar GmbH

The upper rotational and lower linear drives, supported by air bearings, along with optical encoder technology, enable users to conduct linear dynamic mechanical analysis across a force range of 0.5 mN to 40 N, and torsional dynamic mechanical analysis within a torque range of 0.2 nNm to 230 mNm.

Advanced convection temperature devices guarantee uniform temperature distribution from –170 °C to +1,000 °C, providing the precision required for controlling both sample temperature and relative humidity. Each standard measuring system is equipped with an integrated temperature sensor positioned near the clamped sample, ensuring accurate and reproducible measurements directly at the sample.

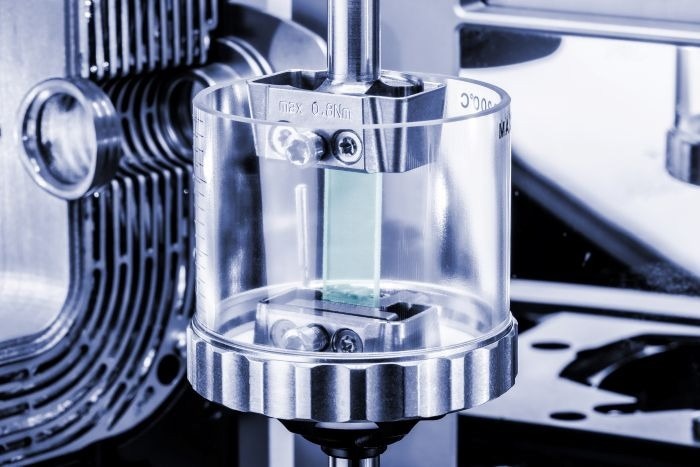

The Smartest DMA, from Start to Finish

Image Credit: Anton Paar GmbH

Users can remove the need to switch back and forth between a PC and the dynamic mechanical analyzer by using the touchscreen for test preparation. QuickConnect facilitates changes to measuring systems in mere seconds with only one hand, while Toolmaster automatically recognizes and configures all accessories.

Fully automated procedures ensure precise and repeatable alignment of measuring systems, removing the need for time-consuming setups and manual adjustments.

The RheoCompass software features wizards and a variety of predefined templates, allowing users to optimize their workflow and easily create the ideal test procedure for specific applications.

More than Just a Dynamic Mechanical Analyzer

Image Credit: Anton Paar GmbH

The advanced hardware and electronics of the MCR 703 MultiDrive position users at the forefront of technology for years, with the flexibility to adapt to various user needs.

The MCR 703 MultiDrive can be transformed into a fully functional rheometer, tribometer, mechanical tester, or powder rheometer with more than 200 application-specific accessories. Beyond traditional dynamic mechanical analysis, it supports comprehensive characterization of liquids, solids, powders, and even mechanical components.

Specialized Solutions, Endless Applications: Explore New Testing Possibilities

Image Credit: Anton Paar GmbH

The MCR 703 Space MultiDrive optimizes workspace to accommodate accessories and complementary measuring instruments. Anton Paar’s in-house development and production team offers devices and accessories designed for a variety of specific applications, including solutions for characterizing solids submerged in liquids.

Shafts can be paired with any disposable or custom geometry. For testing powdery samples, Anton Paar provides material pockets in conjunction with standard DMA measuring systems in bending mode.

Specifications

Source: Anton Paar GmbH

| |

|

| Linear drive for DMA in tension, bending, and compression |

| Maximum force |

40 N |

| Minimum force |

0.0005 N |

| Maximum displacement |

9,400 μm1 |

| Minimum displacement |

0.01 μm |

| Maximum frequency |

100 Hz |

| Minimum frequency |

10-5 Hz |

| Rotational drive for DMA in torsion and rheology |

| Maximum torque |

230 mNm |

| Minimum torque, rotation |

1 nNm |

| Minimum torque, oscillation |

0.2 nNm |

| Angular deflection resolution |

< 1 nrad |

| Maximum angular velocity |

314 rad/s |

| Minimum angular velocity |

0 rad/s2 |

| Maximum frequency |

200 Hz |

| Minimum frequency |

2 x 10-8 Hz |

| Normal force range |

0.001 N to 50 N |

| Temperature control |

| Maximum temperature range |

-170 °C to +1,000 °C3 |

| Maximum heating rate |

60 K/min3 |

| Maximum cooling rate |

30 K/min3 |

| Features |

| DMA in tension, bending and compression |

✓ |

| DMA in torsion |

✓ |

| DMA in combined axial-torsional mode |

✓ |

| DMA in shear and rheology |

✓ |

| Thermomechanical analysis |

✓ |

| Toolmaster, measuring system |

✓ |

| Toolmaster, measuring cell |

✓ |

| QuickConnect for measuring systems (screwless) |

✓ |

| T-Ready |

✓ |

| Low-temperature option, nitrogen evaporation unit |

o |

| Low-temperature option, gas chiller |

o |

| Humidity option |

o |

✓ included | o optional

Trademarks: RheoCompass (9177015), MultiDrive (16731581), T-Ready (9176983), Toolmaster (3623873)

Patents: US Pat. 9574983, 10908058

1 In oscillation, a maximum displacement of ±4,500 μm.

2 In controlled shear stress (CSS) mode. In controlled shear rate (CSR) mode depending on measuring point duration and sampling rate.

3 Limits depend on convection temperature device used and measuring systems. Customized low-temperature option for temperatures down to -170 °C available upon request.