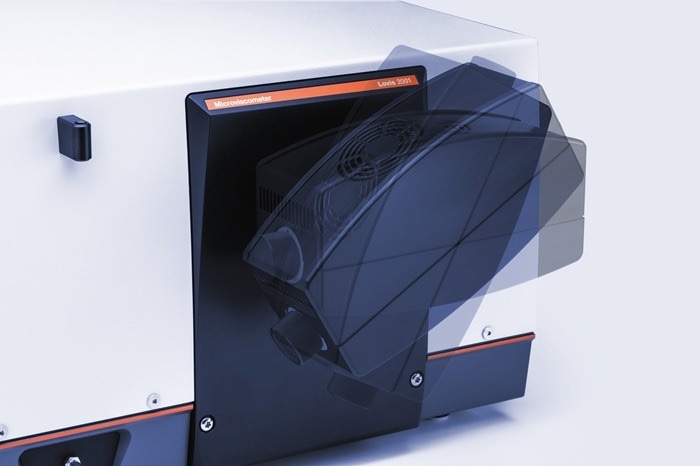

Discover Lovis 2001, a one-of-a-kind rolling-ball microviscometer that operates on Hoeppler's falling ball principle. This falling ball viscometer has an adjustable measurement angle, which ensures pinpoint accuracy, particularly for low-viscosity or shear-sensitive liquids. Furthermore, it provides polymer-specific data such as intrinsic viscosity, K-value, and average molar mass with little sample volume in 30 seconds to three minutes.

The Peltier thermostat provides fast, energy-efficient temperature control (5 °C to 100 °C) for accurate results across a wide range of sample types. An alternative setup expands the temperature range to –40 °C (–40 °F), making it a versatile laboratory choice.

Lovis 2001 Benchtop

Image Credit: Anton Paar GmbH

- Falling ball viscometer with adjustable angle for measuring sample viscosity

- Provides inherent viscosity, K-value, average molar mass, and more

- Referenced in US Pharmacopoeia chapter 913 and Ph. Eur. 2.2.49

- Automated filling and cleaning through sample changer

- Integrate to measure refractive index and pH in one step

Lovis 2001 Module

Image Credit: Anton Paar GmbH

- Combination with the DMA density meter

- Dynamic and kinematic viscosity in a single measurement cycle

- Referenced in US Pharmacopoeia chapter 913 and Ph. Eur. 2.2.49

- Wort: MEBAK- (R-205.10.282) and ASBC- (Wort-13B) compliant

- Optional pH, refractive index, and sample changer

Key Features

A Falling Ball Viscometer with Adjustable Inclination Angle for Maximum Precision

Image Credit: Anton Paar GmbH

The moving capillary block provides the maximum measurement precision by covering an angle range of 15° to 80° in either direction. With speed tailored to the type of sample, the rolling ball does not produce a turbulent flow in low-viscous liquids like fast-falling balls do in conventional falling ball viscometers.

Lovis 2001 additionally shows the shear rate and lets the user test shear-sensitive samples. The instrument can measure dynamic viscosity from 0.2 mPa·s to 10,000 mPa·s, making it suitable for many applications without requiring several systems. It employs electromagnetic detection and is thus unaffected by sample opacity and turbidity.

Combine for a Superior Measurement System

Image Credit: Anton Paar GmbH

Take advantage of modularity for a smooth and efficient measurement process. Lovis 2001 monitors runtime, relative viscosity, and intrinsic viscosity while instantaneously calculating dynamic viscosity and kinematic viscosity based on density input. An autosampler enables our innovative falling ball viscometer to measure the sample in time-saving flow-through mode without requiring operator intervention.

Upgrade to include new measuring units, such as density, refractive index, or pH, which can be calculated in the same measuring cycle with no further effort. The AP Connect lab execution software enables streamlined and consolidated data management.

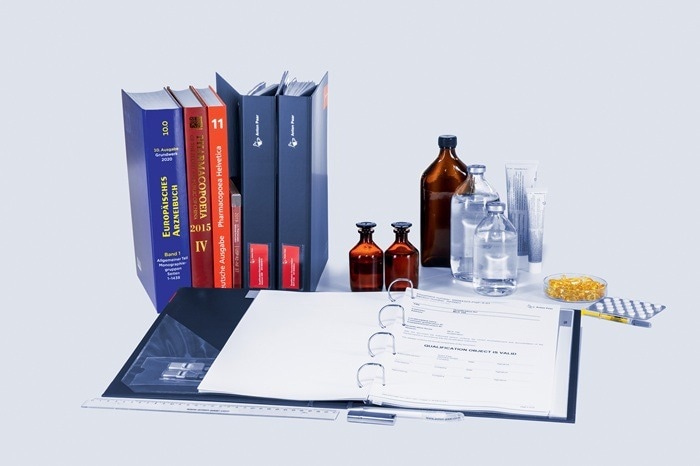

Full Compliance with Industry Standards

Image Credit: Anton Paar GmbH

Lovis 2001 complies with all 21 CFR Part 11 criteria and provides 100% data integrity. Measure according to US Pharmacopeia Chapter 913 and Ph. Eur. 2.2.49. Use the acclaimed DMA density meter to measure relative density (Ph. Eur. 2.2.5) and specific gravity (<841>).

With the optional AISQ+ documentation for regulated industries, users can complete instrument qualification and validation in a single day. Together with a density meter, Lovis 2001 measures wort in accordance with ASBC and MEBAK standards.

Falling Ball Viscometer with Integrated Polymer Software

Image Credit: Anton Paar GmbH

The adjustable falling ball viscometer's integrated software computes and presents many metrics for polymers, including K-value, average molar mass, relative viscosity, specific viscosity, decreased viscosity, inherent viscosity, and intrinsic viscosity. Automating polymer analysis in this manner eliminates the use of external instruments, which are prone to errors. The results are saved in a database so they can be compared later.

Measure Aggressive Chemicals without Risk

Image Credit: Anton Paar GmbH

The hermetically closed system shields delicate samples from contamination and makes it easy for users to test volatile or hazardous materials. The break-proof PCTFE capillaries with a gold-coated ball and FFKM O-rings allow users to test compounds as harsh as hydrofluoric acid, even though the borosilicate glass capillaries are appropriate for the majority of solvents and acids.

Using short capillaries with sample volumes as low as 100 μl minimizes waste and lowers operating costs for valuable or limited sample amounts. Recovering the sample for additional testing after measurement can decrease the total cost of investigations.

Technical Specifications

Source: Anton Paar GmbH

| |

Lovis 2001 |

Lovis 2001 Module + DMA density meter |

| MEASURING RANGE |

|

|

| Dynamic viscosity |

0.2 mPa·s to 10,000 mPa·s |

| Shear rate |

0.5 s-1 to 1000 s-1 |

| Temperature |

5 °C to 100 °C (41 °F to 212 °F)

-40 °C to 100 °C (-40 °F to 212 °F) (with counter cooling)1) |

| Density |

- |

0 g/cm³ to 3 g/cm³ |

| Temperature: Density |

- |

0 °C to 100 °C (32 °F to 212 °F) |

| PRECISION |

|

|

| Viscosity: Repeatability s.d. |

0.1 % 2) |

| Viscosity: Accuracy |

0.5 % 3) |

| Measuring time: Resolution |

0.001 s |

| Measuring time: Accuracy |

0.05 % |

| Temperature: Repeatability s.d. |

0.005 °C |

| Temperature: Accuracy |

0.02 °C |

| Inclination: Repeatability s.d. |

0.02 ° |

| Inclination: Accuracy |

0.1 ° |

| FURTHER SPECIFICATIONS |

|

|

| Test duration |

Minimal 30 s, typical 3 min |

| Sample volume |

0.1 mL to 0.8 mL |

1 mL to 3 mL |

| Weight |

19.9 kg (43.9 lb) |

29.3 kg (64.6 lb) |

| Dimensions (L x W x H) |

526 mm x 420 mm x 230 mm (20.7 in x 17.2 in x 9 in) |

| Power supply |

AC 100 V to 240 V; 50 Hz to 60 Hz; 190 VA |

| Trademarks |

DMA (013414867), Xsample (013856059), Abbemat (1084545) |

1) Specified temperatures are valid for a max. ambient temperature of 35 °C (95 °F). Lower measuring temperatures are achieved in lower ambient temperatures and/or with special equipment.

2) Verified with a 1.59 capillary at 70° angle and Ethanol 96 % at 20 °C using the same ball for all repeated measurements.

3) Verified with a 1.59 capillary with a single-point adjustment performed on site at 70° angle; adjustment and all measurements performed with distilled water at 20 °C with the same ball.