The ability to simulate patterns based on the physics of electron dynamical diffraction is one way that the EDAX OIM Matrix™ software improves electron backscatter diffraction (EBSD) analysis. Compared to conventional kinematic diffraction-based methods, this optional module for EDAX OIM Analysis™ generates more realistic pattern simulations and more correctly captures electron interaction behaviors inside a material.

To increase indexing performance and orientation precision, these generated patterns can be used easily and precisely compared with EBSD patterns that have been acquired experimentally.

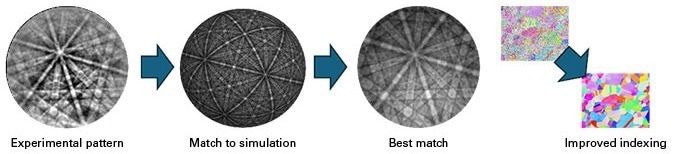

Figure 1. Schematic of spherical indexing procedure where experimental EBSD patterns are projected onto a sphere to match against a simulated master pattern to improve indexing performance. Image Credit: Gatan, Inc.

Spherical Indexing

The latest EDAX spherical indexing method uses master pattern simulations to index experimentally obtained EBSD patterns, yielding better results.

- Enhances indexing efficacy in contrast to conventional Hough-based indexing

- Accelerates reindexing to >10,000 pps

- Improves the signal-to-noise ratios of EBSD patterns when used with NPAR™

- The integration of OIM Analysis facilitates easier access to the spherical indexing functionality

- Appropriate for transmission Kikuchi diffraction (TKD) to improve spatial resolution

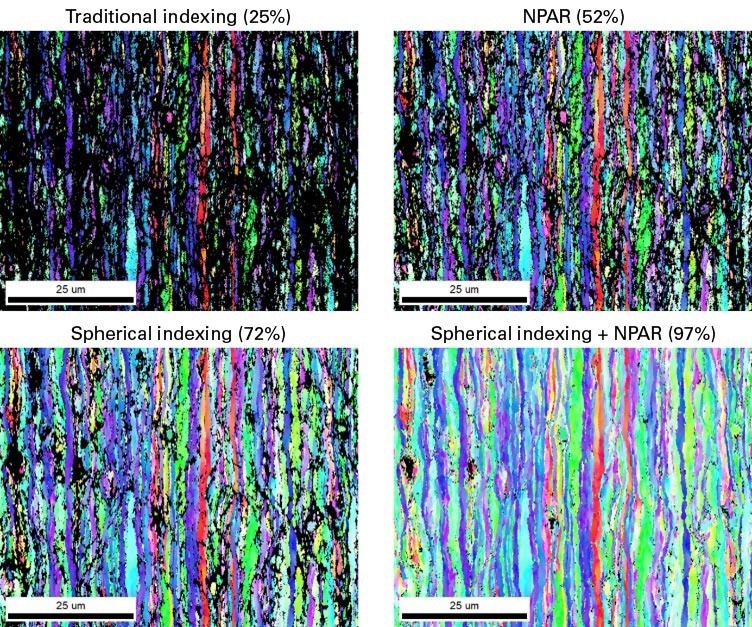

Figure 2. Comparison of spherical indexing performance with traditional Hough-based indexing and NPAR approaches on a deformed aluminum alloy. The indexing success rates (shown in parentheses) are maximized by combining spherical indexing and NPAR together to analyze as much of the field of view as possible. Image Credit: Gatan, Inc.

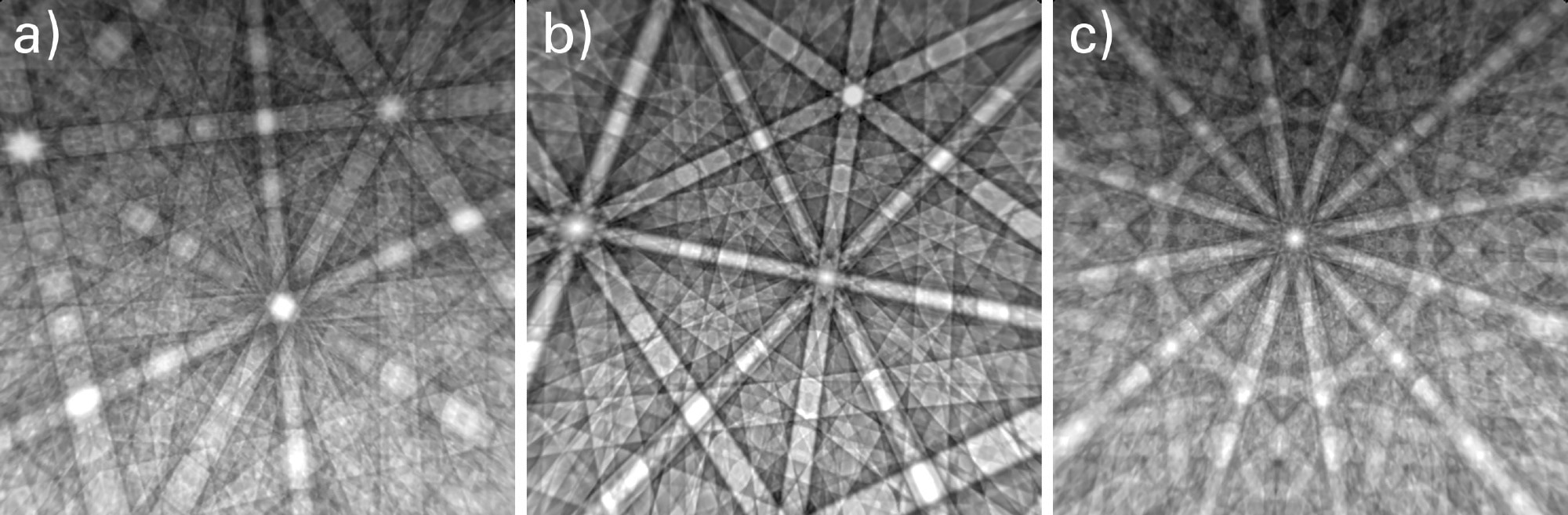

Figure 3. Dynamically simulated EBSD patterns for: a) Cr23C6, b) TiN, and c) Sigma phases using OIM Matrix. Image Credit: Gatan, Inc.

Realistic EBSD Pattern Simulations

- Dynamic diffraction effects and forward modeling are used to properly forecast scattering and diffraction intensities in EBSD patterns

- Easily compares experimental patterns to dynamic simulations

- With over 280 calculated master patterns at their fingertips, users can start simulations right away

- Additional crystals are simulated based on crystal structure and atomic position information

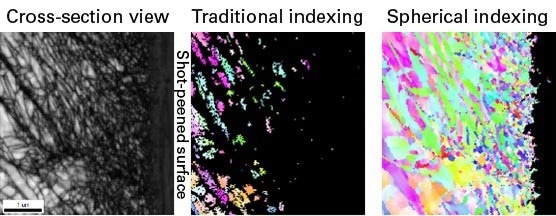

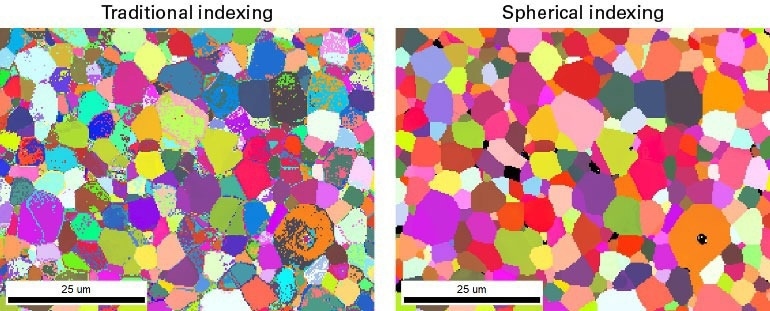

Figure 4. Spherical indexing improvements on a shot-peened titanium alloy. The increased colored orientation measurements and reduction of black non-indexed points with spherical indexing compared to traditional indexing shows where orientations can now be reliably measured. Image Credit: Mr. Prathompoom Newyawong, NSTDA Characterization and Testing Service Center

Dictionary Indexing

- Compared to conventional Hough-based indexing, template matching performs better

Orientation Refinement

- Increases the accuracy of orientation when characterizing deformed materials

- Reaches resolution precision levels of less than 0.01°

- Resolves pseudosymmetry indexing artifacts

Automatic Structure File Optimization

- Generates and improves the reflector list automatically for traditional Triplet Indexing

- Simplifies the process of analyzing new materials

Figure 5. Improved indexing and grain determination in the NMC Li-ion battery cathode material. The speckling within grains with traditional indexing is eliminated with spherical indexing. Data courtesy of Dr Siyan Wang, Imperial College London. Image Credit: Gatan, Inc.