The TMC pneumatic vibration isolation systems are ideal for tool designers wanting excellent vibration isolation of ultra-precision instruments. TMC is now offering the company’s industry standard MaxDamp®, Gimbal Piston™, and UltraDamp™ isolators in a convenient range of damping levels, capacities, and leveling versions to match numerous applications.

The systems are ideal for OEM applications. These isolators are offered in a modular, interchangeable, and upgradable design. To ensure customers specify a version that will meet their settling time and isolation needs, TMC engineers can model customer’s configuration with their "Moving Stage Application Model."

The TMC Advantage

- Built specifically for OEM applications

- Provides a high level of vibration attenuation, even in quiet environments

- Supporting payloads ranging from 90 kg to 8,200 kg (200 to 18,000 lb.)

- Multiple versions of height control

- Multiple levels of damping to choose from

- Isolator designs are interchangeable. Easily facilitates changes of requirements without expensive tool redesign

Features

Four capacities:

- 160 kg (350 lb.) @ 5.50 kPa (80 PSI)

- 450 kg (1000 lb.) @ 5.50 kPa (80 PSI)

- 1150 kg (2500 lb.) @ 5.50 kPa (80 PSI)

- 2600 kg (5700 lb.) @ 5.50 kPa (80 PSI)

Three damping levels:

- Gimbal Piston™ for maximum vibration attenuation

- UltraDamp™ for maximum damping of resonance

- MaxDamp® for high damping of resonance

Three leveling options:

- Standard height control (+/- 2.5 mm, +/- 0.1”)

- PEPS® II Non-contact – Precision Electronic Positioning System (+/- 0.0025 mm, +/- 0.0001”)

- Precision height control Valves (+/- 0.25 mm, +/- 0.01”)

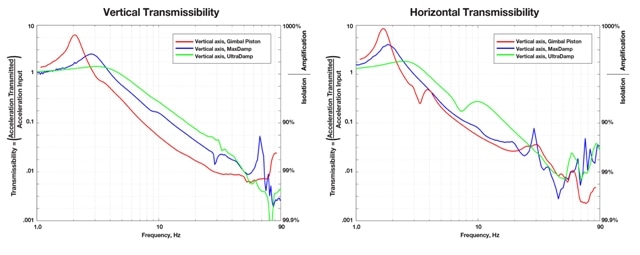

Performance

Three damping levels. Select maximum vibration attenuation or aggressive damping for applications with robotic motion or moving stages.

Choose between three damping levels