ACOMP is an automated smart manufacturing system that continually analyzes polymers during production, providing real-time data on reaction kinetics and polymer parameters such as residual monomer, monomer conversion, polymer composition, molecular weight, and intrinsic viscosity.

This automated monitoring solution enables tighter process control, increasing polymer yields, quality, and consistency, improved worker safety, shorter cycle times, lower VOCs, and lower energy and raw material consumption. ACOMP allows users to observe polymerizations in real-time and allows them to manage certain desired polymer characteristics.

Access the Lab ACOMP Advantage

- Improved polymer output, quality, and consistency

- Enhance process control

- Cut down on material use, VOCs, and cycle times

- Detect irregularities during production

24/7 Smart Manufacturing

During the fracking boom, there was a significant demand for various improved oil recovery chemicals, and many producers looked for ways to expand capacity using existing assets. Nalco, an Ecolab Company, collaborated with Yokogawa Fluence Analytics to pioneer the usage of ACOMP in one of its manufacturing facilities and then used the smart manufacturing system's real-time data streams to cut batch cycle times by 17%.

Common ACOMP Applications

ACOMP has been utilized in a variety of polymerization applications, showcasing significant value in areas such as elastomers, adhesives, paints and coatings, and numerous water-soluble polymers.

- Adhesives

- Elastomers

- Paints and coatings

- Water-soluble polymers

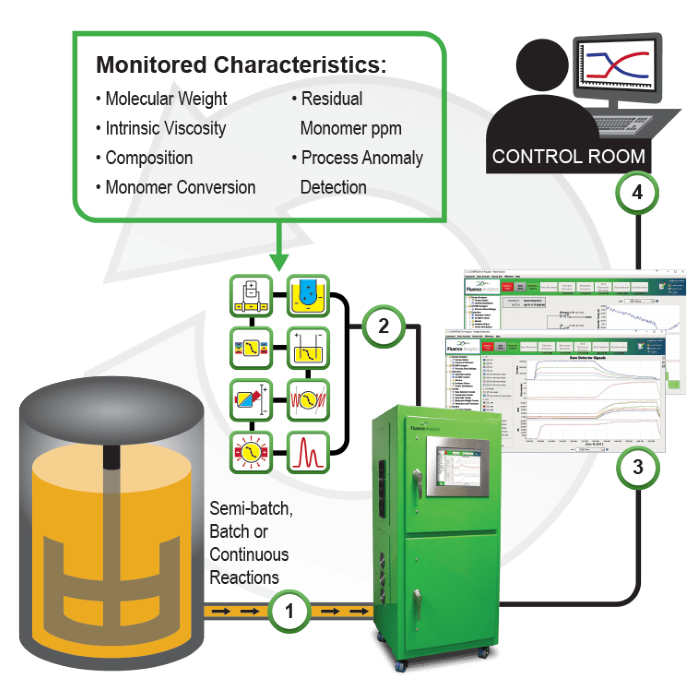

How ACOMP Works

Image Credit: Yokogawa Fluence Analytics

- Polymer is removed continuously from the reactor

- Automated real-time measurements are conducted with many sensors

- Proprietary analysis techniques provide important parameters for optimization

- This enables optimized process control, plant digitization, shorter cycle times, higher yields, and consistency

Smart Technology

ACOMP is a smart manufacturing device that can assist polymer producers with digital transformation initiatives. The system consists of dozens of smart sensors and a detector train, allowing for real-time characterization of numerous polymerization processes.

ACOMP detectors include ultraviolet/visible absorption (UV/Vis), differential refractive index (DRI), dilute solution single capillary viscometer (Visc), multi-angle light scattering (MALS), and others.

ACOMP Animated Explainer Video - Polymer Optimization

Video Credit: Yokogawa Fluence Analytics