The NEG'ATOR constant force spring is the simplest and adaptable form of constant force extension spring.

It is a prestressed flat strip of spring material formed into almost constant radius coils around itself or on a drum. When deflected, the spring material straightens as it exits the drum. This straightened length of spring stores energy by assuming its natural radius.

The Material

For high-grade force springs. Hunter Spring provides constant force springs constructed of 301 High Yield Stainless Steel. Other materials, such as Elgiloy, Inconel, or high-carbon steel, are available on request for bespoke applications.

Key Features

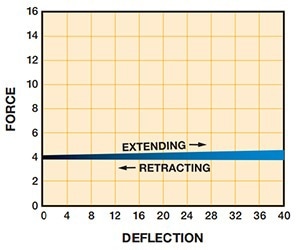

- Low force gradient over the full deflection range

- Extremely lengthy linear extensions are feasible

- Maximum force generated at initial deflection

- Allows for reduced package sizes due to its natural compact size and light weight

- A range of materials can be used

- Negative force or torque gradient is feasible

Standard or Custom Springs

Hunter Spring can offer standard or customized constant force spring designs.

- Fatigue Life 20,000 Cycles Minimum

- Fatigue Life 13,000 Cycles Minimum

- Fatigue Life 2,500 Cycles Minimum

Constant force springs can also be designed to provide a negative force or torque gradient. For applications with limited space, springs can be coiled together in a laminated arrangement to increase output force while minimizing spring size and fatigue life.

Use the constant force spring design worksheet to indicate the requirements, and the Application Engineers will supply users with a design that meets their demands.

Image Credit: Hunter Spring