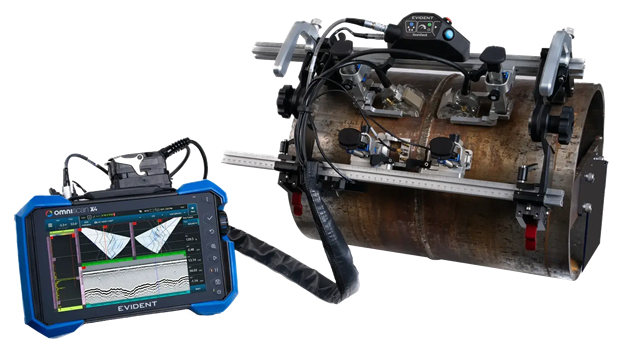

The HSMT-Flex™ scanner is intended for manual, encoded examination of circumferential welds on pipes with outer diameters of 114.3 mm (4.5 inches) and larger, able to accomodate up to eight probes.

The scanner comes in standard and high-temperature configurations and may be paired with a ScanDeck™ module. Its modular design enables rapid reconfiguration with tool-free mechanisms.

Overview

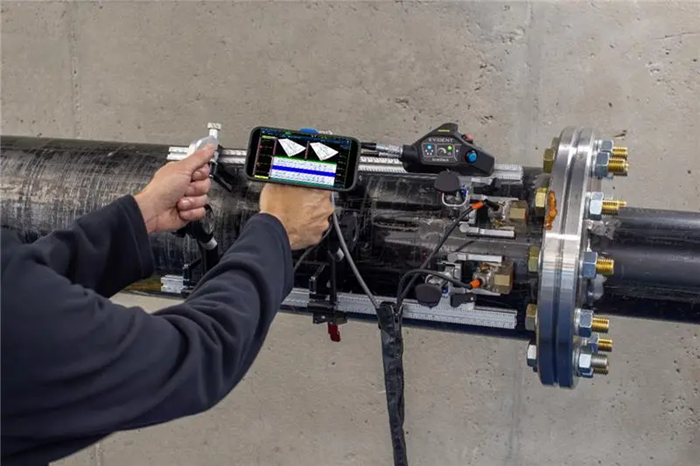

Smarter, More Adaptable Circumferential Weld Inspection

Image Credit: Evident Corporation

The HSMT-Flex scanner enhances encoded girth weld ultrasonic inspection by reducing risk of rescans, simplifying the overall setup, and ensuring high-quality data gathering. This allows users to operate more efficiently and more confidently in challenging settings.

The HSMT-Flex scanner connects to the surface using magnetic wheels and can check pipe exterior diameters ranging from 114 mm (4.5 inches) to smooth surfaces. Its folding mechanism guarantees that all spring-loaded probe holders maintain a constant, perpendicular contact pressure on the examination surface.

Now available in a high-temperature form, the scanner is able to perform inspections on hot surfaces, reducing downtime and ensuring asset integrity.

Features

Ensure Data Quality and Reduce Rescans

Image Credit: Evident Corporation

- Real-time monitoring and alerts: The optional ScanDec module can be used to start acquisition on the OmniScan™ flaw detector remotely. It also analyzes probe connection and warns of high scanning speeds, reducing data loss and improving inspection reliability.

- Integrated laser guide: The laser guide built within the ScanDeck module allows for perfect scan alignment, ensuring excellent weld coverage.

- Optional smartphone integration: The OmniScan X4 RCS app can monitor scan data in real time, streamlining workflow, and allowing users to maintain focus on scanning.

Work Continuously with Fewer Interruptions

Image Credit: Evident Corporation

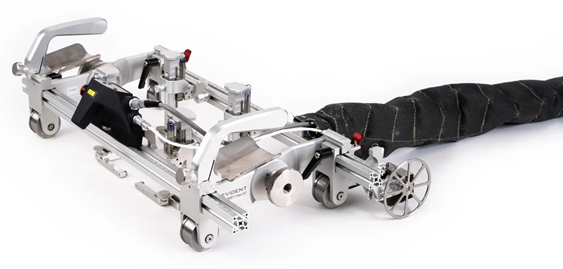

- Integrated braking system: This system locks the scanner in position to prevent slippage when pausing or adjusting the instrument, ensuring data integrity.

- Streamlined cable management: A zippered sleeve secures and protects cables, resulting in a cleaner, safer inspection environment and fewer cable-related disruptions.

- Improved wear-resistant wheels: Durable magnetic rubber wheels with pliant covers provide smooth rolling and strong pipe adhesion, resulting in great data quality and less required maintenance.

Adapt Quickly to Varying Weld Types and Pipe Geometries

Image Credit: Evident Corporation

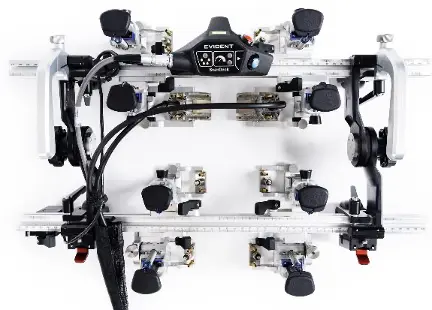

- Toolless adjustments: Easily adjust probe holders, frame, encoder, umbilical mount, ScanDeck module, and cable sleeve without tools. The vertical latching configuration allows users to swap wedges and probes swiftly.

- Configurable probe mounting: Mounting probes inside and outside the frame allows for the scanning of complicated geometries, such as pipe-to-component configurations.

- Choice of different frame bar lengths: Expand to accommodate up to eight probes (PA and TOFD) with greater PCS for thick-wall parts, or reduce to meet tight inspection regions.

High-Temperature Model

Minimize Downtime with Safer, Reliable Hot-Surface Scanning

Image Credit: Evident Corporation

The HSMT-Flex HT scanner can continuously inspect surfaces up to 350 °C (662 °F)*. Analysis can be performed before shutdowns are complete, allowing for earlier defect detection and more effective maintenance planning.

- Heat-Resistant Components: Metal wheels can endure direct contact with hot surfaces, and all other parts are radiation-resistant, allowing for safe operation in high-temperature conditions.

- Operational Efficiency: Inspect hot pipes, tanks, or pressure vessels without waiting for them to cool down completely, to spot problems early and prevent unnecessary downtime.

* Continuous scanning up to 300 °C (572 °F) with the ScanDeck module. Cables and sleeves can withstand short-term contact with hot surfaces.