eralab OCM is a comprehensive oil analysis platform designed to empower companies with predictive and proactive maintenance.

By delivering crucial insights into equipment health and lubricant condition, it analyzes and evaluates three key areas: contamination, wear, and oil composition. Implementing eralab OCM leads to reduced costly downtime and lubricant changes, while significantly extending the operational life of machinery.

The Key to Machine Health

Image Credit: eralytics GmbH

The operational integrity and durability of any machine depend on adequate lubrication. To verify that the oil continues to meet performance standards, several key oil condition categories must be monitored. These include:

Contamination

Quantifies particles and their source (water, fuel, or other impurities) impacting oil quality.

Wear

Analyzes metallic debris to detect early signs of component degradation in gearboxes, bearings, pistons, and other parts.

Oil Composition

This system provides comprehensive oil analysis, detecting even subtle changes in composition, including those in visually clean oil. It monitors key parameters, such as viscosity, acidity, oxidation, and additive levels, to accurately assess the health of the oil and overall operational conditions.

Modifications within these categories empower maintenance teams to spot initial problems, intervene promptly, and avert significant damage or unscheduled downtime.

eralab OCM Pro

Image Credit: eralytics GmbH

Image Credit: eralytics GmbH

The eralab OCM Pro delivers a comprehensive Oil Condition Monitoring (OCM) solution, encompassing the monitoring of three vital categories: contamination, wear, and oil composition.

This system is specifically engineered to furnish clear responses to crucial inquiries such as:

- Is the oil wet?

- Is any part of my machine starting to fail based on the wear metals found?

- Are there any signs of wrong operation conditions?

- Has the oil composition changed?

- What is the chemistry of wear and contamination?

- Was the appropriate oil used for refilling?

- Is the oil clean enough for operation?

The erasoft OCM receives data from four simple measurements. It then analyzes the results, activating alarms and warnings based on the oil's condition, and provides a report on its health, including recommended maintenance actions for the maintenance team.

eralab OCM Pro's comprehensive oil analysis minimizes unplanned downtime, lengthens oil drain intervals, maximizes machine lifespan, and optimizes local maintenance strategies.

eralab OCM Pro combines eraSoft OCM with the following analyzers for complete oil condition monitoring: eraSpec Oil, eraOil, eraVisc X, and eraCount XS.

Download the Brochure for More Information

eralab OCM Basic

Image Credit: eralytics GmbH

Image Credit: eralytics GmbH

eralab OCM Basic offers a focused OCM solution, concentrating on two key oil condition categories: contamination and oil composition. This package is ideal for applications where wear monitoring is not a primary requirement.

eralab OCM Basic is designed to provide straightforward answers to critical questions, including:

- Is the oil wet?

- Was the appropriate oil used for refilling?

- Is the oil clean enough for operation?

- Are there any signs of wrong operation conditions?

- Has the composition of the oil changed?

The eralab OCM Basic, much like its Pro counterpart, simplifies oil health analysis. It requires only three basic measurements to generate a report with all pertinent results and maintenance recommendations. This makes it the perfect starting point for oil condition monitoring, providing the necessary tools to avoid unplanned downtime and extend drain intervals.

eralab OCM Basic combines erasoft OCM with eraspec oil, eravisc X, and eracount xs analyzers.

eralab OCM: The All-In-One Partner for Oil Condition Monitoring

Image Credit: eralytics GmbH

For anyone involved in OCM – whether a beginner, outsourcing, or an expert – eralab OCM offers a flexible, comprehensive solution with unparalleled reliability, transparency, and control.

- Easy to use for beginners: eralab OCM analyzers streamline each phase and allow the user to obtain actionable, results-driven insights within minutes. All of this is achieved with ease and simplicity.

- Effortless switch to in-house testing: Implement it today and take charge tomorrow with the reliable analyzers that allow the user to integrate oil analysis into operations, enabling the user to proactively make informed decisions instead of just passively receiving data. It is quick and straightforward.

- Next level OCM testing professionals: With eralab OCM, users can enhance the OCM practice to unprecedented levels – showcasing more efficient workflows, accurate diagnoses, and seamless integrations. This represents a groundbreaking advancement for experienced users.

- Maximum flexibility: Improve the eralab OCM Basic by incorporating eratest ferro for rapid ferrous debris assessments, utilizing eraflash X for fuel dilution analysis, or by integrating third-party analyzers to broaden its functionalities. The adaptable configurations guarantee that the eralab OCM operates according to the user’s preferences.

- Lab-grade accuracy. All eralab OCM analyzers are manufactured by eralytics and are recognized for their accuracy and dependability.

Download the Brochure for More Information

Software Solution erasoft OCM

Image Credit: eralytics GmbH

Image Credit: eralytics GmbH

Image Credit: eralytics GmbH

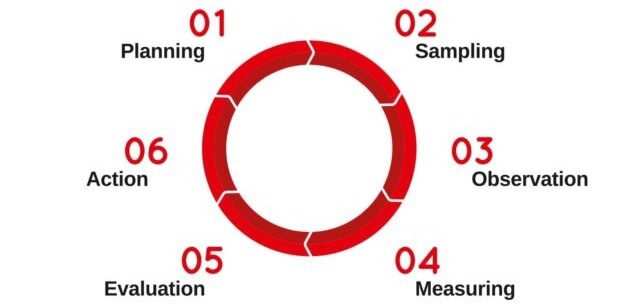

erasoft OCM serves as the fundamental software for eralab OCM. It comprehensively addresses and digitizes each phase of the OCM process, encompassing asset management, sampling planning, data analysis, action tracking, and maintenance recommendations. The software produces clear reports that emphasize warnings and errors while offering maintenance suggestions based on the test outcomes.

Tailored to meet the specific needs of customers, the package can be adaptively configured to align with both technical specifications and budgetary constraints.

eralab OCM Analyzers

Source: eralytics GmbH

| Category |

Parameter |

eraoil |

eracount xs |

eravisc X |

eraspec oil |

|

|

ASTM

D6595 |

ISO

4406 |

ASTM

D445 corr. |

ASTM

E2412 |

| Contamination |

Particle count ISO codes |

|

x |

|

|

|

Boron, Calcium, Sodium, Lithium, Potassium, Silicon |

x |

|

|

|

|

Water |

|

|

|

x |

| Wear |

Copper, Silver, Chromium, Titanium, Aluminum, Magnesium, Nickel, Iron, Manganese, Lead, Tin, Molybdenum, Cadmium, Vanadium |

x |

|

|

|

| Composition |

Viscosity 40 °C & 100 °C & VI |

|

|

x |

|

|

Total Acid Number (TAN) |

|

|

|

x |

|

Total Base Number (TBN) |

|

|

|

x |

|

Oxidation, Nitration |

|

|

|

x |

|

Additives (Phenol, Amine, Antiwear, etc.) |

|

|

|

x |

|

Boron, Magnesium, Calcium, Barium, Zinc, Molybdenum, Phosphorus |

x |

|

|

|

eralab OCM: Features at a Glance

eralab OCM provides a selection of user-friendly, robust, and precise oil analyzers. These analyzers, combined with the sophisticated erasoft OCM software solution, enable the creation of an effective in-house oil condition monitoring program.

The eralab OCM analyzer portfolio ensures that eralytics has a suitable solution for all phases of in-house oil condition monitoring.

Download the Brochure for More Information