TIDAS, the automated Hegman gauge analyser objectively measures particle size in dispersions. The system uses analysis software in conjunction with light scattering techniques to objectively identify outcomes.

A Revolution for Particle Size Analysis

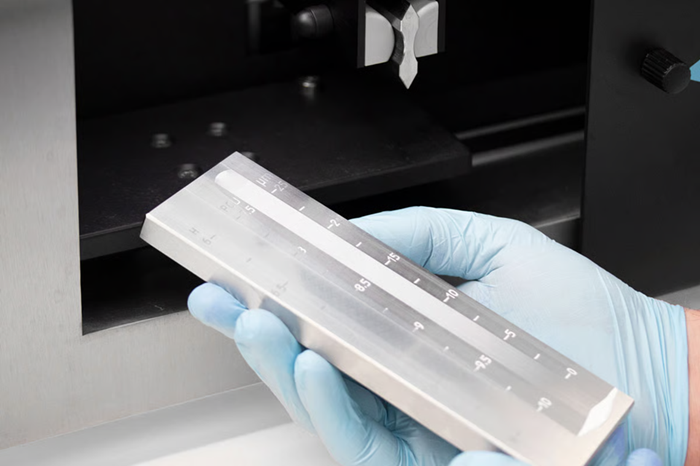

TIDAS eliminates operator variation and ensures reproducibility by automating the analysis of a Hegman gauge to evaluate the fineness of grind, objectively. Less than 20 seconds are needed for each reading. TIDAS will benefit users if they use a Hegman gauge in their processes.

Objective Rating in Seconds

Image Credit: Labman

A traditional Hegman test is completely subjective and susceptible to human error. TIDAS collects a raw image of the dispersion, which is then digitally analyzed. The precise amount of particles per micron slice is tallied to produce an objective and reproducible reading.

- Have confidence in just one reading

- Less than 20 seconds required for each reading

Eliminate Costly Over-Production

Image Credit: Labman

The coatings industry produces many products that start out as pigment or powder. These raw materials must be ground down to standard, which requires expensive manufacturing procedures. Achieving even minor particle size reductions can take a very long time. Even minor mistakes made by people might result in significant expenses due to needless overprocessing. Figuring out the ideal grinding time removes this risk.

- Establish the ideal processing duration for powders and pigments

- Reduce excessive processing expenses without sacrificing quality

- Release factory equipment so that other tasks can be completed

Analyze All Colors and Finishes

Image Credit: Labman

TIDAS works with a wide range of products, including paints, resins, inks, adhesives, battery materials, food products, and cosmetics. The TIDAS program is intended to remove dust, bubbles, and foam from the dispersion. It can also take accurate readings from clear and metallic materials, which are notoriously difficult to rate by eye due to the dark field illumination technique used to capture the image.

- Robustly analyze transparent and metallic materials

- Compatible with any liquid sample, making it an essential quality control tool for numerous sectors

Applicable to Many Applications

Polymers, cosmetics, food, ceramics, solder pastes, additives, minerals, clear and metallic liquids, battery materials, paints, pigments, inks, resins, sealants, graphene, and much more.

Tried and Tested

TIDAS was created over 25 years ago and has undergone numerous modifications, improving its performance and dependability. It serves over 40 countries and is used by various companies, including Akzo Nobel, Venator, and BASF.

Comply to Industry Standards

TIDAS regulates testing to increase conformity with industry standards ISO 1524, GB/T1724, ASTM D1210, D1316, D1084, D3333, EN 21524, and JIS K 5600-2-5.

How Does TIDAS Work?

TIDAS, with its sophisticated but simple design, employs a variety of technologies to consistently give the most precise results.

Precise Image Capture: Produce super-sharp images with a line scan camera

Image Credit: Labman

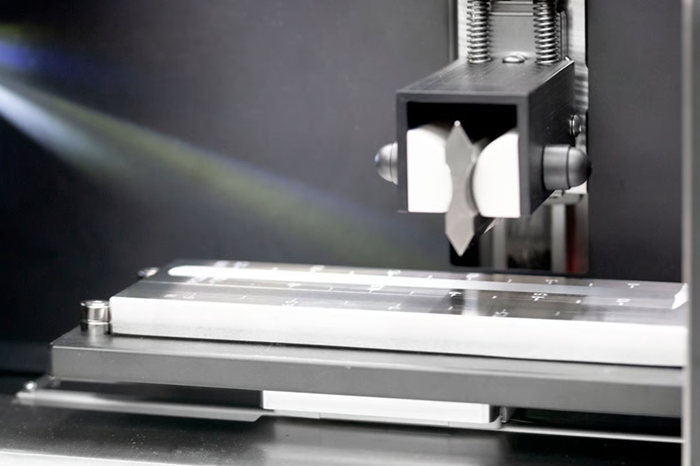

The system includes a high-definition line scan camera, which aids in the creation of distortion-free images. After the Hegman gauge is automatically drawn down, the device casts a light beam onto the dispersion, allowing the image to be taken.

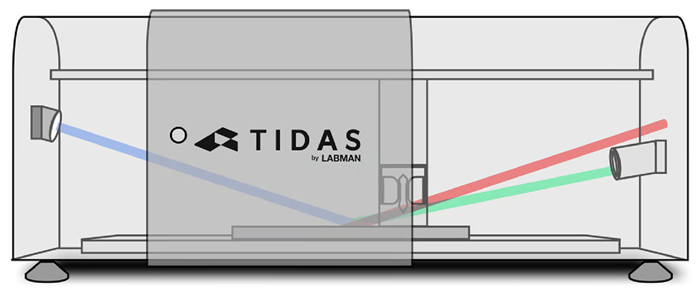

Dark Field Illumination: Intelligent technology highlights particles that people want rather than those they do not.

Image Credit: Labman

To obtain an image of the Hegman gauge surface, the dark field illumination technique is utilized. This duplicates the manual inspection procedure stated in ASTM D 1510 and ISO 1524.

This technique involves directing a low-angle beam of light (seen in blue) onto the gauge surface. When there are no particles on the flat surface, this reflects at the same angle. When particles become visible, light scatters and is detected by the camera (seen in green). This produces a highly contrasted image.

The TIDAS software is also intended to remove artifacts like dust, bubbles, and foam from the dispersion, resulting in a clean and accurate analysis.

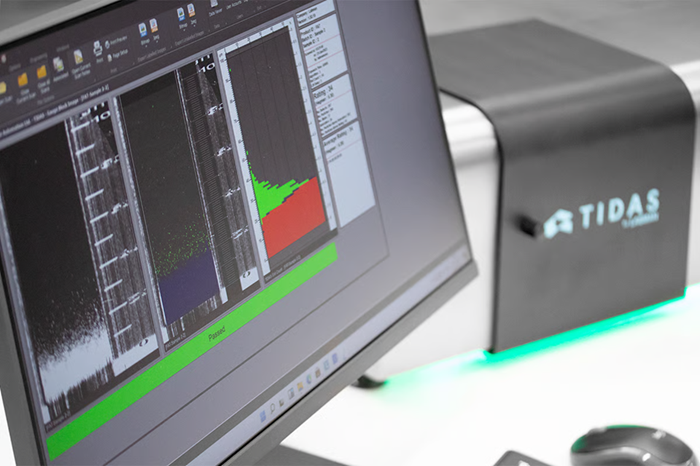

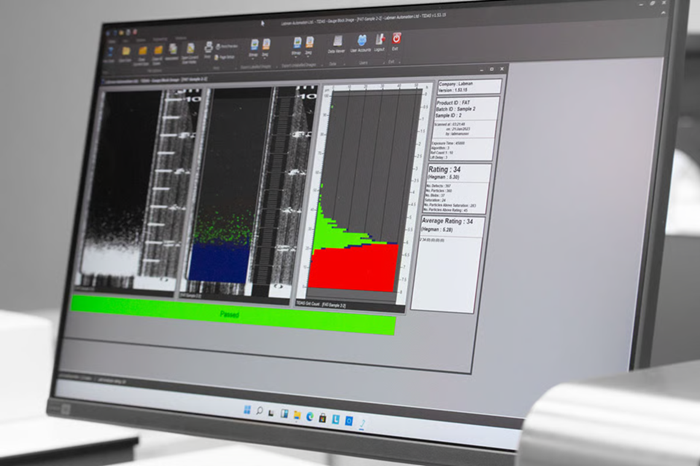

Customized Software: Configure the algorithm to take readings in accordance with the user's standards.

Image Credit: Labman

The software suite provides users with a comprehensive toolkit for customizing operations and analyses. The raw image recorded is shown alongside the digital analysis and micron count. The count determines the exact number of particles per micron slice, resulting in a defined and repeatable rating. Users can use TIDAS to automatically produce a pass or fail against their quality requirements.

The software can be tailored to specific needs, including the ability for users to set ratings and other features. TIDAS works with a variety of gauge sizes to accommodate the current workflow.

Eliminate Human Variance

Image Credit: Labman

Humans excel at many things over robots, but collecting measurements by eye is not one of them. Labman conducted a test to determine the normal discrepancy among users when collecting manual readings from a Hegman gauge. To read about the results of the experiment and the impact this has on production costs, click here.