The BeVision M1 is an automated static image analyzer that provides an accurate analysis of particle shape and size in the range of 0.3-10000 µm. Additionally, the BeVision M1 can play a vital role in the surface cleanliness test.

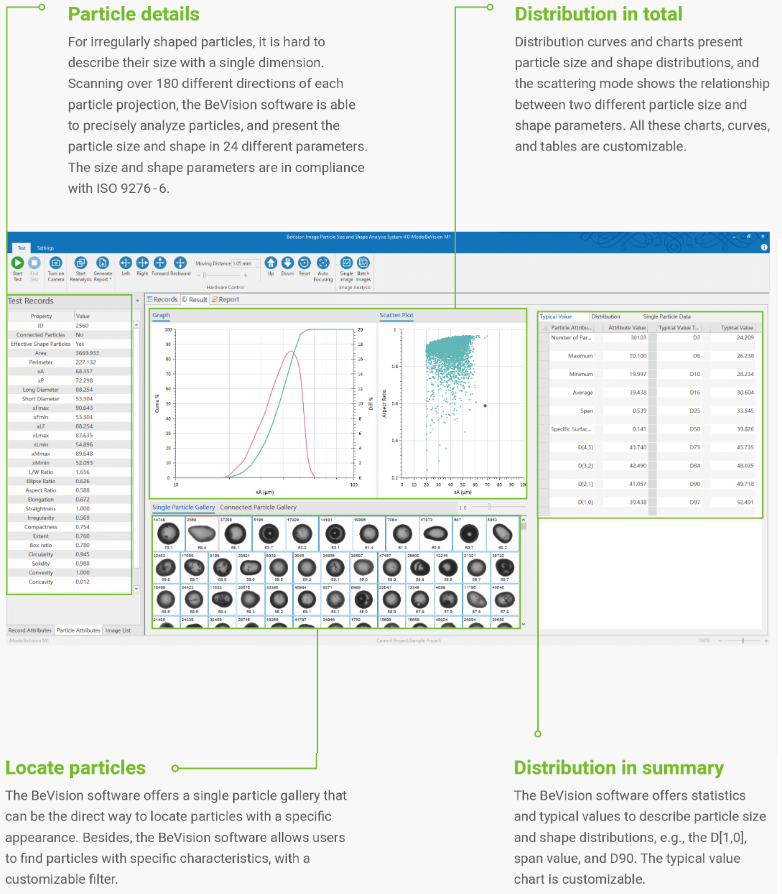

The BeVision M1 can perform analysis more effectively and go beyond the size limit due to the precise auto-moving stage. The BeVision software arranges the data into an all-around validation of particles and assists in evaluating particle size and shape from 34 aspects.

How to Install and Operate BeVision M1

Video credit: Bettersize Instruments

Features and Benefits

- Extremely reproducible measurements

- A high-resolution CMOS camera with 12Mpx

- Results in compliance with ISO 9276-6

- Robust software to make work easier

- Automatic sample stage with high position accuracy

- Measurement range of 0.3 to 10000 µm

- An essential component of surface cleanliness measurements

- 34 distinct variables for particle size and shape

Why Use the Image Analysis Method?

- The image analysis method is easy. Users can capture an image of particles, identify particles, and then measure their size and shape. Each step of image analysis is straightforward and clear.

- Shape analysis can be carried out; it is possible to examine a particle’s shape in addition to its size by looking at it directly.

- The image analysis method identifies the shape and size of every individual particle before adding them up to create a statistic. Details of particle shape or size distribution can be accurately provided.

Why Use the Static Image Analysis Method?

- Clear vision: In static image analyzers, precision microscopes and high-resolution cameras are specifically designed for producing high-quality particle images.

- Undersized particle sensitivity: The static image analysis method is sensitive to undersized particles, and it is even possible to estimate their sizes.

- Small sample volume: The static image analysis method only requires a small number of samples. Only a few micrograms of powder are needed to perform a measurement.

Efficient Scanning Mode and Limit-Breaking Panoramic Mode

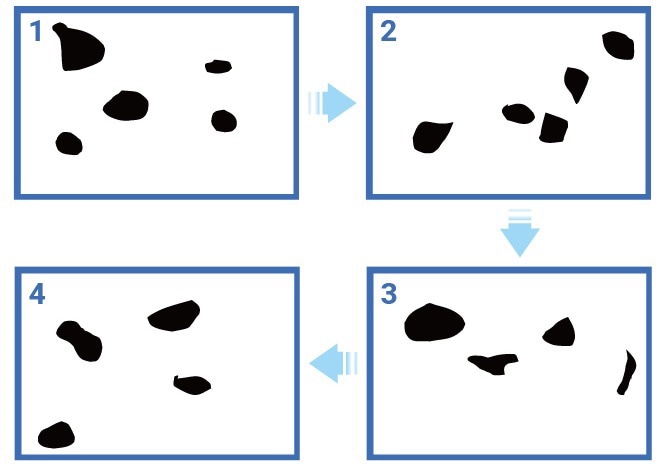

Scanning Mode

The BeVision M1 scanning mode workflow is designed to first capture an image, then analyze the image while moving the stage, then capture the next image once the stage has reached a new position, and then repeat these steps. During the scanning process, the BeVision software will show results in real time. The scanning mode is popular across many industries due to its reliability and efficiency.

Image Credit: Bettersize Instruments Ltd.

Efficient and Reliable Scanning Mode

Compared to the manual test, the automatic scanning process enhances the test efficiency, simultaneously performing image capturing and stage moving pushes the efficiency to the next level.

The effective scanning mode examines several particles in a single test, strengthening the statistical significance of the result.

Both scanning mode and panoramic mode offer reliable statistics. Image Credit: Bettersize Instruments Ltd.

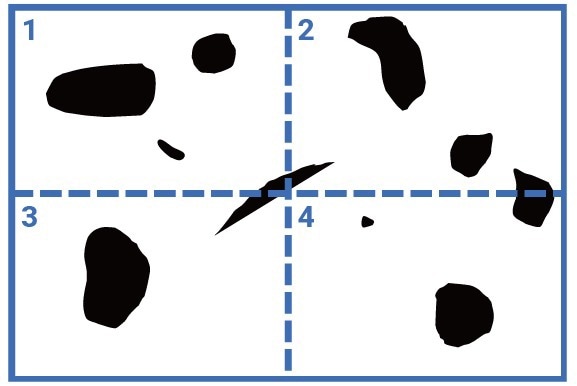

Panoramic Mode

Before analysis, the panoramic mode is used to stitch separate images into a panorama.

A panorama makes it simple to measure the total number of particles in the region and determine their sizes and shapes, even if some are oversized. The accurate particle number is essential to cleanliness inspection.

A Combination of Macro Vision With Micro Details

Panoramas produced by the BeVision M1 can record all the particles dispersed in a millimeter-level region and preserve their shape details. A clear panorama helps to accurately count particles in the macro-region and analyze the shape and size of particles, leaving none out.

Image Credit: Bettersize Instruments Ltd.

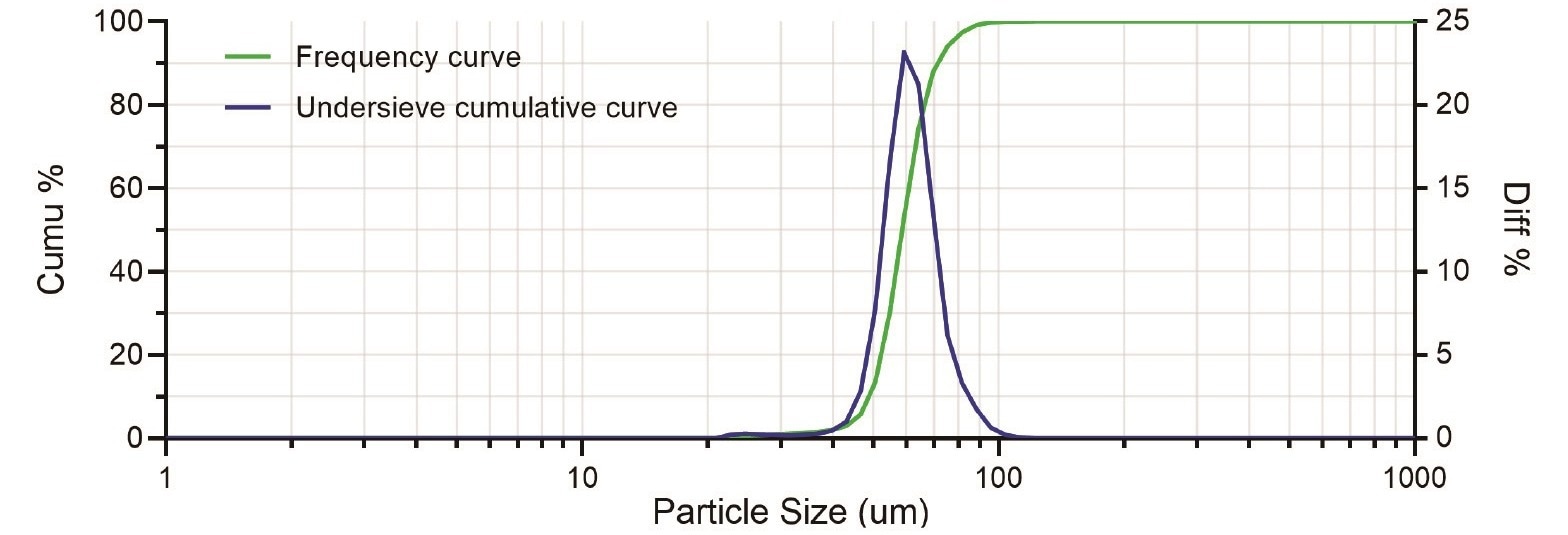

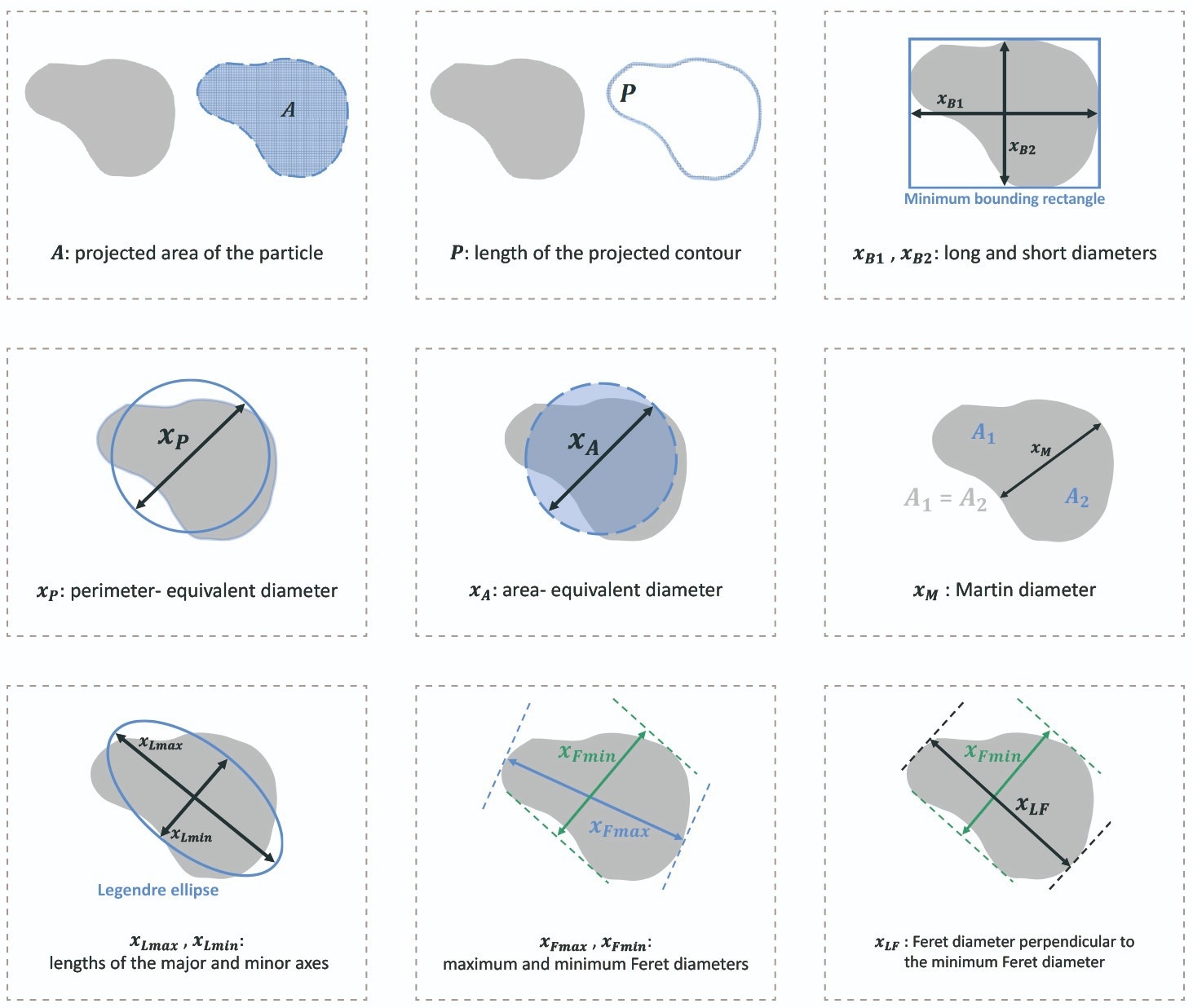

Particle Size Parameters

- Equivalent diameters: Area-equivalent diameter, perimeter-equivalent diameter; Feret diameters: Maximum and minimum Feret diameters, XLF (“length”)

- Martin diameters: Maximum and minimum Martin diameters; Legendre ellipse: Major and minor axes

Image Credit: Bettersize Instruments Ltd.

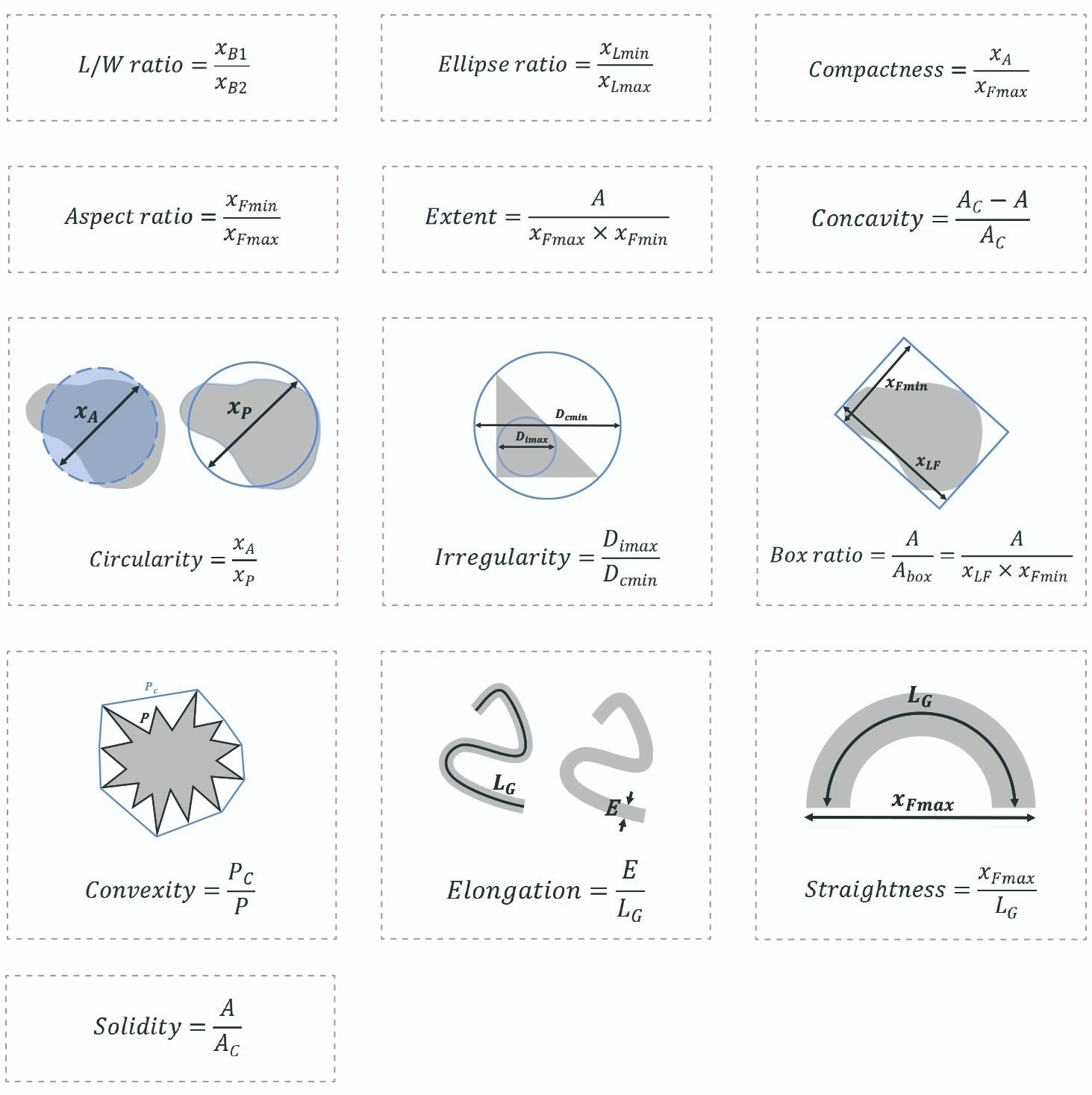

Particle Shape Parameters

- Size difference in two directions: Aspect ratio, L/W ratio, ellipse ratio; Round-likeness and rectangle-likeness: Circularity, irregularity, compactness, extent, box ratio

- Contour concavity: Concavity, convexity, solidity; For elongated particles: Elongation, straightness

Image Credit: Bettersize Instruments Ltd.

BeVision Software: Visualized Insights

Image Credit: Bettersize Instruments Ltd.

Applications

- Abrasives

- Agriculture

- Automotive

- Ceramics

- Metal Powders

- Mining & Materials

- Paints, Inks & Coatings

- Surface Cleanliness

Image Credit: Bettersize Instruments Ltd.

BeVision M1: Image Scanning Particle Size and Shape Analysis