Discover precision gas mixing with the cutting-edge UHP Gas Blender System, designed for a variety of uses in sectors like healthcare, lab research, food packaging, and more. This reliable and adaptable system ensures consistent and controlled gas compositions by enabling precise gas blending to match unique needs.

ASTG-RBS System

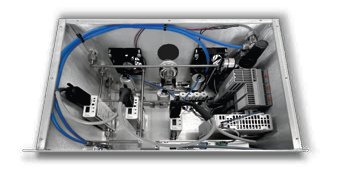

The Remote Blending System combines the ease of use of remote I/O blend modules with the best features of a computer-controlled mass flow blending system. The Control Head and the Dilution I/O® are the two functional components of the system.

Control Head

The Control Head, a 7-inch touch screen-controlled PLC that can also calculate blend ratios, can control up to seven dilution I/O modules. The device features an intuitive HMI interface and fits into a typical 19” rack-mount enclosure.

The device can function in “blend to order” and “single click” modes. When specified, Profinet or Modbus TCP/IP may be used to interface the unit with the customers' PLC networks.

Image Credit: ASTG

Dilution I/O Module

With several decades of gas division, the Dilution I/O® module is a multi-mass Flow Controlled (MFC) remote blend module that efficiently reduces a standard span gas several hundred times while preserving +/- 1% of the initial gas proportions.

This unit is orbitally welded with metal face MFC, diaphragm valves, and VCR glands to ensure purity. Metal diaphragm valves for positive isolation are built into MFC units.

The module features a built-in turbulator loop and back pressure regulator to ensure quick, extremely accurate blending. The module is powered and communicates with the Control Head module and may be installed up to 100 feet (max) from the Control Head.

Image Credit: ASTG

Key Features

- Precision Gas Mixing: Using cutting-edge technology, the Gas Blender System blends gases with unmatched accuracy.

- Wide Application Range: Ideal for a wide range of sectors and uses, such as gas chromatography, medical gas therapy, and pharmaceutical control.

- User-Friendly Interface: Thanks to the user-friendly control panel and digital display, users can easily set and monitor gas mixture parameters. The system's modular architecture provides scalability and flexibility, facilitating easy adaptation to shifting research or production needs. To personalize the system, add different gas cylinders and flow rate options.

- Remote Monitoring: Using optional connectivity features, you can stay in touch and monitor gas blending operations from a distance, improving operational effectiveness.

- Modular Design: The system's modular construction is scalable and flexible, making it simple to adjust to changing research or production demands. To personalize the system, add different gas cylinders and flow rate options.

- Compliance and Certification: The Gas Blender System guarantees that processes fulfill the highest quality and safety standards by adhering to industry standards and regulations.

Image Credit: ASTG