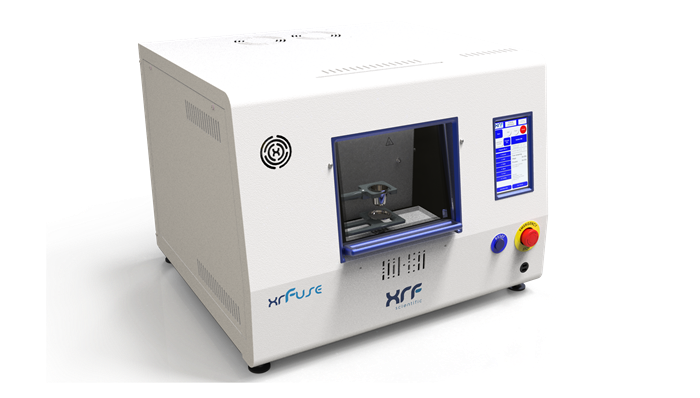

The xrFuse 1 from XRF Scientific is a durable system that enables efficient and seamless preparation of fused glass beads for XRF and ICP analysis.

Image Credit: XRF Scientific

Features

- Upgradable to two positions: Future proof the investment

- Applications: Minerals, materials, and more

- Robust Software: Flexibility for the customized process

- 1300 °C Max Temperature: For challenging applications

Next Generation Fusion Technology xrFuse 1

Image Credit: XRF Scientific

Zero Contamination

The ceramic cradle and holders ensure a contamination-free environment for bead creation.

Reliable and Robust

Designed with very few moving parts, the system provides reliable operation and maximum uptime even in demanding conditions.

Safe Operation

Includes an advanced labware cooling system and all external surfaces remain cool to the touch, ensuring operator safety in a CE-certified design.

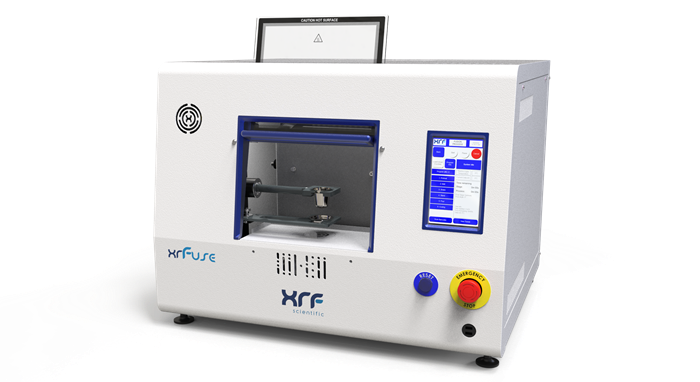

Overview

The next generation of xrFuse fusion technology has arrived, offering absolute process flexibility, higher fusion temperatures, advanced labware cooling, and streamlined maintenance.

The xrFuse 1 is a compact instrument designed for seamless sample preparation of glass beads for XRF and ICP solutions. Ideal for lower-throughput or specialized applications, the unit features a proprietary quick change-out mechanism, allowing users to switch between preparations in a matter of seconds. Its CE-certified cold-to-cold design ensures the system is extremely safe and easy to use.

The entire xrFuse range evolved from robust and reliable technology developed for high-volume, high-uptime applications in Australia's demanding Iron Ore industry. This heritage means every xrFuse is built with durable components and significant lifetimes, ensuring it is truly built to last.

Features

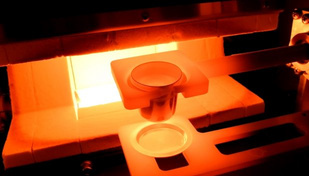

Fast, Precise Heating and Cooling

Image Credit: XRF Scientific

The xrFuse features a highly efficient furnace chamber that quickly reaches the desired fusion temperature. Its system uses separate cooling for crucibles and molds, allowing the user to create the perfect glass bead while also safely cooling crucibles. To ensure sample integrity, the cooling inlets are filtered to prevent external impurities from interfering with the samples. The unit also offers precise temperature control and programmable heating profiles, enabling it to handle the full spectrum of XRF and ICP fusions.

Process Flexibility/ICP

Image Credit: XRF Scientific

Designed for flexible pre-heating and ICP processes, the machine is simple to access, control, and monitor, all at the touch of a button. The user interface is built to provide the consistency required for a production laboratory, while also giving analytical chemists the flexibility to modify parameters as needed.

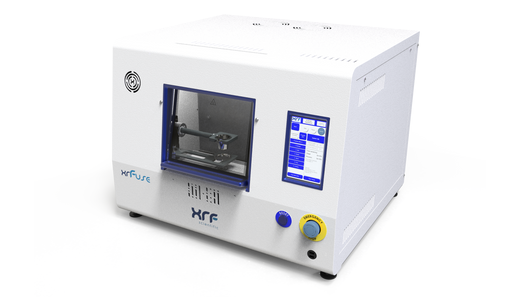

Fully Upgradable

Image Credit: XRF Scientific

Purchase a one-position machine now and upgrade to a two-position system when additional throughput is required. An upgrade kit can be purchased at any time and installed on-site, minimizing downtime and protecting the initial investment.

Streamlined Maintenance and Servicing

Image Credit: XRF Scientific

With a global network of international offices and distributors, XRF Scientific offers simplified maintenance and servicing based on decades of experience supporting fusion instruments worldwide.

Ongoing Support

Image Credit: XRF Scientific

By manufacturing their own fusion machines, flux, and labware, XRF Scientific has gained a unique understanding of lithium borate fusion products and their applications, allowing them to provide comprehensive ongoing support.

- On-site support and preventative maintenance programs

- Guidance on the appropriate selection of flux and standards

- Organization of platinum remake processes

- Technical advice on complex fusion issues

Applications

XRF (Borate Fusions)

Iron ore, nickel, copper, aluminum, rare earths, bauxite, manganese, tantalum, zinc, lead, and uranium, mineral sands, cement, clinker, ferro alloys, ceramics, catalysts, and glass, coal ash, and more.

ICP (Borate and Alkali Fusions)

Refractories, rocks, resistant alloys, chromite, silicates, aluminates, zirconium silicate, aluminosilicates, titanium oxide, barite, dolomite, limestone, lime, and more.

Specifications

Source: XRF Scientific

| . |

. |

| Maximum temperature |

1300 °C |

| Number of sample positions |

1 (upgradable to 2) |

| Throughput |

Up to 4 beads per hour (expandable with upgrade) |

| Programmable recipes |

Up to 100 user-defined recipes with customisable names, plus pre-set programs for common applications. Controlled heating ramp profiles with multiple temperature stages |

| User interface |

Touchscreen control with password-protected access levels |

| Adjustable parameters |

Temperature, step duration, agitation speed and angle, pouring angle, cooling airflow, or magnetic stirring |

| Fusion status display |

Clear indication of total remaining time and individual step progress |

| Crucible cradle / mold holders |

High-purity ceramic |

| Voltage |

2 or 3 Phase 200-220 V or Single Phase 230-240 V in 15 A or 20 A |

| Crucible |

30 g (95 % Pt / 5 % Au or Fusion Alloy), Zirconium or Nickel |

| Molds |

Available in various sizes (95% Pt / 5% Au or Fusion Alloy) |

| Safety |

CE Certified, CSA, ‘Cold to Cold’, CAT 4 rated safety circuit |

| Size and weight |

540 mm (H) x 710 mm (W) x 680 mm (D) - 80 kg |

| Fume extraction |

Integrated extraction system with exhaust adapter |

| Heating elements |

Silicon carbide |

| Connectivity |

USB communication link |