The D-DR 3643 NDT is a large flat panel detector/digital detector array (DDA) suitable for industrial radiography and portability. Ideal for profile images and large objects.

- High-contrast

- Highly sensitive GOS scintillator

- Large format

- 35 × 43 cm active area, ideal for profile images

- Portable and ruggedized

- 6.1 kg / 1 m drop test pass

Important Features

Image Credit: DÜRR NDT GmbH & Co. KG

- 99 μm pixel pitch (5.0 lp/mm)

- Ideal for X-ray and Gamma sources

- Internal shielding allows for operation at 450 kV

- Compact, full-size flat panel detector

- Extremely durable non-glass TFT sensor

- The hot-swap function allows users to change the battery while the device is in operation

- Built-in wireless access point

- Connector for Gigabit Ethernet and power

- Dust-tight and waterproof (IP67)

- 1-meter drop test pass

Technical Data

Source: DÜRR NDT GmbH & Co. KG

| |

D-DR 3643 NDT |

| Active area |

351 mm x 427 mm (13.8" x 16.8") |

Dimensions detector /

incl. housing

(H x W x D) |

384 mm × 460 mm × 15 mm

470 mm x 602 mm x 25 mm |

Weight detector /

incl. housing |

4.1 kg (9 lbs)

6.1 kg (13.4 lbs) |

| Number of pixels |

3548 x 4316 |

| Frame time |

0.5 s to 180 s |

Image transfer time

(wired/wireless) |

3.5 s / 5 s |

| Maximum energy |

450 kV (for long life in typical applications), Isotopes (with typical in-field usage) |

| Pixel pitch |

99 μm |

| Maximum SRb |

100 μm |

| Scintillator |

GOS |

| ADC |

16-bit |

| Interface |

Gigabit Ethernet, WLAN: 2.4 GHz (802.11n) / 5 GHz (802.11ac) |

| Battery |

2 x Lithium-ion (11.55 V, 39.3 Wh) |

| Operating conditions |

20 to 50 °C (-4 to 122 °F), 10 to 90 % humidity |

| Protection level |

IP67 (dust-tight and waterproof) |

| Software |

DÜRR NDT D-Tect X |

| Scope of supply |

Housing, 4 batteries, battery charger, Ethernet adapter cable |

Sample Images

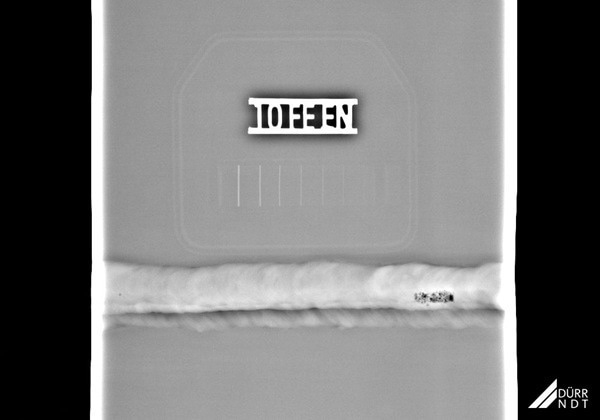

Weld seam, 6 mm steel plate, X-ray (ISO 17636-2 Class B compliant). Image Credit: DÜRR NDT GmbH & Co. KG

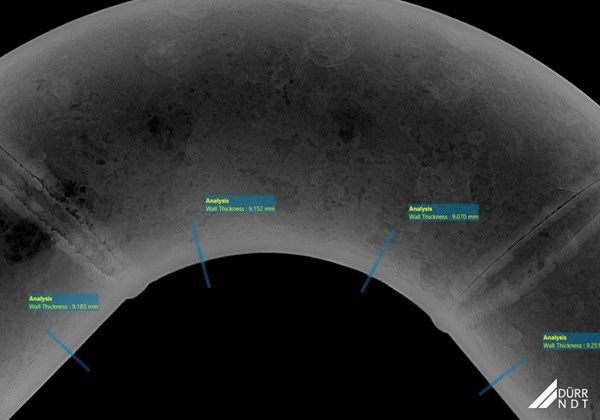

With the Advanced Wall Thickness Tool of D-Tect X, you can easily analyze the wall thickness of a pipe. Image Credit: DÜRR NDT GmbH & Co. KG

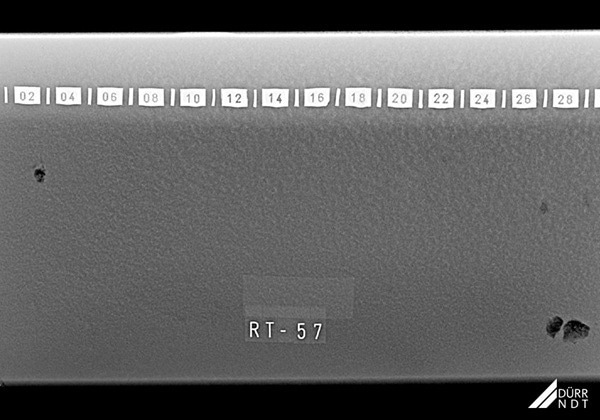

Aluminium casting, t = 10 mm, shrinkage cavity. Image Credit: DÜRR NDT GmbH & Co. KG

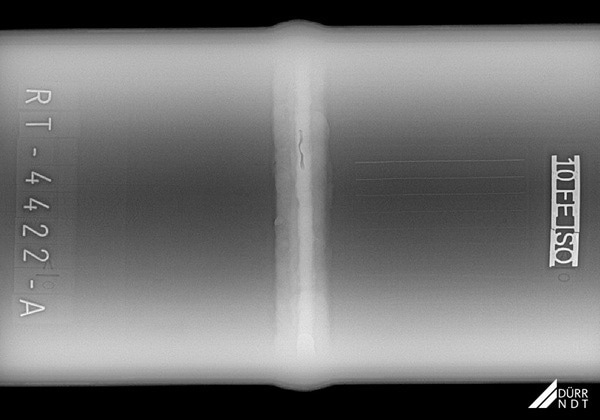

Stainless steel, perpendicular technique, slag inclusion. Image Credit: DÜRR NDT GmbH & Co. KG

Accessories

System Control Unit (SCU) Mini

Image Credit: DÜRR NDT GmbH & Co. KG

Image Credit: DÜRR NDT GmbH & Co. KG

An optional access point is provided for wired power supply to detectors and exposure signal transfer (if the X-ray generator supports it).

CCP120B/CP160B X-Ray Generator

Image Credit: DÜRR NDT GmbH & Co. KG

Image Credit: DÜRR NDT GmbH & Co. KG

Portable X-ray generators with constant potential outputs of 120 kV/160 kV. Only available in a bundle with an X-ray imaging device and software.