Atomfab from Oxford Instruments offers quick, low damage, low CoO production plasma ALD processing for GaN power and RF devices.

ATOMFAB ALD System - Oxford Instruments Plasma Technology

Video Credit: Oxford Instruments Plasma Technology

PACE

Atomfab is known to be the quickest remote plasma production ALD system that is commercially available.

Solutions for Production Needs

- Competitive CoO

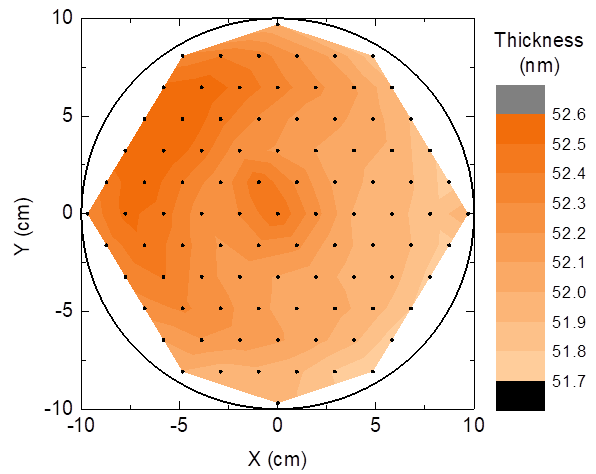

- Outstanding film uniformity

- High material quality

- Fast, easy maintenance

- Quicker cycles times, high throughput

- Clusterable and automated wafer handling

- Low substrate damage

Image Credit: Oxford Instruments Plasma Technology

Performance

Atomfab's ALD technology provides accurately controlled ultra‑thin films for sophisticated applications on the nanometer scale, with a conformal coating of sensitive substrate structures.

Process Benefits for Passivation of Power and Rf Devices

- Plasma surface pre-treatments

- High quality deposition with low film contamination

- Low particle levels

- Guaranteed processes setup by our engineers

- Lifetime process support for additional/new processes

- Low-damage plasma processing

- Short plasma exposure times that allow for high throughput

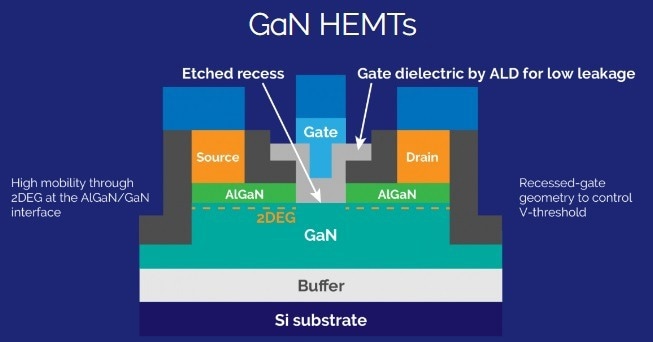

Advantages of Plasma ALD for GaN, Power, and RF Devices

- Remote plasma ALD with controlled ion energy from near zero to 30 eV

- With plasma pre-treatment prior to deposition to enhance interface quality

- Low damage, uniform deposition

- ALD passivation, gate dielectric by Al2O3 films

Increased throughput and improved uniformity to bring remote plasma ALD to production. Image Credit: Oxford Instruments Plasma Technology

Plasma

Revolutionary plasma source: Atomfab makes use of a patent-pending remote source that has been specifically developed for atomic-scale processing.

- Low damage for sensitive substrates for utmost device performance

- Short plasma times (250 milliseconds) enabled by patent-pending AMU

- Low reflected power and reproducible strike time for high yield

- Short strike time (80 milliseconds) for high throughput

- Quick cycle times and reliability with even film deposition and plasma exposure

| Plasma ALD Al2O3 at 300 °C |

Specification |

| Within wafer thickness uniformity |

<± 1.0% |

| Wafer-to-wafer thickness repeatability |

<± 1.0% |

| Breakdown voltage |

≥ 7.0 MV/cm |

Image Credit: Oxford Instruments Plasma Technology