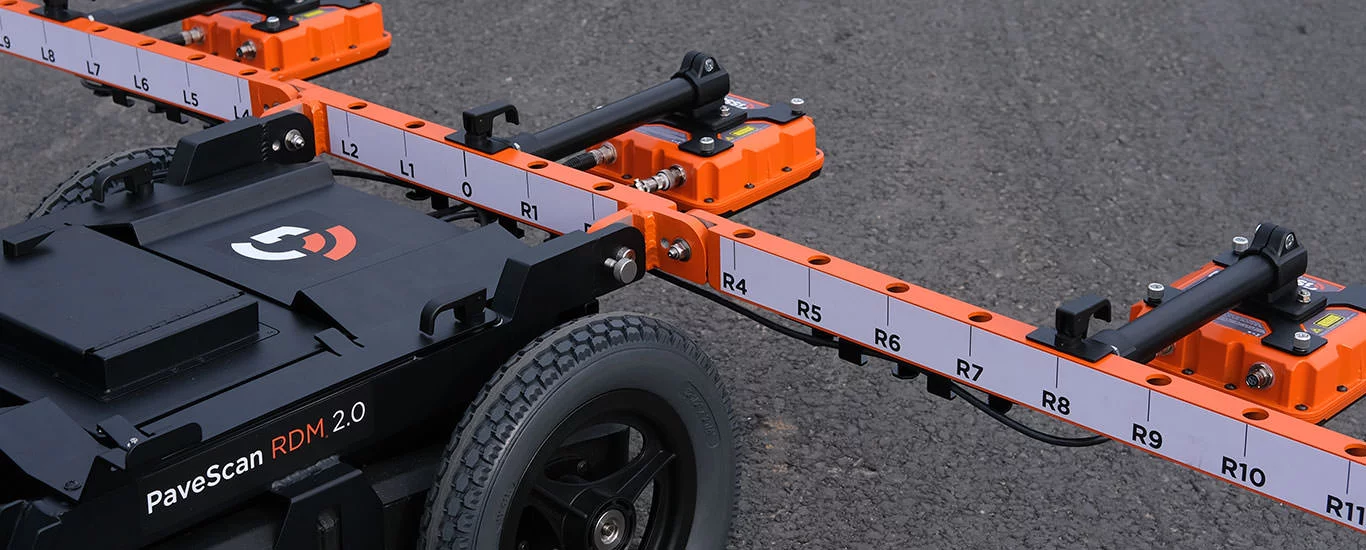

PaveScan RDM 2.0 from Geophysical Survey Systems Inc. (GSSI) is the second-generation asphalt density assessment tool that is perfect for unveiling inconsistencies that take place at the time of the paving process, such as poor uniformity and considerable variations in density. By detecting these issues, PaveScan RDM 2.0 aids to avoid premature failures like road raveling, cracking and deterioration along joints.

As of April 2019, this pavement density measurement technology is an accepted American Association of State and Highway Transportation Officials (AASHTO) specification, PP 98-19.

Image Credit: Geophysical Survey Systems

Image Credit: Geophysical Survey Systems

Applications

- Determining pavement non-conformity

- Non-destructive testing of asphalt compaction

- Quality assurance/quality control of new pavements

Features

- User manual

- 2 GHz sensor (1 or 3)

- Concentrator box

- Panasonic Toughpad G1

- Lithium-ion battery (2)

- 4-wheel cart

- Dual-bay battery charger

- 2.1-m digital control cable(s)

- Two-year warranty

Modern Technology to Determine New Pavement Quality

The PaveScan RDM 2.0 makes use of the dielectric measurements of new pavement to identify pavement quality and uniformity. This is known to be the world’s first.

Image Credit: Geophysical Survey Systems

Innovative Technology

The PaveScan RDM 2.0 provides a simple and inexpensive assessment tool to non-destructively identify asphalt dielectric at the time of application. This system is perfect for unveiling inconsistencies that take place during the paving process, such as poor uniformity and considerable variations in density.

Image Credit: Geophysical Survey Systems

Groundbreaking Solutions

The PaveScan RDM 2.0 is the premier asphalt test method to determine areas of non-conformity in new pavement. It could be deployed with two distinct survey techniques: using the percent voids or dielectric values. There are no site hazards or need to close off work areas as is the case with nuclear gauges or radioactive alternatives.

Image Credit: Geophysical Survey Systems

Data Visualization

From technician to engineer, the PaveScan RDM 2.0 is simple to use. Thanks to persistent real-time onscreen data output, GPS integration and export options, this system is perfect for government transportation agencies and paving contractors in a similar way.

Image Credit: Geophysical Survey Systems

Data Examples

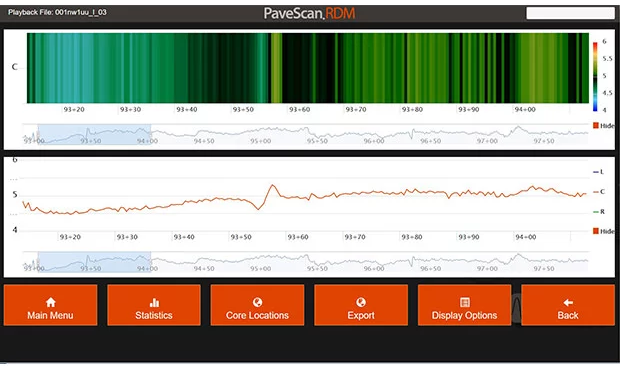

Single Sensor

The color map indicates anomalies in the direct measurement, thus allowing technicians to clearly identify areas of interest.

Image Credit: Geophysical Survey Systems

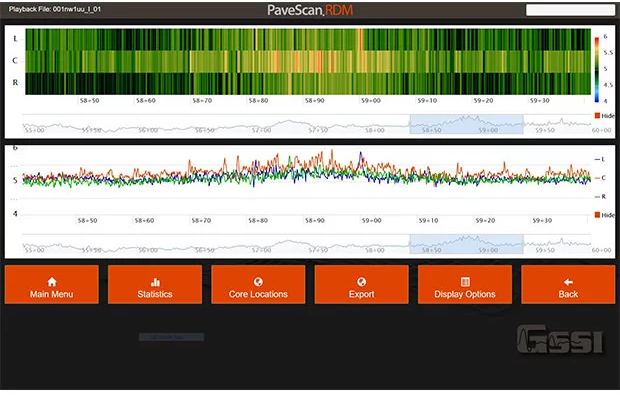

Three sensors

The line chart illustrates a three-sensor system, where each line adds up to the dielectric output of the sensor.

Image Credit: Geophysical Survey Systems

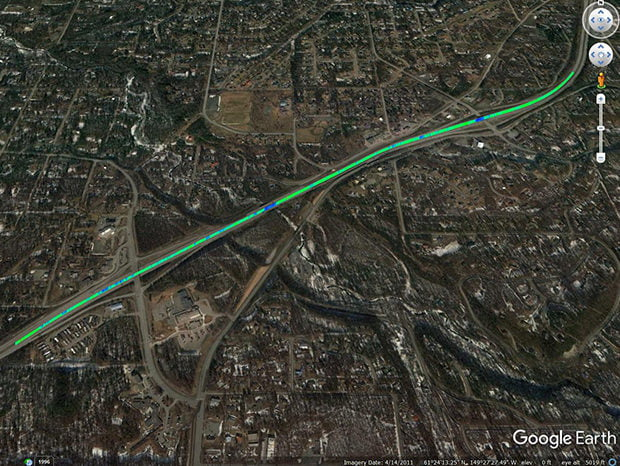

Google Earth Image

This data illustrates a Google Earth image that has been exported as a .kml file instantly from PaveScan RDM. This image exhibits the density levels of newly laid compacted pavement. The blue areas are low density and the middle blue areas are bridges.

Image Credit: Geophysical Survey Systems

Specifications

Source: Geophysical Survey Systems

| Tablet computer |

| Display |

10.1" WUXGA 1920 x 1200 with LED backlighting |

| Processor |

Intel® i5-7300U |

| Available ports |

Ethernet, USB, HDMI |

| Battery |

Li-Ion Battery Pack (10.8 V), 4 hours |

| Operating temperature |

-28 °C to 60 °C (-18 °F to 140 °F) |

| Environmental rating |

IP65 |

| Drop spec |

MIL-STD-810G |

| System specifications |

| Data format |

.csv |

| Maximum output resolution |

.4 inch (1 cm) |

| Operating mode |

Survey wheel distance-based data collection |

| Power source |

2 x 10.8 V 8.2 AH batteries |

| Diagnostic |

Battery indicator status, hard disk capacity |

| Measurement specification |

| Repeatability (Dielectric) |

+/- 0.08 (value obtained from HDPE validation blocks) |

| Accuracy (Dielectric) |

+/- 0.08 (value obtained from HDPE validation blocks) |

| Minimum/Maximum dielectric |

2 to 16 |

| Mechanical |

| Dimensions |

One sensor cart system – 36.9 kg (81.4 lbs), Three sensor cart system – 42.9 kg (94.6 lbs) |

| Environmental rating |

IP65 |

| Operating temperature |

-28 °C to 60 °C (-18 °F to 140 °F) |

| Storage temperature |

-55 °C to 85 °C (-67 °F to 185 °F) |

Accessories

The upgrade kit for the PaveScan enables single sensor users to upgrade their systems to three sensors for better pavement coverage. This accessory consists of two cables, two sensors and arm extensions.

Image Credit: Geophysical Survey Systems