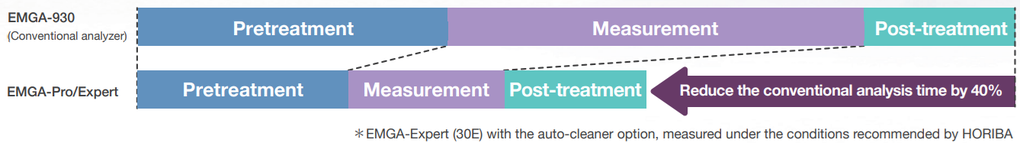

The EMGA-Expert Oxygen/Nitrogen/Hydrogen Analyzer dramatically cuts down analysis time and expenses while boosting accuracy and capabilities. As a top-selling model for over four decades since its 1980 launch, the EMGA series has consistently delivered industry-leading analysis accuracy, providing strong support for materials research, development, and quality assurance.

Through extensive efficiency enhancements, the company has achieved an approximate 40% reduction in analysis time and operational costs compared to the earlier model. It features an automated system to enhance operator safety and decrease operators' time working.

Typical Applications:

- Ceramics

- Energy: Materials for lithium-ion battery, fuel cell, electrolyzer

- Electric parts

- Steel and non-ferrous alloy (metallurgy): Iron, copper, nickel, aluminum, zinc, tungsten carbide

- Mineral: Cokes, lime stone, coal, silicone, rare-metal

- Others: Catalyst, rubber, carbon black, silica, cement

- Semiconductor: Silicon, poly-silicon, GaN

Features:

Overwhelming Speed - Achieved a 40% Reduction in Typical Analysis Time

Image Credit: HORIBA

HORIBA's unique sequence algorithm optimizes gas flow, resulting in a shorter analysis cycle time compared to the previous models.

Highly Accurate Analyses from ppm to % across a Wide Range of Measurements

“I require my samples to be analyzed with precision, consistency, and reliability.”

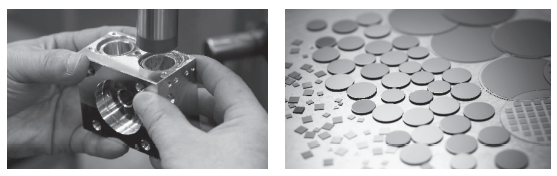

Proven NDIR Gas Detection Technology

Image Credit: HORIBA

The EMGA Series incorporates Non-Dispersive Infrared (NDIR) gas detectors that are entirely developed, designed, and manufactured by HORIBA. Utilizing meticulous design and advanced production techniques, these detectors undergo stringent quality control throughout every stage, from the precise polishing and assembly of components to the careful adjustment and verification of stable operation.

This rigorous quality assurance ensures that the EMGA Series delivers stable and highly reliable measurements over an extended lifespan. Furthermore, HORIBA has internally developed the Thermal Conductivity Detector (TCD) to ensure that these analyzers achieve optimal performance.

Significantly Reduced Both Labor and Consumable Costs

“Less downtime, less running cost!”

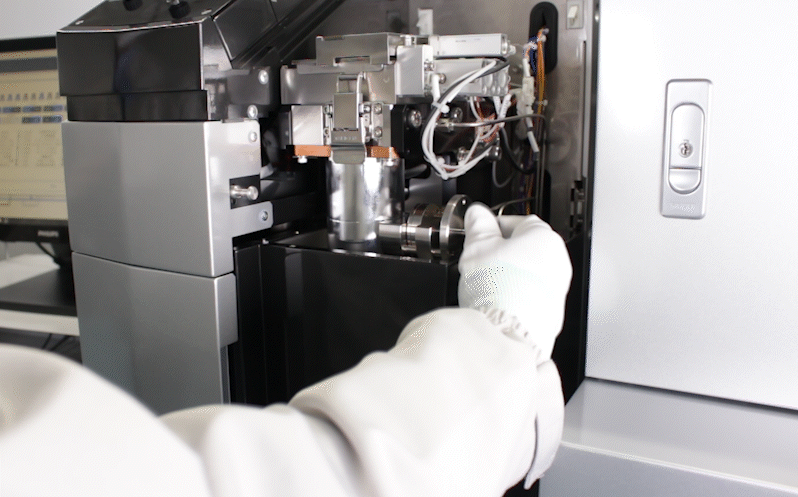

Easy Replacement of Lower Electrodes

Image Credit: HORIBA

The redesigned chip replacement process is now significantly easier: removing the lower electrode cap to exchange the chip requires no specialized tools. This streamlined mechanism reduces the replacement time to approximately one-tenth of the previous duration.

New Dust Filter

The updated dust filter replacement mechanism only requires exchanging the thin filter within the holder. This improvement has also significantly decreased the filter replacement frequency to one-tenth of what was previously needed, meaning replacement is only necessary after approximately 500 measurement cycles.

Image Credit: HORIBA

Significantly Reduced the Carrier Gas Consumption

Using a 47-liter gas cylinder now allows for a significantly higher number of measurements, increasing from approximately 1,400 to 2,300.

Automation Options

To further optimize the workflow with the EMGA Series, HORIBA offers three optional automation units:

Crucible Loader: Employs a rotary mechanism for the accurate picking and placement of crucibles. It can hold a maximum of 100 crucibles.

Auto Sampler: Enables the automated loading of samples and fluxes, with a capacity of up to 22 items.

Auto Cleaner: This device features two rotating brushes that automatically clean the upper and lower electrodes after each measurement cycle.

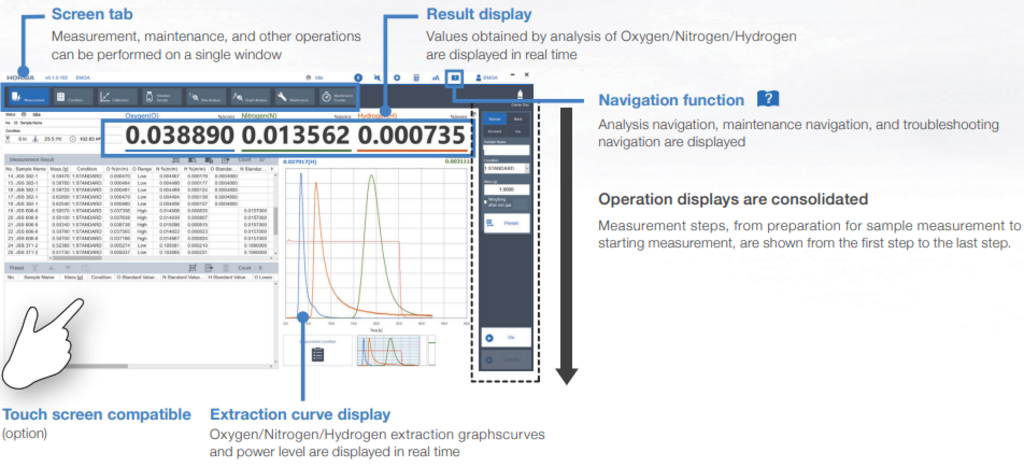

More Intuitive Software for Easy Operation

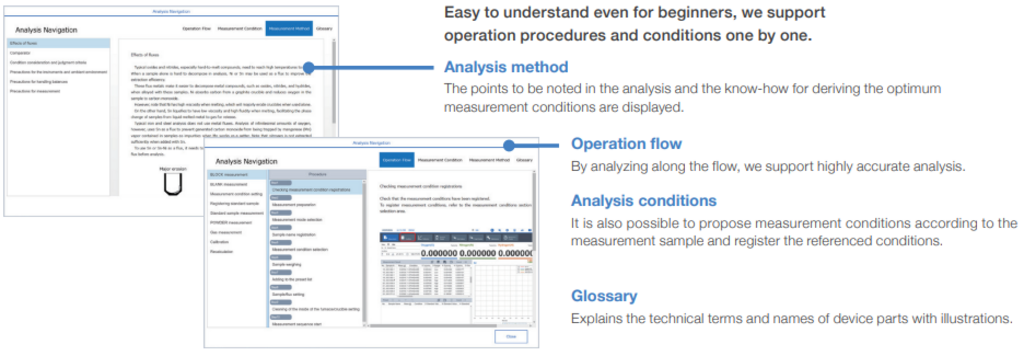

Advanced Operation Software

The EMGA Series features its own intuitive operating software, designed with a focus on user-friendliness through optimized layout, operating menus, and functions. Furthermore, it incorporates self-diagnostic monitoring to assess the status of connected devices, an integrated alarm system, and enhanced navigators to streamline daily operations.

Image Credit: HORIBA

Enhanced Operator Assistance

Moreover, the software is equipped with self-diagnostic monitoring that checks the status of connected instruments, an alarm system, and three helpful navigators. These navigators provide recommendations for optimal sample conditions, assist in troubleshooting errors, and remind users when maintenance is needed. These integrated features enhance daily operations and contribute to efficient analysis.

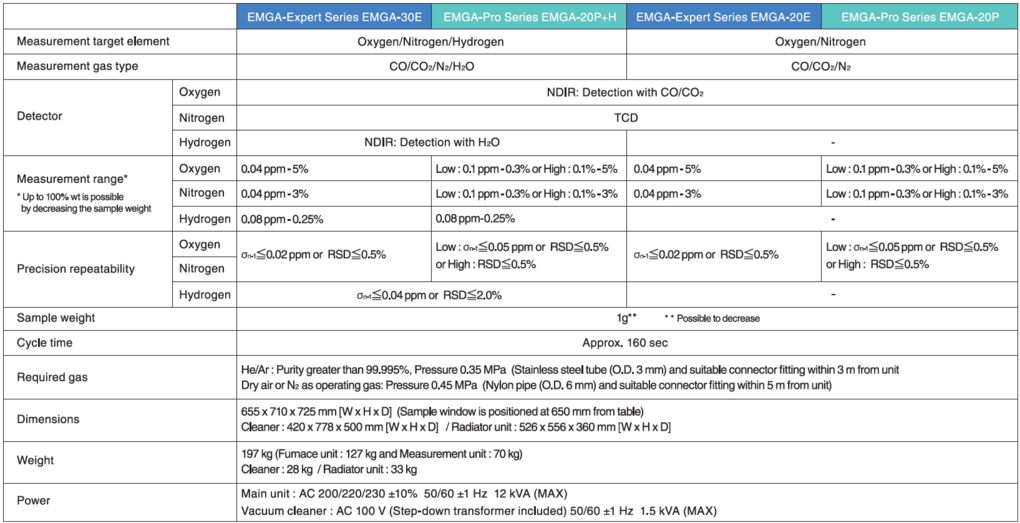

Specifications

Selectable option

Source: HORIBA

| Model |

Auto Cleaner |

Crucible Loader |

Auto Sampler |

C-50 (Gas conversion) |

ONH 3components |

Customization / Special Acceptance |

| EMGA-Pro |

✔ |

✔ |

✔ |

|

|

|

| EMGA-Expert |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

Specifications

Source: HORIBA

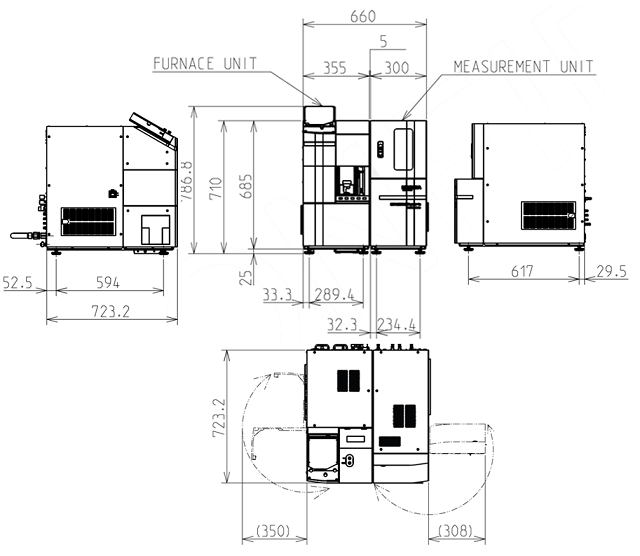

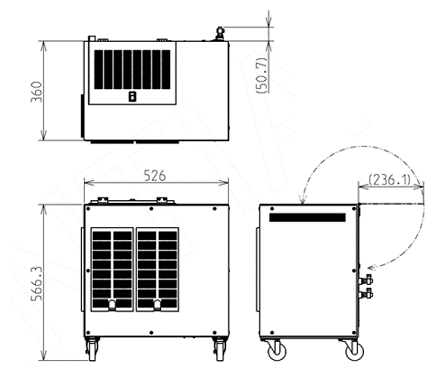

Dimensions

Image Credit: HORIBA

Applications

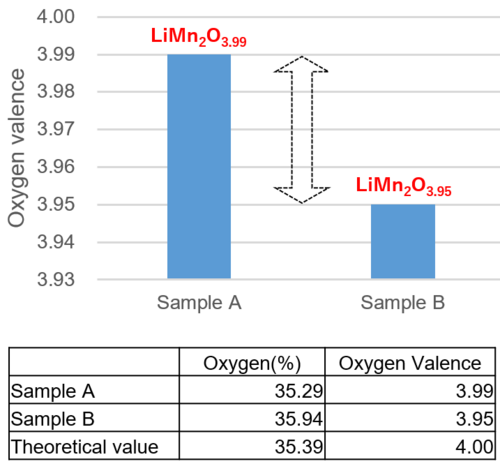

Measurement of Oxygen Deficiency in Lithium Manganate

Image Credit: HORIBA

Spinel-type lithium manganate (LiMn2O4-σ) exhibits variations in discharge behavior due to minor compositional changes resulting from oxygen deficiency. While particle size and crystal structure differences also influence the discharge characteristics of lithium manganate batteries, the oxygen bonding ratio is also a significant factor. Notably, samples with fewer oxygen bonds tend to display inferior discharge performance.

Oxygen, Nitrogen, and Carbon Analysis in Nuclear Fuels

Image Credit: HORIBA

Nuclear energy is gaining significant global interest to enhance energy security and decrease CO2 emissions. Twenty-five nations have jointly declared a cooperative strategy aiming for the ambitious target of tripling global nuclear power generation capacity by 2050 compared to 2020 levels. Ensuring the safety of nuclear fuel and enhancing its performance is paramount, necessitating strict control over the oxygen, nitrogen, and carbon content within nuclear materials.

Purity Analysis in Precious Metal Recycling

Image Credit: HORIBA

Although precious metals like gold (Au), silver (Ag), platinum (Pt), and palladium (Pd) are finite resources, they are crucial for electronic components and functional materials. Consequently, to ensure resource availability and reduce costs, separating and extracting these necessary precious metals from end-of-life products and recycling them into high-purity forms is vital. Contaminants such as light elements like carbon, sulfur, oxygen, and nitrogen must be carefully controlled. For instance, gold used in electronic devices must have a minimum purity of 99.999%.

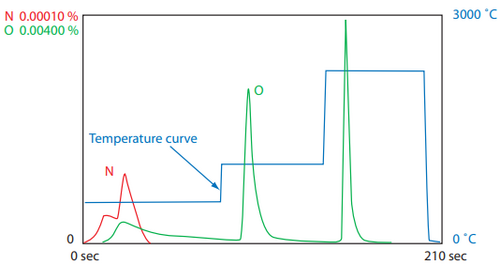

Analysis of Oxygen (O) and Nitrogen (N) in Metal 3D Printer Materials

Table 1. Analysis results for oxygen (O) and nitrogen (N) in Ti material. Source: HORIBA

| Sample weight [g] |

Oxygen [mass %] |

Nitrogen [mass %] |

| 0.0504 |

0.0739 |

0.0114 |

| 0.0503 |

0.0718 |

0.0153 |

| 0.0506 |

0.0725 |

0.0171 |

| Average |

0.0727 |

0.0146 |

Stainless steel, titanium (Ti), aluminum (Al), and copper (Cu) are frequently used metals in 3D printing, and customers have indicated a need for rapid quantification of oxygen (O) and nitrogen (N) content in these materials. For instance, a high oxygen (O) concentration in titanium can form oxides, potentially causing flaws in the final 3D-printed component.

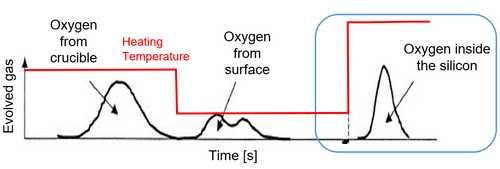

Quantitative Analysis of Oxygen in Silicon Wafers

Image Credit: HORIBA

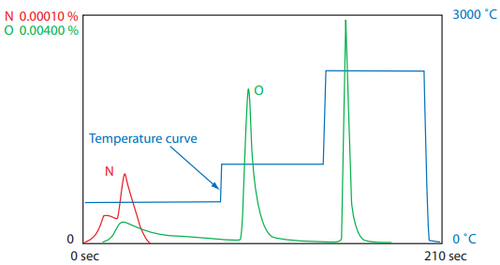

The electrical resistance of silicon wafers is highly sensitive to the oxygen concentration. Consequently, even trace amounts of oxygen must be carefully controlled during silicon wafer production. However, analyzing oxygen levels in heavily doped single crystals presents a specific challenge. The distinct characteristics and high doping concentrations of these materials complicate oxygen analysis. Impurities and dopants present in these crystals can interfere with accurately measuring oxygen concentration using Fourier Transform Infrared (FT-IR) spectroscopy.

Oxygen and Nitrogen Determination in Boron Nitride

Image Credit: HORIBA

EMGA-920 can accurately measure both high concentrations of nitrogen and low concentrations of oxygen simultaneously and precisely.

Oxygen and Nitrogen Determination in Aluminum Nitride

Image Credit: HORIBA

EMGA-920 accurately measures high Nitrogen levels while preserving the necessary precision for determining Oxygen content in Aluminum Nitride (AIN).

The Hydrogen Analysis of Solid Samples

I

Image Credit: HORIBA

The demand for analyzing hydrogen content in diverse sample materials is steadily growing in the marketplace each year.

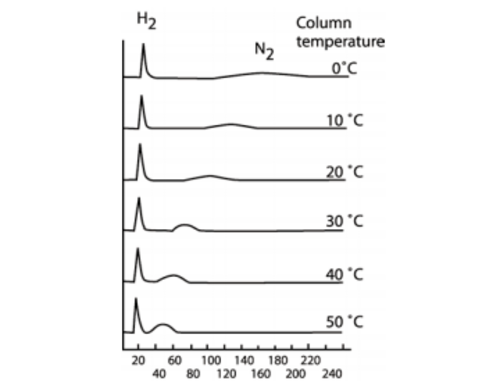

Hydrogen Analysis in Steel and Metals: Solid Extraction or Fusion

The EMGA series is engineered for precise determination of hydrogen content in a variety of materials, including ferrous and non-ferrous metals, semiconductors, and electronic components. Hydrogen is released from the sample by melting it in an inert gas atmosphere and then quantified using a highly sensitive thermal conductivity detector.

Alternatively, hydrogen can be extracted without melting the sample by heating it below its melting point.