The newest iteration of the LA series propels scientific discovery for the future through its user-friendly software, specialized accessories, and exceptional performance. The LA-960V2 proudly upholds HORIBA's long-standing reputation for pioneering design within the industry.

Image Credit: HORIBA

Image Credit: HORIBA

Features

HORIBA’s Groundbreaking Optical Design Perfects the Static Light Scattering Particle Sizing Technique

Advanced Detector Design

The system's overall performance is influenced by the number of detectors, the range of angles they can measure, and how they are arranged.

Superior Instrument-to-Instrument Precision

The LA-960V2 is engineered to deliver consistent results irrespective of when it was made, the operator's expertise, or where it is used. Experience unparalleled agreement between instruments without the need for complex correlation procedures.

Automatic Laser Alignment in Seconds

Thanks to computer-controlled laser alignment, you can achieve consistently perfect measurements. HORIBA's innovative method completes the alignment process in mere seconds.

Guaranteed Accuracy and Precision

The LA-960V2 is a sophisticated particle size analyzer that can precisely measure NIST-traceable size standards with an accuracy of ±0.6% of their specified value. It also fully adheres to ISO 13320 guidelines for measuring material sizes at the D10, D50, and D90 percentiles.

State of the Art Sampling Systems

Wet Measurement

Sample-to-Sample Analysis in Less Than 60 Seconds

The wet circulation system for the HORIBA LA-960V2 offers a user-friendly, rapid, and highly effective way to disperse samples. This standard wet unit has a software-controlled dispersant fill pump, liquid level sensor, circulation pump, a robust 30 W in-line ultrasonic probe, and a drain valve, enabling true one-touch operation. This sophisticated design ensures highly consistent and reproducible particle size measurements.

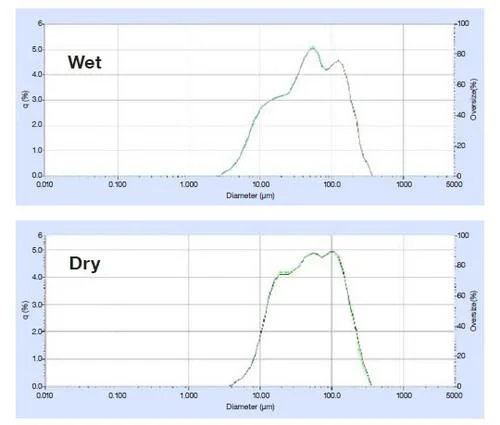

Dry Measurement

Automated, Powerful Dry-Powder Dispersion

The LA-960V2 PowderJet incorporates several exclusive and patented technologies to deliver the most consistent and repeatable dry particle size measurements. Its Auto Measurement feature allows for automated control of vacuum levels, air pressure, powder flow rates, start/stop parameters, measurement duration, and data analysis. This versatile design can handle many applications, including analyses of small sample quantities, easily fragmented powders, and highly clumped materials.

Smart Scans – Trigger Function

This feature is especially beneficial for accurately measuring very valuable materials. When the available sample is limited or the powder does not flow easily, the Trigger function provides precise control over starting and stopping the measurement process.

Self-Adjusting Powder Flow

Historically, maintaining a consistent powder flow has been the primary obstacle in dry powder analysis. The LA-960V2 PowderJet overcomes this challenge with an intelligent feedback system that automatically adjusts to maintain a constant level of laser light passing through the sample. This consistent transmittance is a critical element in achieving reliable and reproducible dry powder size measurements.

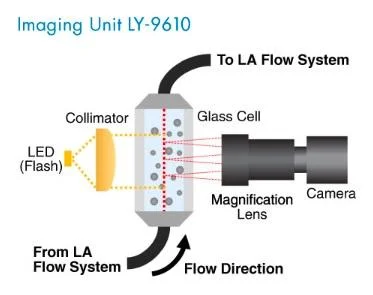

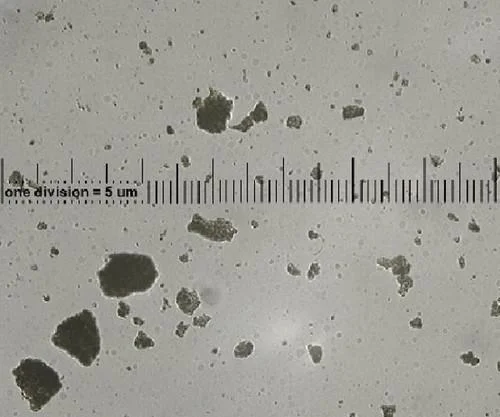

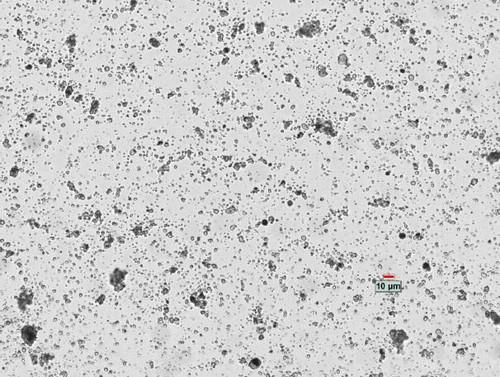

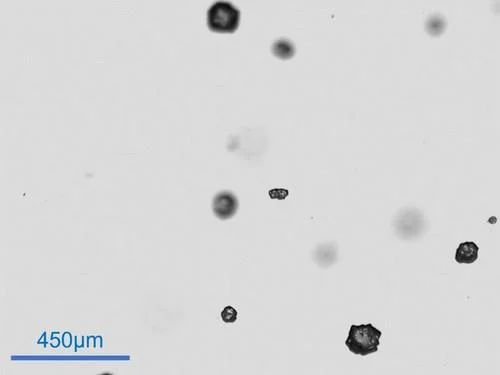

LY-9610 Imaging Unit

The integrated imaging unit provides live observation, captures particle images, and enables assessment of particles within the wet circulation system, all without increasing the instrument's size!

Image Credit: HORIBA

Features

- Detect and quantify even minute amounts of atypical particles (such as contaminants, large particles, and agglomerates)

- Identify bubbles within the wet circulation system

- Gain deeper insight into sample dispersion (observing the impact of stirring, sonication, and the addition of surfactants or stabilizers)

- Perform particle shape analysis (requires optional Advanced Software)

Functions

- Image capture and particle detection

- Automated detection of large particles

- Automated detection of bubbles

- Real-time trend graph and histogram displaying the equivalent circular diameter

- Histogram illustrating shape distribution (aspect ratio, roundness, length, width) when used with the optional advanced software.

Specifications

Laser Scattering Particle Size Distribution Analyzer Model: LA-960V2

Source: HORIBA

| . |

. |

| Measurement Principle |

Mie scattering and Fraunhofer diffraction |

| Measurement Range |

10 nm - 5000 μm (Option dependent) |

| Measurement Time |

Typical measurement takes 60 seconds from liquid filling, sampling, and measurement to rinsing. |

| Measurement Method |

Circulation measurement or fraction cell measurement (Fraction cell is optional) |

| Sample Quantity |

Approximately 10 mg - 5 g (Depending on the particle size, distribution and density) |

| Dispersing Volume |

Approximately 180 mL for standard pumping system, 5/10/15 mL for Fraction Cell accessory, Manual filling: 35 mL, Automatic filling: 40 mL for MiniFlow accessory. Approximately 1 L of LiterFlow option. |

| Compatible Liquids |

A type: Water*, S type: Common organic solvents (*also, mixtures with small volumes of ethanol) |

| Communication |

USB 2.0 (USB 3.0 required for some options) |

| Light Sources |

Red solid state 5 mW laser diode (650 nm), Blue solid state 3 mW LED (405 nm) |

| Dispersion System |

In-line ultrasonic probe: 30 W, 20 kHz, adjustable levels

Circulation pump: Fully automated fill and circulation pumps, 15 adjustable speeds, 4 selectable fill levels, 15 selectable circulation speeds (max: 10 L/min) |

| Operating Conditions |

15〜35 °C (59 to 95 °F), relative humidity 85% or less (no condensation) |

| Power |

AC 100-240 V 50/60 Hz, 300 VA |

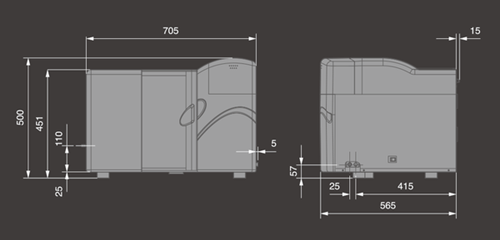

| Dimensions |

705 (W) × 565 (D) × 500 (H) mm |

| Mass |

54 kg |

| Computer Requirements |

Windows PC with available USB ports, Windows 10 64-bit or Windows 11 64-bit. Contact for additional details. |

※Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

PowderJet Dry Feeder Accessory

Source: HORIBA

| . |

. |

| Dispersion Method |

Compressed air dispersion using Venturi nozzle |

| Sample Delivery |

Vibrating feeder |

| Sample Disposal |

Vacuum-driven evacuation |

| Measurement range |

100 nm - 5000 μm |

| Controls |

Communication: Serial cable to LA-960V2 main unit

Measurement: Vibrating feeder controlled automatically via feedback or manually by user, Vacuum AUTO/OFF, Compressed Air AUTO/OFF, Air pressure adjustable from 0 - 0.4 MPa in 40 steps |

| Measurement Time |

Typical measurement takes 2 seconds or longer. |

| Operating Conditions for PowderJet |

15〜35 °C (59 to 95 °F), relative humidity 85% or less (no condensation) |

| Dimensions |

332 (W) × 321 (D) × 244 (H) mm (not including dimensions of projections and LA-960V2 measurement unit) |

| Power for PowderJet Operation |

AC 100 V, 120 V, 230 V, 50 or 60 Hz, 1500 VA (Including vacuum but LA-960V2 measurement unit) |

| Compressed Air Supply Pressure |

Compressed air supply origin pressure: 0.4 - 0.8 MPa

Compressed air controlling range: 0.01 - 0.4 MPa |

| Compressed Air Connection |

Quick connector for resin tube with 6 mm outer diameter

(Compressed air supply equipment must be provided separately) |

| Remarks |

Vacuum is equipped as standard |

※When ordering the PowderJet, please specify the power requirements for the final destination.

※Above specifications and functionality are valid only when PowderJet is installed on the LA-960V2 main unit and controlled using the LA-960V2 software.

※Manufacturers and models indicated for vacuum, air compressor, computer, monitor, and/or printer are subject to change.

◎Air Compressor

Inlet pressure within 0.5 - 038 MPa, Tank capacity 26 L or larger, Flow rate 45 L/min or faster

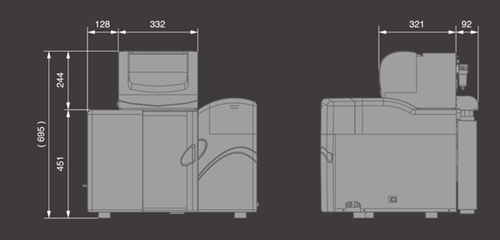

LY-9610 Imaging Unit

Source: HORIBA

| . |

. |

Observed Measurable Range

for image analysis |

5 μm - 1000 μm*

*5 μm for size and 9 μm for shape as per ISO 13322-2. |

| Pixel Size |

0.8 μm |

| Speed |

≧ 4 fps |

| Functions |

Histogram of equivalent circle diameter.

Shape Parameters: Aspect ratio*, Circularity*, Length*, Width*

Trend graph of equivalent circle diameter.

Post Analysis of captured image (zoom-in/out, measuring size). |

| Communication |

USB 3.0 |

*Optional Advanced software

Accessories

Source: HORIBA

| Components |

LA-960N2 |

LA-960A2 |

LA-960S2 |

LA-960W2 |

LA-960L2 |

| Optics |

Standard optical system |

• |

• |

• |

• |

• |

Aqua type Ethanol

can be used as a

dispersing additive.

(0.01 - 3000 μm) |

Standard circulation system |

- |

• |

- |

- |

- |

| Pressurized fill adapter |

- |

- |

- |

• |

- |

| Liter flow |

- |

- |

- |

- |

• |

| Peristaltic pump system |

- |

- |

- |

• |

- |

| Solvent type(0.01 - 3000 μm) |

Standard pump system |

- |

- |

• |

- |

- |

| Accessories |

Fraction cell holder |

• |

• |

• |

• |

• |

| Mini-Flow with ultrasonic unit (0.01 - 1000 μm) |

• |

• |

• |

• |

• |

| Paste cell holder |

• |

• |

• |

• |

• |

| Dry unit (0.1 - 5000 μm) |

• |

• |

• |

• |

• |

| Auto sampler |

- |

• |

• |

• |

• |

| High Concentration Cell |

• |

• |

• |

• |

• |

| Imaging Analysis Unit |

- |

• |

• |

• |

• |

External Dimensions (mm)

Image Credit: HORIBA

Applications

Laser Diffraction Analysis of Lithium-Ion Battery Material

Battery technology is continuously advancing to meet the growing demand for improved power storage. Achieving this enhanced performance necessitates increasingly precise control over the materials employed, including a thorough understanding and management of their physical characteristics, most notably the particle size distribution.

Image Credit: HORIBA

Particle Sizing of Alkaline Battery Materials

Alkaline batteries offer distinct advantages over zinc-carbon batteries, such as higher energy storage capacity, a broad range of operating temperatures, the ability to deliver high currents, and a design that minimizes leakage. Their versatility also makes them suitable for numerous applications. Typically, an alkaline battery comprises a positive electrode made from a blend of manganese oxide and graphite, a negative electrode of zinc, and a potassium hydroxide electrolyte solution.

Image Credit: HORIBA

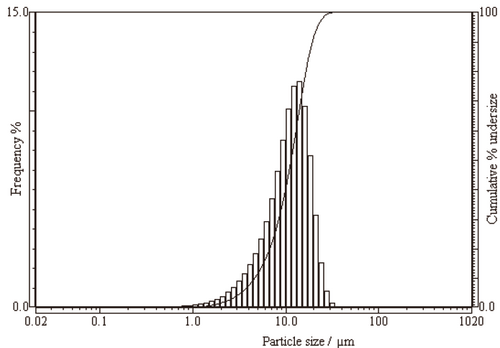

Particle Size Distribution of Black Toner

Toner is a crucial element in electrophotographic printing and copying. For high-quality, high-resolution printed images, synthesized toner particles need specific characteristics, including precise particle size and shape. Using toners with smaller particle sizes has been proposed as an effective way to achieve superior image quality. The particle size distribution analysis of black toner can be optimized using the HORIBA Partica LA-960V2 laser diffraction particle size distribution analyzer.

Image Credit: HORIBA

Calcium Carbonate Particle Sizing for Paint and Coating Applications

For instance, a pigment achieves its optimal color intensity within a specific, narrow particle size range, typically below 1 to 2 microns. Consequently, analyzing the particle size distribution of calcium carbonates is a critical parameter. The HORIBA Partica LA-960V2 Laser Scattering Particle Size Distribution Analyzer investigates the particle size distribution of two distinct calcium carbonate grades.

Image Credit: HORIBA

Particle Analysis of CMP Slurries

The size distribution of abrasive particles in Chemical Mechanical Polishing (CMP) slurries is a critical factor directly influencing key performance indicators. Consequently, particle size analysis serves as a vital measure of CMP slurry effectiveness.

Image Credit: HORIBA

Particle Analysis for Cosmetics

Many cosmetic formulations contain particulate matter or emulsions. Examples include facial powders, moisturizers, and lipsticks. The particle size distribution of these ingredients significantly influences the product's appearance, stability, and protective qualities.

Image Credit: HORIBA

Maximizing Soy Milk Quality Attributes through Particle Size Analysis

Particle size analysis is used to assess the final characteristics of processed soy milk. The resulting particle size data provides a quantifiable measure of soy milk, which can be used to guarantee consistent production and maintain high product quality.

Image Credit: HORIBA

Particle Analysis of Mayonnaise

The crucial role of particle size in the creation of mayonnaise and similar products, as well as how variations in particle size impact the flavor and texture of these alternatives, is analyzed.

Image Credit: HORIBA

Material Characterization of the Next Generation Sugar Substitutes

The significance of the critical particle diameter of dry sugar granules is analyzed, as it directly indicates flowability, dissolution and mixing properties, and overall powder uniformity.

Image Credit: HORIBA

Particle Size Analysis of Piezoelectric Ceramics

Laser diffraction is used as an inspection method for synthesizing piezoelectric ceramics.

Image Credit: HORIBA

Pigment Particle Size and Hiding Power

Laser diffraction offers a quick, user-friendly, and less labor-intensive method for pigment size measurement compared to color strength analysis, providing valuable data for process engineers.

Image Credit: HORIBA

Particle Characterization of Coffee

The HORIBA LA-960 laser diffraction particle size analyzer can measure the full range of coffee ground sizes, offering substantial time and labor savings along with more objective, reliable, and robust measurements.

Image Credit: HORIBA

Particle Size Matters When It Comes to CBD Stability and Bioavailability

The crucial role of tracking particle size and its distribution throughout two distinct processing methods employed to enhance the shelf-life and effectiveness of CBD products is highlighted.

Image Credit: HORIBA

Titanium Dioxide Particle Size

Titanium Dioxide (TiO2), a pigment widely used in paints and various other applications, exhibits performance directly influenced by its particle size. Therefore, measuring and controlling this key property is essential.

Image Credit: HORIBA

Particle Characterization of Nutraceutical Products

Laser diffraction particle size analyzers offer the same advantages in terms of speed, accuracy, and dependability for nutraceutical materials that have made this technique a standard in the pharmaceutical industry.

Image Credit: HORIBA

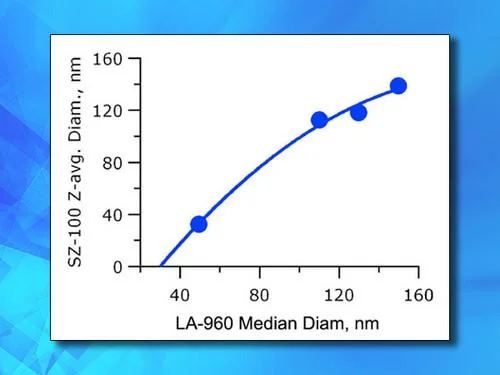

Analysis of Biopolymers with Laser Diffraction

Two experiments demonstrating the capability of laser diffraction to accurately determine the size of both fundamental biopolymer nanoparticles and larger particles that fall outside the measurement range of Dynamic Light Scattering (DLS) are detailed.

Image Credit: HORIBA

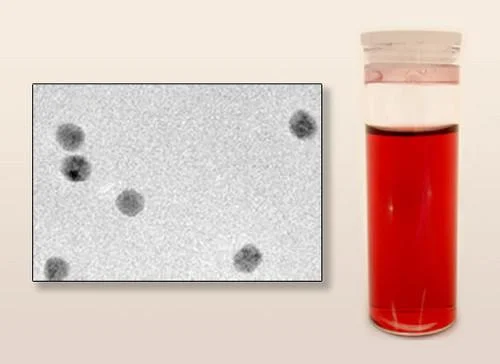

Particle Analysis of Gold Nanoparticles

Nanoparticle gold, a suspension of gold particles smaller than a micron, typically in water, is highly valued by researchers across various fields for its distinctive physical and optical characteristics. Since the particle size distribution directly influences these properties, accurate size analysis is a vital measurement requirement.

Image Credit: HORIBA

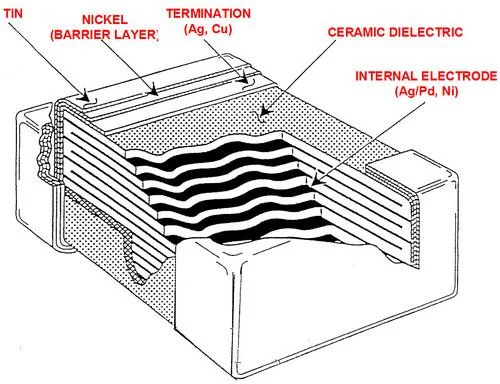

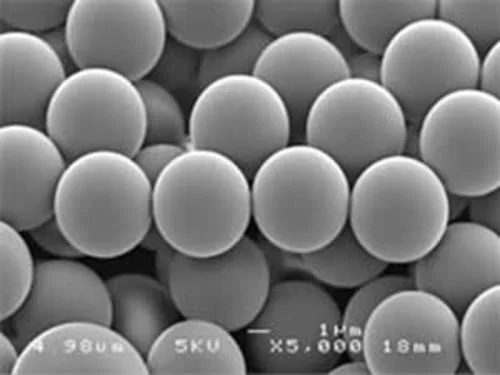

Particle Size of Electronic Ceramic Powders

Particle size analysis is a fundamental aspect of producing electronic materials used in dielectric applications. In all such cases, the particle size distribution significantly affects both the manufacturing process and the final performance of the materials.

Image Credit: HORIBA

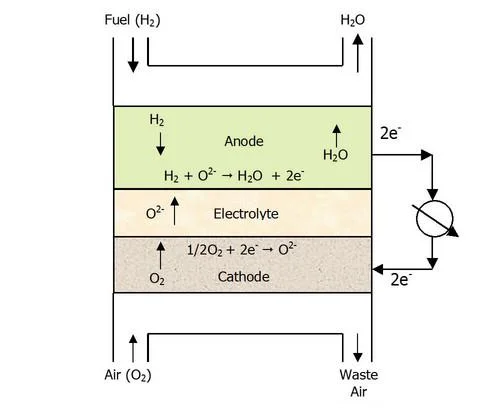

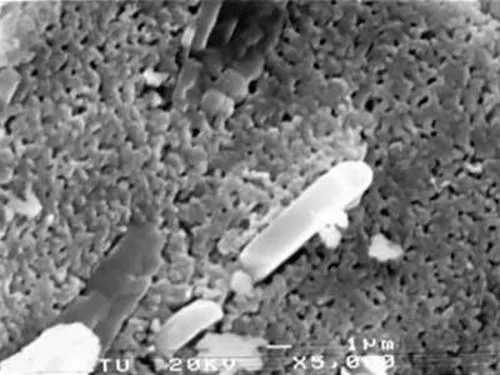

Laser Diffraction Particle Size Analysis of Solid Oxide Fuel Cell Materials

Particle size is a critical property for solid oxide fuel cells, impacting both the characteristics of the powder materials and the overall performance of the fuel cells. Laser diffraction has proven to be an effective technique for monitoring and controlling the particle size of these materials.

Image Credit: HORIBA

Measuring Organic Pigments with Laser Diffraction

Particle size is a key physical attribute of pigments, and laser diffraction is the most widely used method for particle size analysis in the milling process. This technique enables precise control and optimization of several critical final product performance aspects.

Image Credit: HORIBA

Particle Size Analysis of Cement

Accurate measurement and control of cement particle size distribution are essential for achieving the desired product performance and managing production expenses. Laser diffraction is the preferred method for this analysis due to its speed, ease of use, reproducibility, and ability to provide a comprehensive overview of the entire size range.

Image Credit: HORIBA

Laser Diffraction Analysis of Soils and Sediments

Analyzing the particle size of soil and sediment samples is a crucial step in understanding the geological history of a specific region.

Image Credit: HORIBA

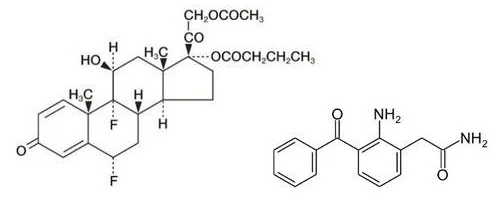

Rapid Particle Size Analysis of Topical Ophthalmic Formulations

In pharmaceuticals, drug particle size and distribution are key critical quality attributes that influence stability, how long a drug stays in the eye (through solution thickness), and how the drug is released for therapeutic effect. Laser diffraction is an effective technique for establishing the fundamental properties of ophthalmic formulations before further studies. To meet the requirements of the FDA, the Partica LA-960V2 Particle Size Analyzer is recommended.

Image Credit: HORIBA

Guide to D-values in Pharmaceutical Particle Characterization

For the pharmaceutical industry, a particle size quantification system tailored to its specific needs is necessary; in this context, D-values, while fundamental, are well-suited.

Image Credit: HORIBA

DLS vs. Diffraction of Flavor Emulsions

The particle size distribution in many flavor emulsions significantly impacts their overall performance, influencing factors like mouthfeel, visual appeal, and how stable the emulsion remains.

Image Credit: HORIBA

Particle Characterization of Powdered Sugar

Quality control is a vital aspect of sugar manufacturing. LA-960V2 quickly analyzes particle separation and the particle size of powdered sugar in its fully de-agglomerated state.

Image Credit: HORIBA

Particle Size Determination of Mineral-Based Sunscreens: A Complex Analytical Application

Mineral-based sunscreens are increasingly popular due to their effective UV ray scattering properties and gentler nature compared to chemical sunscreens, which can cause photo-induced skin irritation. Only two of the 18 sunscreen ingredients approved by the U.S. FDA are minerals.

Zinc oxide is stable under high temperatures and neutral pH, protects against a wide range of UV radiation, and even has mild antibacterial properties. Three commercially available zinc oxide sunscreens were analyzed using the Partica LA-960V2 Laser Diffraction Particle Size Analyzer with a standard 15 mL fraction cell accessory and a magnetic stir bar for this experiment.

Image Credit: HORIBA

Study of Particle Size in the Food Industry: Wheat Flour

Laser diffraction technology, now a leading and highly effective technique in particle size analysis globally, is used to measure the particle size of wheat flour. Compared to the traditional sieve method, laser diffraction offers a faster, non-destructive approach with automated measurement through a straightforward process.

Image Credit: HORIBA

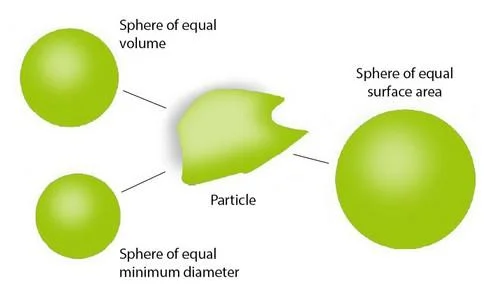

Particle Size and Shape of Abrasives

The effectiveness of an abrasive material hinges on the hardness, size, and shape of its constituent particles. Harder particles are more aggressive in surface modification. Larger particles impart greater impact force, leading to quicker material removal and a coarser surface texture. Particle shape also plays a significant role in the abrasion process.

Image Credit: HORIBA

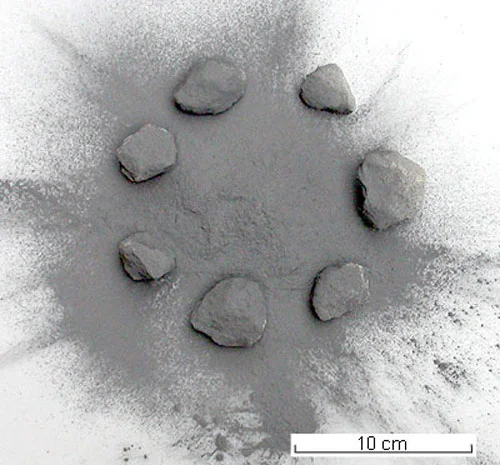

Frac Sand and Proppant Size and Shape

In the oil and gas industry, hydraulic fracturing enhances well flow by injecting proppants with fracturing fluid to keep cracks open. The size, shape, and mechanical strength of these proppants are crucial for maintaining the integrity of the fractures, thus affecting the oil and gas extraction rate.

Image Credit: HORIBA

Metal Powder Size Measurement

Powder metallurgy, a technique for fabricating parts from metal powders produced through atomization, electrolysis, chemical reduction, and comminution, relies heavily on particle characterization. The size distribution and shape of the metal powder particles directly influence the physical properties of the final components.

Image Credit: HORIBA

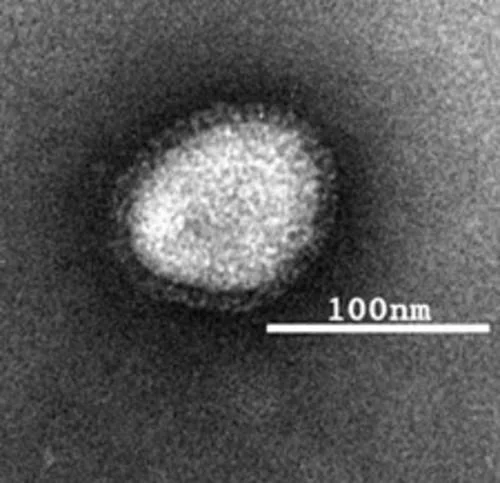

Particle Analysis in Vaccine Manufacturing and Development

In vaccine delivery, size is a critical factor. Nanoparticles smaller than 200 nm generally elicit a stronger immune response compared to microparticles larger than 1 micron.

Image Credit: HORIBA

Particle Size of Paper Chemicals

During paper manufacturing, specific materials are used to control its properties. The particle size distribution of these additives directly affects characteristics such as gloss, brightness, opacity, color bleed, and ink mileage.

Image Credit: HORIBA

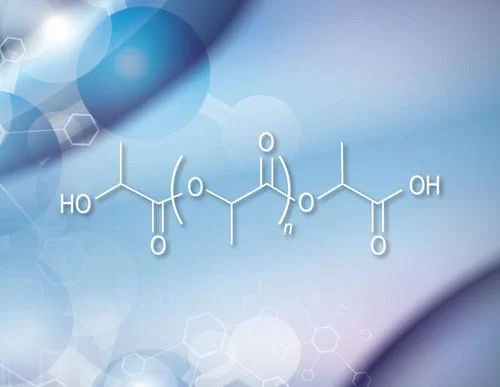

Particle Analysis in Polymers and Plastics

Polymers, large molecules composed of repeating structural units linked by covalent bonds, encompass a wide array of materials, including both synthetic plastics and natural substances like proteins, DNA, cellulose, shellac, and amber.

Image Credit: HORIBA

Particle Analysis for Power Plant Emission Control

For power plants, controlling particle size is essential for meeting environmental regulations while managing capital and operational costs. Investing in particle size analysis helps optimize these costs and improve profit margins.

Image Credit: HORIBA

Protein Aggregation and Size Analysis

The study of protein aggregation involves diverse interactions and mechanisms. The LA-960 laser diffraction particle size analyzer is uniquely capable of measuring particles ranging from 10 nm to 5 mm, allowing accurate detection of aggregates and, in some instances, the size of the individual proteins.

Particle Analysis of Road Materials

Asphalt emulsions, consisting of tiny asphalt droplets dispersed in water with an emulsifier, have stability and application performance critically dependent on the size of these droplets.

Image Credit: HORIBA

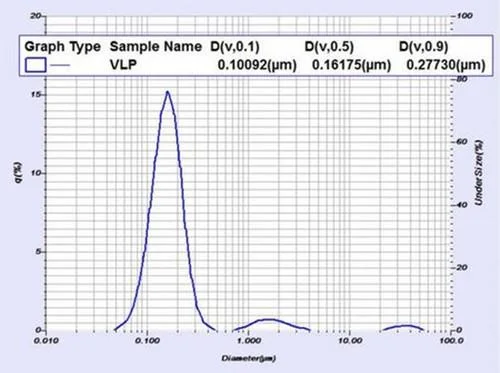

Viruses and Virus-Like Particles

A virus particle is composed of genetic material (DNA or RNA), a protective protein coat, and sometimes a lipid envelope surrounding the coat when outside a host cell.

Image Credit: HORIBA

Comparison of Results Between Laser Diffraction and Image Analysis

Laser diffraction is a widely used technique for characterizing particles. When combined with an image analysis unit, it enables real-time comparison of standard size parameters (D10, D50, D90) alongside information about particle shape and dispersion, highlighting the value of this complementary approach.

Image Credit: HORIBA

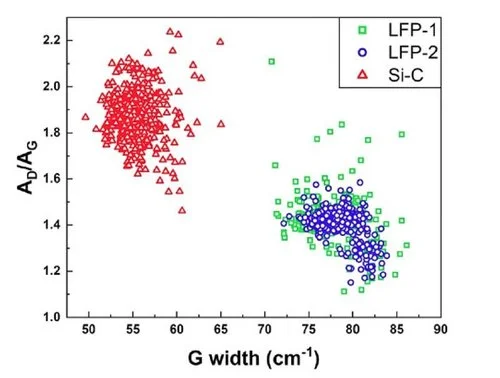

Characterizing Battery Materials by Particle Size and Shape Analysis and Raman Spectroscopy

As the demands on electric vehicles and portable devices continue to grow, there is an increasing need for high-performance batteries and advanced methods to monitor battery materials' physical and chemical properties. Among the emerging materials gaining traction in rechargeable lithium-ion batteries are lithium iron phosphate (LFP) for cathodes and carbon-coated silicon (Si@C) for anodes.

Image Credit: HORIBA