The EMIA-Step Carbon/Sulfur Analyzer provides extremely sensitive and accurate analysis through the use of a tubular electric resistance heating furnace. Its variable heating temperature (up to 1450 °C) feature enables whole amount analysis and quantitative analysis by separating it by temperature or humidity.

HORIBA provides the EMIA-Pro (Entry model) and EMIA-Expert (Flagship High-Accuracy Model) for samples that are challenging to burn, such as ceramics, Ti alloys, etc.

Image Credit: HORIBA

Features

Greater Accuracy

Proven NDIR Gas Detection Technology

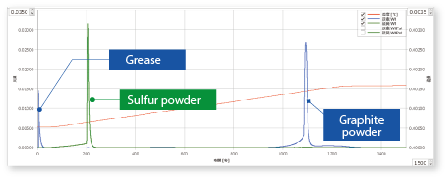

The EMIA-Step Carbon/Sulfur Analyzer uses infrared technology to measure carbon and sulfur levels after combustion in an electric resistance furnace. HORIBA can detect sulfur ranging from 0.0004 to 1.0% (m/m) and carbon ranging from 0.0003 to 6.0% (m/m) because of its well-known Non-Dispersive Infrared (NDIR) measurement capabilities.

The analyzer can be utilized with a variety of inorganic materials, such as steel, cokes, catalysts, non-ferrous alloys like aluminum, and lithium-ion battery materials. It also has a special CO detector.

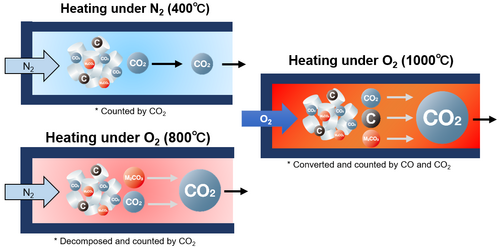

Temperature Control Function

The analyzer's combustion furnace features a unique sealed system that enables the efficient combustion of flame-retardant materials via high-pressure oxygenation. The system has good temperature stability, resulting in constant operation at both low and high temperatures.

This broadens the spectrum of applications to samples containing chemicals that disintegrate quickly and burn at low temperatures. The breakdown combustion of organic and inorganic substances is plainly seen.

Temperature rise control from 300 °C to 900 °C. Image Credit: HORIBA

Improved Measurement and Maintenance Efficiency

New Dust-Filter Provides Easy Maintenance Capability

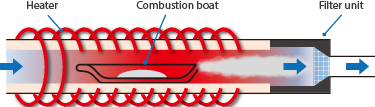

The EMIA-Step incorporates a dust-filter mechanism that has been proven efficient in high-frequency induction heating models. The filter unit catches dust produced by high-temperature combustion and prevents it from clinging to the pipes after the furnace. This decreases dust adsorption of CO2 and SO2 gases, allowing for more accurate and sensitive readings.

Schematic of tubular electric resistance heating furnace. Image Credit: HORIBA

High Throughput

The EMIA Series can complete one measurement cycle (measurement-display result-cleaning) in 70 seconds (or around 50 samples per hour).

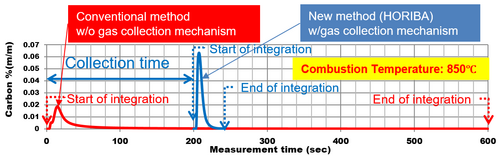

Gas Collection Mode

The unique furnace has a closed structure allowing efficient combustion under high-pressure oxygen and high melting point materials. This unique furnace design enables Gas Collection analysis, which involves capturing small volumes of gases within the furnace and then transferring them to the detector for analysis.

More Intuitive Software for Easy Operation

Advanced Operation Software

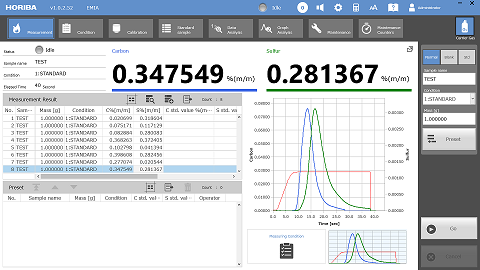

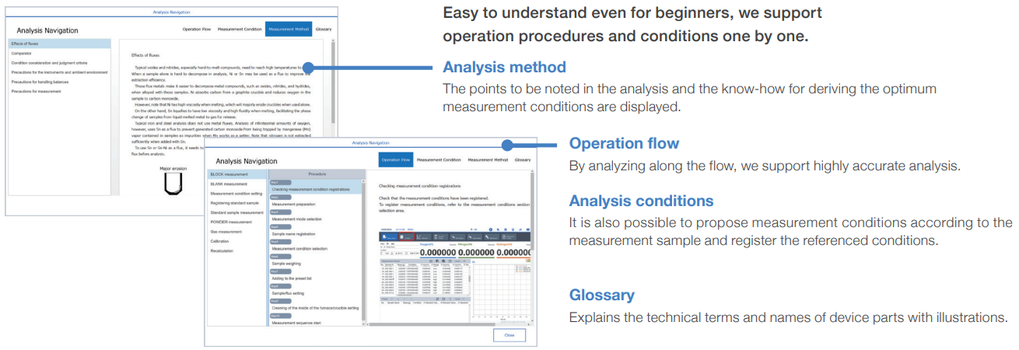

The EMIA Series comes with its own proprietary operating software, which was built with ease of use in mind. The software optimizes layout, operating menus, and functionalities for improved usability.

Image Credit: HORIBA

Enhanced Operator Assistance

The software also contains a self-diagnostic monitoring feature that assesses the status of connected devices, an alarm function, and three navigators that indicate the best conditions for samples, troubleshoot issues, and notify users to undertake maintenance. These features enhance daily operations and ensure efficient analysis.

Compliance with ISO/ASTM Standards

Source: HORIBA

| Test Methods |

Title |

Carbon |

Sulfur |

| ISO/TR 15349-1:1998 |

UNALLOYED STEEL — DETERMINATION OF LOW CARBON CONTENT — PART 1: INFRARED ABSORPTION METHOD AFTER COMBUSTION IN AN ELECTRIC RESISTANCE FURNACE (BY PEAK SEPARATION) |

✓ |

|

| ISO/TR 15349-3:1998 |

Unalloyed steel — Determination of low carbon content — Part 3: Infrared absorption method after combustion in an electric resistance furnace (with preheating) |

✓ |

|

| ASTM E 1019-18 |

Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques |

✓ |

|

| ASTM E 1587-17 |

Standard Test Methods for Chemical Analysis of Refined Nickel |

✓ |

✓ |

| ASTM E 1941-10 (2016) |

Standard Test Method for Determination of Carbon in Refractory and Reactive Metals and Their Alloys by Combustion Analysis |

✓ |

|

| ASTM E 1915-20 |

Standard Test Methods for Analysis of Metal Bearing Ores and Related Materials for Carbon, Sulfur, and Acid-Base Characteristics |

✓ |

|

| ASTM E 1552-16e |

Standard Test Method for Sulfur in Petroleum Products by High Temperature Combustion and Infrared (IR) Detection or Thermal Conductivity Detection (TCD) |

|

✓ |

| ASTM E 4239-18e1 |

Standard Test Method for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion |

|

✓ |

| ASTM E 5016-16 |

Standard Test Method for Total Sulfur in Coal and Coke Combustion Residues Using a High-Temperature Tube Furnace Combustion Method with Infrared Absorption |

|

✓ |

| ASTM E 1619-16a |

Standard Test Methods for Carbon Black—Sulfur Content |

|

✓ |

Specifications

Source: HORIBA

| Detection method |

NDIR (Non-Dispersive InfraRed) |

| Required sample amount |

1.00 ± 0.10 g |

| Minimum reading |

0.000001% (m/m) for both Carbon and Sulfur |

| Carbon |

Measurement range |

0.0003 〜 6.0% (m/m) |

| Accuracy (Repeatability) |

σn-1 ≦ 0.00015% (m/m) or RSD ≦ 0.75% |

| Sulfur |

Measurement range |

0.0004 〜 1.0%(m/m) |

| Accuracy (Repeatability) |

σn-1 ≦ 0.00020% (m/m) or RSD ≦ 2.00% |

| Setting temperature range |

0 (room temperature) - 1450 ℃ |

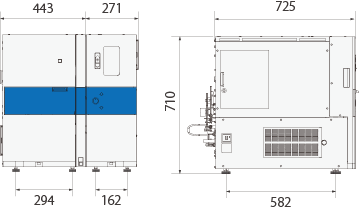

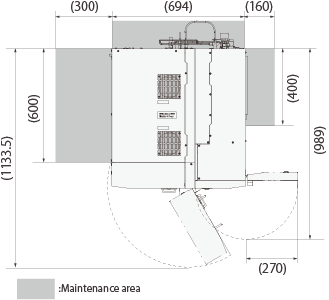

| Dimensions [W x D x H] |

Combustion unit: 443 × 725 × 710 mm

Measurement unit : 271 × 725 × 710 mm |

| Mass |

Combustion unit: 77 kg, Measurement unit: 53 kg |

| Power |

200/220/240 V, 5 kVA *Excluding peripheral devices |

| Carrier gas |

Oxygen: Purity 99.5%, Pressure: 0.30 〜 0.33 MPa |

| Operation gas |

Nitrogen: Purity 99.5%, Pressure: 0.35 〜 0.38 MPa

*Dry air excluding moisture and oil content can be used as the operation gas only for the standard model |

| Data processing and operation |

PC with Windows® 10 |

| User interface |

Touch panel/Keyboard/Mouse |

* Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

Image Credit: HORIBA

Applications

Separation and Quantitative Analysis of Carbon and Carbonates in Surface Material of Asteroids

Image Credit: HORIBA

Carbon, as a constituent of matter, is broadly divided into organic and inorganic carbon. Organic carbon refers to carbon found in organic products, whereas inorganic carbon includes elemental carbon and carbonate carbon.

The presence of carbonate in a sample collected from an unknown planet suggests the presence of water on that planet. Therefore, the determination of carbonate is very significant in space science.

Quantitative Analysis of Carbon in Polysilicon

Image Credit: HORIBA

Polysilicon, the basic material for silicon wafers, requires precise control over carbon concentration, which influences conductivity. As better-quality silicon wafers are required, it is critical to understand the amount of carbon in the polysilicon used as a material.

However, some carbon is present as carbonate, while others are attached as CO2, making it impossible to discriminate between the two and evaluate the exceedingly little amount of carbon.

Quantitative Analysis of Carbon Contained in Bone Substitute Material

Image Credit: HORIBA

In orthopedic, clinical, and surgical fields, various alternatives to natural bone materials have been studied and developed. Recently, there has been growing interest in bone prosthetic materials that closely mimic the composition of living bone. As a result, the demand for reliable methods to measure carbon content in these materials has significantly increased.

The EMIA series offers a flexible and precise solution capable of measuring a wide range of sample types. It delivers accurate results with excellent reproducibility, ideal for supporting both research and clinical applications.

Analysis of Free Carbon in SiC

Image Credit: HORIBA

Thanks to its exceptional hardness and heat resistance, silicon carbide (SiC) is widely used as an abrasive and refractory material. However, free carbon is often introduced during its production, an element known to negatively impact the strength of sintered products. For this reason, accurately quantifying the free carbon content is essential.

Traditionally, this has been done using a wet chemical method involving hydrofluoric acid in accordance with JIS standards. While effective, this approach is hazardous and requires more than three days for sample preparation, posing safety risks and significant delays.

Thanks to HORIBA's new gas collection mechanism (patent pending), the EMIA-Step allows for safe, efficient analysis of free carbon:

- Fast results with minimal sample prep

- Reliable performance even with materials like free carbon that burn slowly

This solution offers a much safer and more efficient alternative to traditional methods, helping users meet safety and productivity demands.

Measurement of Sulfur in Rubber

Sulfur is added to natural rubber to create plastic products. However, measuring the sulfur content of the rubber is critical for determining the chemical and mechanical qualities of the finished product.

Measurement of Carbon in Ferrosilicon

Ferrosilicon is used as a deoxidant and an alloying ingredient in steels requiring a low carbon content. Ferrosilicon contains little carbon, which reduces electrical conductivity and magnetostriction in electrical steels.

Quality Assurance for the Analysis of Steel by Gas Component Analysis

Sample Preparation and Sampling Methods for the Gas Analysis of Steel

Measurement of Carbon and Sulfur in Copper

Copper is a reddish metal that is malleable, ductile, and an excellent thermal and electrical conductor. It is commonly used in electrical wire, water piping, and corrosion-resistant equipment, whether pure or in alloys such as brass and bronze. Carbon and sulfur are considered impurities; hence, it is critical to measure and verify Copper purity.

Measurement of Carbon and Sulfur in Titanium Oxide

Titanium oxide is largely utilized in the manufacture of paints and plastics, but it is also used in paper, printing inks, cosmetics, textiles, and food products.

Carbon Analysis: Organic and Inorganic Carbon in Soils

Image Credit: HORIBA

It helps determine organic and inorganic carbon in soils and how to prepare samples to remove inorganic carbon (carbonates) from soils.