The NEW SA-9650 line of surface area analyzers offers ease, impressive measurement speed, and a cheap cost-per-analysis for a wide range of materials.

Users can now do exceptionally fast single or multi-point surface area measurements with the push of a button, acquiring gas adsorption and desorption data using the robust, time-proven flowing gas (dynamic) technique. Once acquired, the information is utilized to compute the total surface area using the BET method.

The SA-9650, housed in a redesigned cabinet, is designed to enable secure and convenient access to the prep and test stations. The analyzer can be controlled with the built-in microcomputer, keyboard, and LCD display, or with any Windows PC via a USB connection. The new electronics and hardware have been enhanced and now bear the CE marking.

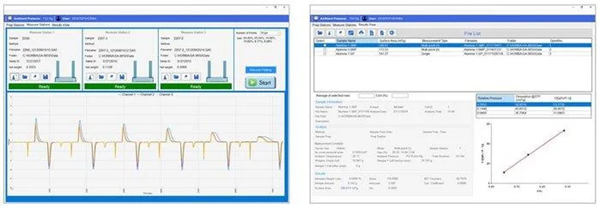

The new, upgraded software enables the user to produce reusable Method files with improved, intuitive graphics by following guided, on-screen preparatory guidance. Reporting enhancements include results averaging, overlays, automatic PDF reports, and raw data exports.

There are single and three-station variants available, with the ability to measure up to three surface areas at once. Depending on the sample, measurements can take 15 minutes for single-point and 45 minutes for multi-point. The results can be shown immediately upon measurement.

Image Credit: HORIBA

Image Credit: HORIBA

Features

Surface Area Analysis

A material's surface area is often as significant as its chemical qualities, and it can influence many elements of its performance. This is because the material's interface determines how solids behave in the presence of other components, such as gases, liquids, or solids.

This impacts things like:

- The shelf life, stability, dissolution, and efficacy of medicinal powders and tablets

- The rheological characteristics and concealing abilities of coatings, paints, and pigments

- The ability of materials such as catalysts, adsorbents, filtration materials, and air separation products to react in the designed application

- Refine oil products

- Purify the air, separate gases, or eliminate toxic byproducts

- The production and performance of ceramics utilized in a variety of applications, including dinner plates, dental implants, and electronics

- Powder surface area affects electrode performance, fabrication process, electrolyte interaction, and electrochemical stability in a variety of batteries

Measuring various materials' specific surface area (surface area per unit mass) via gas adsorption is a standard technique in materials science, chemistry, and many industries.

HORIBA's SA-9650 Series Analyzers Offer the Perfect Solution to a Myriad of Surface Area Analysis Needs

Automatic Analysis

Starting an analysis is as simple as pressing a single button. The full analysis is done without additional intervention, avoiding the manual steps required by many similar analyzers. Once the analysis begins, calibration takes place, and the liquid nitrogen Dewars are automatically raised and lowered using computer control. After the analysis is completed, data is automatically generated and made available.

Compact, All-in-One

The redesigned cabinet of the SA-9650 enables front-facing access to all operational touch points, eliminating the need for side access. Unlike many other analyzers, there is no requirement for separate analysis and preparation instruments. Use the built-in computer and keyboard to maximize space savings in the lab.

Safe and Secure

Both the Prep and Test Stations are secured by clear safety doors that must be properly closed before use. Heat will be turned off at the Prep station, and the Test station Dewar tray will not move if the station doors are opened, keeping personnel safe.

No User Calibration Required

To achieve repeated accuracy, the SA-9650 automatically calibrates before each measurement. From then, the SA-9650 technology eliminates variables that would otherwise be introduced by operator participation.

No Freespace or Void Analysis Required

The flowing gas or dynamic approach does not require additional time to measure the sample tube volume or free space. Furthermore, no sample tube volume measurements or calibrations are necessary.

Lowest Cost of Ownership

Mass flow controllers in multipoint variants of the SA-9650 series automatically generate the required nitrogen and helium mixtures for multi-point BET surface area analysis. This reduces the overall cost of ownership by eliminating the need to purchase costly gas mixtures or external gas mixer devices. Compared to more complicated, static volumetric technology, the straightforward design ensures low service costs.

Detector Protection

In the event of a missing or broken sample cell, an automated measurement station bypass loop controlled by a cell detector switch ensures that the gas mixture flows through the Thermal Conductivity Detector without interruption.

Electronic Valves

Reliable electronic valves eliminate the requirement for a pressurized air or gas source to activate valves throughout the measurement process, minimizing the overall cost of ownership.

Improved Gas Handling

Manifold layout and valve selection are carefully designed to produce more steady, balanced flow, improve repeatability, minimize maintenance costs, and facilitate operation.

Robust Dewar Elevator System

A tough mechanical design results in smoother and more reliable movement of the Dewar tray, which lifts and lowers the LN2 Dewar.

Newly Designed Software

Image Credit: HORIBA

Users can easily operate the analyzer by following a simple, three-step procedure:

- Type in the sample name

- Select the measurement type

- Click “Start” to begin measurement

View in real-time to see the auto-calibration, adsorption, and desorption. A full surface area report will be completed in minutes.

Flexibility

Built-in functions enable system optimization for various sample kinds.

- Gas concentrations in mixed gases can be accurately regulated to get results identical to the multipoint approach

- A large range of sample cells are available, allowing measurements to be performed on a variety of sample types

Use the upgraded SA-9650 software to control the instrument via USB connection to a Windows PC, or users can run the analyzer using the built-in computer with an LCD and keyboard.

High Throughput

Each SA-9650 model contains three sample preparation stations to increase workflow. Depending on the sample, users can finish a measurement procedure in 15 minutes for single points or 45 minutes for multipoints.

Specifications

BET Surface Area Measurement Range

- Total Surface Area: 0.1 to 50 m2

- Specific Surface Area: Approximately 0.01 – 2000 m2/g

- Much more sensitive to low surface area samples than volumetric analyzers, allowing samples weighing less than 1 g and measuring as little as 0.1 square meters in the sample cell

Accuracy and Precision

- Reproducibility is higher than 1% COV

- Most samples have an average accuracy of 5%

The SA-9650 Series includes a complete array of high-quality, high-performance BET Surface Area Analyzers to satisfy the requirements of any research or quality assurance laboratory. The SA-9650 Series analyzers contain the following:

- SA-9650-1SP: One sample analysis station, three sample preparation stations

- SA-9650-1MP: One sample analysis station, three sample preparation stations, MFC gas mixture control, and multi-point analysis

- SA-9650-3SP: Three sample analysis stations, three sample preparation stations

- SA-9650-3MP: Three sample analysis stations, three sample preparation stations, MFC gas mixture control, and multi-point analysis

Source: HORIBA

| |

SA-9650-1SP |

SA-9650-1MP |

SA-9650-3SP |

SA-9650-3MP |

| Single-Point |

Yes |

Yes |

Yes |

Yes |

| Multi-Point |

No |

Yes |

No |

Yes |

| Analysis Stations |

1 |

1 |

3 |

3 |

| Preparation Stations |

3 |

3 |

3 |

3 |

| Range |

0.10 to > 2000 square meters per gram |

| Repeatability |

<1% relative standard deviation (RSD) |

| Power Requirements |

100, 120, 220 or 240 volts AC, 50/60 Hz

Maximum peak power 200 Watts |

| Weight |

59 lbs

(26.76 kg) |

62 lbs

(28.12 kg) |

63 lbs

(28.58 kg) |

66 lbs

(29.94 kg) |

| Dimensions |

26” H x 25” W x 20” D (66.1 cm H x 63.5 cm W x 50.8 cm D) |

| Compliance |

(CE) Meets EU safety, health and environmental protection requirements. |

SA-9650 models available in single station (left) or three stations (right). Image Credit: HORIBA

Applications

Surface Area of Graphite

Image Credit: HORIBA

Graphite's features originate from its hexagonal lattice structure. It comprises carbon atoms organized in layers, each consisting of interconnected hexagonal rings. These layers move readily past one another, giving graphite its distinctive lubricity.

Surface Area of Aluminum Oxide

Image Credit: HORIBA

Aluminum oxide, or alumina, is a compound made of aluminum and oxygen. It is one of the most plentiful minerals in the Earth's crust, and its distinctive qualities make it useful in a variety of applications.

Surface Area of Hydroxyapatite

Image Credit: HORIBA

Hydroxyapatite is a natural mineral type of calcium apatite. It is the major mineral component of vertebrate bones and teeth, as well as other tissues such as dentin and enamel.

Surface Area of Calcium Carbonate

Image Credit: HORIBA

Calcium carbonate's surface area influences its reactivity, efficacy, and performance in various applications. A bigger surface area allows for more interactions with other substances, such as acids or chemicals.

Surface Area of Bentonite

Image Credit: HORIBA

The surface area of bentonite is crucial because it considerably impacts its reactivity, adsorption capacity, and effectiveness in diverse applications. Bentonite clay's unique layered structure and microscopic particle size allow for a large surface area.

Surface Area of Kaolinite

Image Credit: HORIBA

Kaolinite, a soft mineral created by the chemical weathering of aluminum silicate minerals like feldspar, is one of the most prevalent and extensively dispersed clay minerals. Kaolinite is ground to achieve the desired surface areas and particle sizes, which are essential for its use in a variety of applications.

Surface Area of Calcium Hydroxide

Image Credit: HORIBA

Calcium hydroxide, often known as slaked lime or hydrated lime, is a powder commonly used in the chemical industry. Calcium hydroxide's surface area influences the way and rate at which it reacts in chemical reactions.