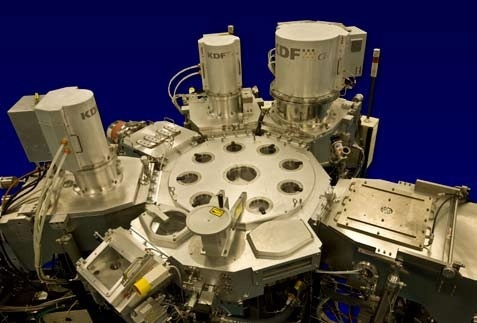

Following years of development and testing, KDF is pleased to announce the launching of its new cluster tool line, Ci for Cluster Intelligence.

The Ci tools will be available in four and eight-sided configurations, with both system types featuring Brooks Marathon series vacuum handlers.

Depending on the application, the system is configured to meet specific process requirements. The Ci is designed to serve a range of niche markets, including compound semiconductors, DWDM components, MEMS, MOEMS, sensors, nanotechnology, and advanced packaging, supporting substrate sizes up to 200 mm. The KDF tool offers a cost-effective solution for entering or maintaining high-yield, high-throughput production environments.

Years of Experience

With over 35 years of manufacturing and engineering expertise, KDF is confident that this tool will outperform others in its class, without the high cost associated with other OEMs. It can operate with custom wafer carriers if needed and is configurable for 4- to 8-inch wafers, based on customer specifications.

The Ci tools feature a range of modules designed to populate every facet of the central handler. The Ci S Module, or Sputter Module, incorporates KDF’s uniquely designed rotating circular magnetron cathode assembly, delivering high sputter rates, excellent material utilization, and superior uniformity.

This module can also be equipped with a stepper-driven rotating anode platen to maximize substrate uniformity. For advanced applications, the platen can be fitted with another KDF exclusive: a PBN/PG backside heater element capable of reaching temperatures up to 1000 °C.

In Line with the Process

KDF develops and manufactures the industry's most intelligent cluster platforms. At the lowest cost of ownership in the industry, KDF's systems are all designed to satisfy high throughput requirements and adaptability across multiple industries.

- Optical communications

- Medical devices

- Mainstream silicon

- Emerging materials

Intelligent cluster solutions from KDF are simpler:

- Automation

- Tool uptime

- Reliability

- Environmental health and safety benefits

- Film uniformity

- Throughput run to run

- Process stability

- ROI

KDF meets customer needs by rapidly developing tailored solutions, building on its core strengths. Its tools can be specifically modified to boost throughput, ROI, or time to market, allowing you to configure the cluster's sputtering system that fits your exact requirements.

Image Credit: Kurt J. Lesker Company

Ci S Sputter Module

- CTI 8F Cryo pump

- ACR, Auto Pump, Auto Vent

- Rockwell PLC system with integrated brick pc

- MKS Quattro Combo gauges (485 interface)

- KDF Cryo temp readouts with setpoints

- Plasma view port assembly

- 24 VDC water ON/OFF valving along with safety water leak detectors

- Full host of interlocks for system and personnel safety

- Ethernet IP run air manifold

- Back side lift pin pedestal design for wafer entry and extraction

- 12 inch Rotating Circular Magnetron Cathode RF or DC operation

- SS chamber assembly with Quick change shields

- SS rough and regen valves Nupro vent valves

- Water Cooled chamber top plate

- Automated Top Plate hoist

- MKS Pendulum Throttling Gate valve

- Up or downstream gas capable

- AE 10 kW DC supply

- Automatic shutter for Pre Sputter mode, or target clean

- MKS single gas MFC 200sccm

- MKS 627 100 mt manometer

Options

- AE Pinnacle Plus DC Power supply

- AE Dressler 3 kW RF option (replaces DC supply)

- A heated platen anode pedestal that can withstand temperatures as high as 1000 °C

- Rotating anode 0 to 60 rpm

- CTI Onboards Cryo pumps

- RF bias operation

- Al shield kits for Ti W dep

- MKS second and third gas channels

Ci S Tri-Sput Module

- Each of the three 3-inch sputter guns has its own RF600 W power supply

- SS chamber assembly with Quick change shields

- SS rough and regen valves Nupro vent valves

- Water Cooled chamber top plate

- Complete set of interlocks for system and worker safety

- MKS Pendulum Throttling Gate valve

- Up or downstream gas capable

- Automatic shutter for Pre Sputter mode, or target clean

- MKS single gas MFC 200 sccm

- MKS 627 100 mt manometer

- CTI 8F Cryo pump

- ACR, Auto Pump, Auto Vent

- Rockwell PLC system with integrated brick pc

- MKS Quattro Combo gauges (485 interface)

- KDF Cryo temp readouts with setpoints

- Plasma view port assembly

- Wafer entry and extraction using a lift pin pedestal configuration on the back side

- Ethernet IP run air manifold

- 24 VDC water ON/OFF valving along with safety water leak detectors

- Full host of interlocks for system and personnel safety

- Wafer entry and extraction using a lift pin pedestal configuration on the back side

Options

- CTI Onboards Cryo pumps

- RF bias operation

- Al shield kits for Ti W dep

- MKS second and third gas channels

- AE Pinnacle Plus DC Power supply

- Heated platen anode pedestal for temperatures up to 1000 °C

- Rotating anode 0 to 60 rpm

Ci D Degas Module

- Aluminum chamber with a small, compact design

- Gas-assisted top plate for manual lift

- CTI 8 F cryo pump

- SS gate valve

- SS rough valves and regen, Nupro vent valves

- Ethernet IP run air manifold

- MKS 999 RS485 combo gauge

- The heated PBN/PG backside heater element can reach temperatures of up to 1000 °C

- Heater control using PWM phase control with the PLC executing the PID

- Back side edge lift pin pedestal design for wafer entry and extraction

Ci E Etch Module

- Advanced Energy 3 kW RF Power supply

- Automatic Top Plate hoist

- Back side edge lift pin pedestal design for wafer entry and extraction

- CTI inline water pump, before the turbo

- Ethernet IP run air manifold

- Full host of interlocks for system and personnel safety

- KDF Exclusive design BMC (Band magnetron cathode) etch cathode offers high rate low damage ion bombardment of the substrate

- MKS Pendulum throttling gate valve

- MKS three gas MFC’s provide three channels of gas flow

- Nupro vent valves

- Osaka Mag-lev Turbo pump, with dedicated dry pump back up

- Rockwell PLC system with integrated brick PC

- SS chamber

- SS rough valves and foreline

- Water Cooled chamber top plate and counter magnet assembly

- 24 VDC water ON/OFF valving along with safety water leak detectors

Options

- Heated platen anode pedestal for temperatures up to 1000 degrees C

- Rotating anode 0 to 60 rpm

Ci Load and Unload Centers

KDF provides a single wafer entry load lock, which is a tiny aluminum chamber that is turbo-pumped for basic R&D operations. KDF will also configure the tool with a single or dual Brooks VCE(s) to enable the system's quick wafer load and unload function.