The 974i Series includes dual load lock, in-line, sputter-down batch systems, available with an optional high-vacuum load lock and a choice of three or four target positions.

974i Series:

Designed to meet today’s stringent production requirements, the 974i Series offers process flexibility typically found in R&D systems. It surpasses the criteria for thin film deposition in application-critical devices and other applications requiring the highest level of uniformity.

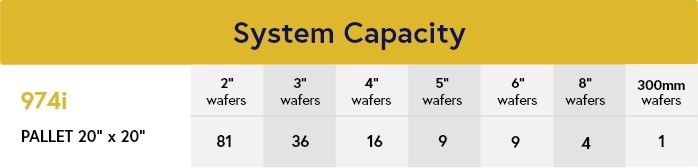

- 20” x 20” substrate area.

- Capacity to process up to one Gen 2.5 substrate on the pallet.

- Capacity to process dimensional substrates up to 2” thick.

- High-rate DC magnetron sputtering and single / multiple-pass deposition features.

- High vacuum loadlock with quartz heater lamps for efficient degassing of substrates.

- Horizontal cathode and substrate orientation for gentle substrate fixturing and varied substrate sizes.

- Throughput for 200mm wafer metallurgy is increased four times over that of a 900i Series system.

- Optional planetary substrate pallet for unsurpassed film uniformity.

- Optional integrated RGA for process and fault monitoring of gas peaks along with integrated hi vac step.

- Optional load lock upgrade: increase load lock capacity from dual (2) to five (5) pallet stack.

The 974i Series systems can be equipped with KDF’s exclusive Enhanced Rotary Planetary Pallet (ERPP™), which significantly improves wafer uniformity. When paired with KDF’s cathodes, this pallet option delivers uniformities better than ±1 % across the pallet and repeatability better than 0.5 % between runs for dielectrics like SiO2 and TiO2 - compared to the traditional ±15–20 % uniformity range for these materials.

For specialized applications, the 974i Series also offers KDF’s Focest Cathode™, originally developed for high-aspect ratio deep trench fills. This cathode enhances uniformity, deposition rate, and material utilization.

The 974i is optimized for contact metallurgy processing, offering pure metal target deposition and easy wafer-to-pallet loading for sputter-down applications.

It’s also well-suited for producing application-critical thin films used in hybrid circuits for defense, aerospace, and space telecommunications. These applications demand a repeatable, high-throughput process to produce consistently uniform films.

Designed for processing GaAs and other compound semiconductors, the 974i is a four-target batch sputtering tool that supports both frontside and backside deposition, maximizing material utilization and overall productivity.

The 974i features KDF’s latest cathode designs, now extended to 24.5 inches, to improve uniformity across the entire pallet. Cathode options include Planar™, Inset™, and RF/DC LMM™ configurations.

974i Series Vacuum Specifications:

- 974i Series Vacuum SpecificationsChamber ultimate ≤1 × 10-7 torr

- Chamber leak rate, 20 minutes to 1 × 10-4 torr

- High vacuum dome ultimate ≤1 × 10-7 torr

- High vacuum dome leak rate, 15 minutes to 1 × 10-4 torr

- Pump down from atmosphere 110 minutes or less to 1 × 10-6 torr or 2 × 10-7 torr overnight

Image Credit: Kurt J. Lesker

974i Series System Hardware Features:

- 20 kW low stored energy DC power supplies (Advanced Energy). Optional Pinnacle Plus power supplies.

- Complies with NFPA79 guidelines.

- Consult the factory for an extensive list of standard options.

- Fully automated self-locking top plate support system.

- Integrated throttling SS VAT valve, allowing for upstream or downstream pressure control.

- Loadlock linear sensor – computer controller positioning system for increased loadlock accuracy and more limited fail-safe.

- Low pressure hydraulics system for safety and smooth operation.

- MKS multi-component “Smart” 390 and 925 gauges for integrated vacuum measurements.

- Optional 3kW/RF solid state power supply (Advanced Energy).

- Process gas control with up to four gas controllers; feedback-controlled capacitance manometer; master/slave gas selectability; and gas ratio control.

- Stepper motor pallet carrier drive with optical encoder providing accurate programmable pallet carrier positioning, scan velocity profiling available.

974i Series Computer Sub-System:

- Context sensitive recipe manager running out of Microsoft® SQL database.

- Distributed Rockwell Control System utilizing DeviceNet and Ethernet IP field bus technologies.

- Fully integrated package for real-time data display, data logging fully compatible with Excel™, Lotus™ and other Windows™ applications, report generation, remote interface and printing.

- Maintenance test suite with full diagnostic and manual process control capability.

- Optional connectivity to SECS/GEM communication and Windows™ applications through an OPC server interface.

- Service-friendly, fully enclosed electronic cabinet.

- Windows™ 10-based real-time GUI environment, coupled with 24” LCD touchscreen monitor mounted on an umbilicaled mobile HI cart.

974i Series Basic Facility Requirements:

- Process Gas: 25 PSIG 99.999 %

- Pure Gas: Dry N2

- Power: 208 VAC, 3-phase, 100 Amps

- Water: 6.5 GPM, 70 PSIG min., 10 °C – 24 °C

- Compressed Air: 85 - 100 PSIG

Image Credit: Kurt J. Lesker

Image Credit: Kurt J. Lesker

In line with the Process

KDF develops and manufactures the industry's most dependable in-line sputtering tools. At the lowest cost of ownership in the industry, KDF's systems are all designed to satisfy high throughput requirements and adaptability across multiple industries.

- Mainstream silicon

- Emerging materials

- Flat panel displays

- Optical communications

- Medical devices

Compared to cluster tools, KDF's in-line batch sputtering systems are simpler to operate and maintain on all platforms. Users of KDF's solutions benefit from increased:

- Tool uptime

- Reliability

- Environmental health and safety benefits

- Film uniformity

- Throughput run to run

- Process stability

- ROI

- Automation

KDF meets customer needs by rapidly developing tailored solutions, leveraging its core competencies. Its tools can be specifically engineered to improve throughput, ROI, or time to market. All existing KDF equipment is fully supported with available upgrades and retrofits. Additionally, as the OEM for MRC batch systems, KDF provides comprehensive parts and service support for all