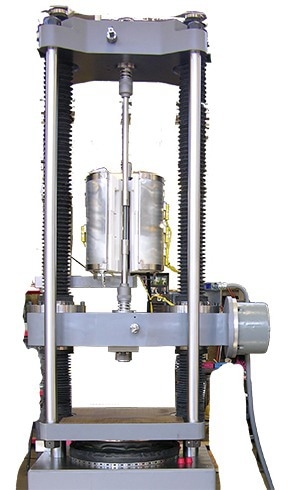

The 600SL model is engineered for evaluating the tension, compression, flexure, and shear strength of both materials and assemblies. Its robust construction - built using high-grade materials - supports dependable performance, user-friendly operation, and long-term durability.

Tinius Olsen’s hydraulic testing systems have earned global recognition for their accuracy, reliability, and adaptability. With thousands of machines actively used across the world, the SL series continues to represent the industry benchmark for hydraulically powered universal testing equipment.

Features and Benefits

- This system supports a wide range of tests - including shear, transverse, compression, and tension - at forces up to 600 kN (120,000 lbf).

Friction-free piston motion delivers smooth, consistent operation while minimizing downtime.

A four-column frame ensures structural rigidity and accommodates larger sample sizes.

Interface options include a tethered handheld controller, a Bluetooth-enabled wireless panel, and a virtual controller - all of which connect seamlessly to Horizon data analysis software.

- All interface option works with Horizon data analysis software

Image Credit: Tinius Olsen

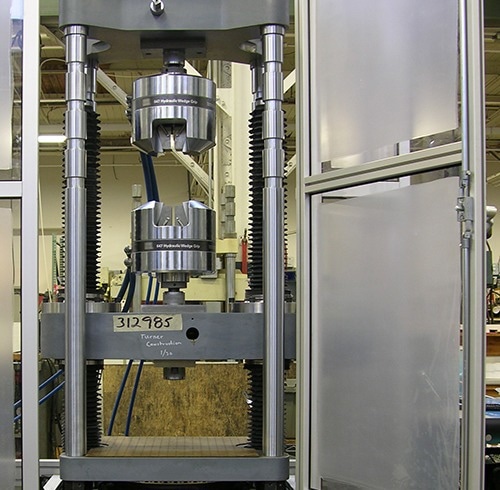

Options and Accessories

- External grips and fixtures can be mounted securely and easily.

- In-head pocket grips are available to accommodate both flat and round tensile specimens.

- Crossheads can be configured as closed, semi-open, or fully open to simplify specimen loading and unloading.

- Columns can be extended by up to 914 mm (36 in) to expand the available test area.

- An adjustable top crosshead can be added, with optional column notching to reposition it for improved working height and ergonomics.

- A full selection of extensometers and deflectometers is offered, using technologies such as video, laser, encoder, LVDT, and strain gauge.

- Furnaces and environmental chambers may be installed for conducting tests at elevated or reduced temperatures.

- Safety enclosures equipped with interlocks can be implemented to safeguard operators from hazardous specimen failures.

Image Credit: Tinius Olsen