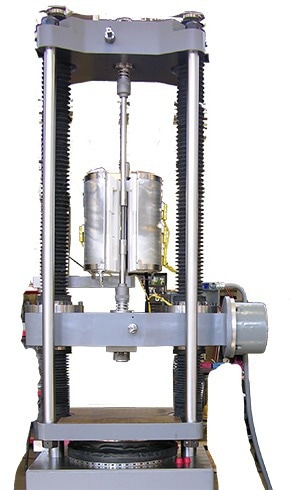

The model 1500SL is designed to evaluate materials and components for shear, flexural, compression, and tension strength. Its robust construction, built with high-quality materials and components, upholds Tinius Olsen’s reputation for outstanding system performance, ease of use, and long-term durability.

Tinius Olsen hydraulic testers have long been regarded as the benchmark for accuracy, reliability, and versatility in universal testing equipment. With thousands of units in operation globally, the SL series continues to set the standard for hydraulically powered universal testing machines.

Features and Benefits

- The system supports tension, compression, transverse, shear, and other testing applications up to a maximum force of 1500 kN (300,000 lbf).

- Its four-column, heavy-duty design accommodates the testing of larger samples.

- Friction-free piston operation ensures smooth, controlled testing and minimizes downtime.

- Multiple system interface options are available, including a tethered handheld device, a wireless Bluetooth interface, and a virtual machine controller.

- All interface types are compatible with Tinius Olsen’s Horizon data analysis software.

Image Credit: Tinius Olsen

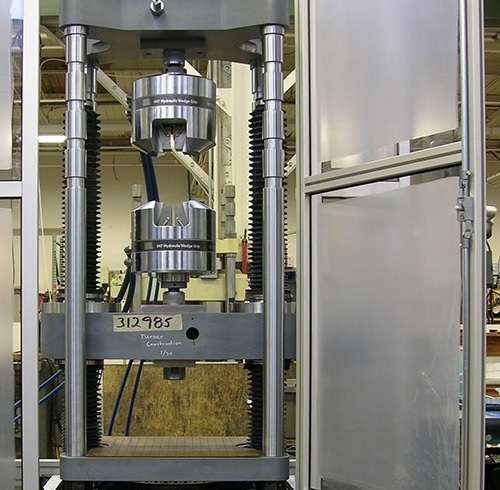

Options and Accessories

- Crossheads are available in closed, semi-open, or fully open configurations to simplify specimen loading and unloading.

- Columns can be extended by up to 914 mm (36 inches) to increase the size of the test area.

- The top crosshead can be made adjustable, and columns can be notched to allow repositioning for a more ergonomic working height.

- In-head pocket grips are available to accommodate both flat and round tensile specimens.

- A full selection of precision extensometers and deflectometers is offered, including options based on video, laser, encoder, strain gauge, and LVDT technologies.

- Furnaces and environmental chambers can be integrated for testing under high or low temperature conditions.

- Safety enclosures with interlocks can be installed to protect operators from high-energy specimen failures.

Image Credit: Tinius Olsen