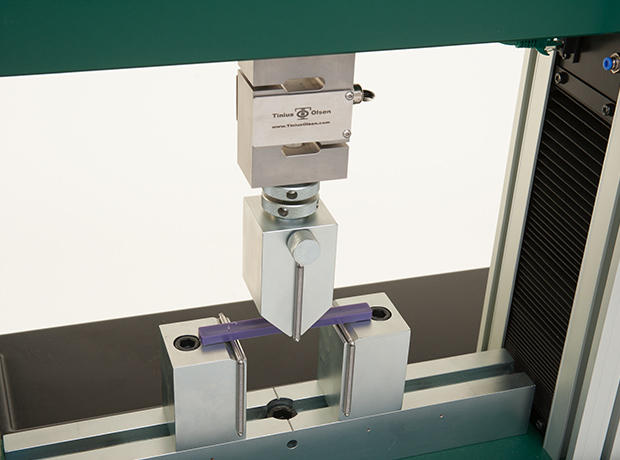

The model 25ST is designed for testing the tension, compression, flexure, and shear strength of materials and components. Its robust construction incorporates high-quality materials and components, upholding our reputation for superior performance, ease of use, and long-term durability.

A wide selection of loadcells with varying capacities ensures accurate load measurements, from the smallest specimens to those reaching the machine’s full capacity. With the addition of specimen grips, strain measurement instrumentation, and Tinius Olsen’s Horizon software, the system becomes a complete and powerful testing solution.

Features and Benefits

- Capable of performing tension, compression, flexure, shear, and other tests up to 25 kN / 5000 lbf

- Multiple system interface options, including a tethered handheld device, wireless Bluetooth panel, or virtual machine controller

- All interface types are compatible with Horizon data analysis software

- Meets or exceeds national and international materials testing standards

- Machine column includes eight full-length T-slots for securely mounting accessories

- Integrated pneumatic ports provide local air supply to pneumatic grips

Image Credit: Tinius Olsen

Options and Accessories

- Test frame can be extended by up to 400 mm (16 in) to accommodate larger test areas

- Grips and fixtures are easily mounted and changed using a simple locking pin

- Available precision extensometers and deflectometers include video, laser, encoder, strain gauge, and LVDT options

- High and low temperature testing supported via optional furnaces and environmental chambers

- Safety enclosures with interlocks can be installed to protect operators from specimen failures

- Tinius Olsen’s Horizon software connects seamlessly to the testing system for operator control

Image Credit: Tinius Olsen