The VFG Digital Force Gauge from Mecmesin is the most advanced touch screen force gauge, powered by Vector OS.

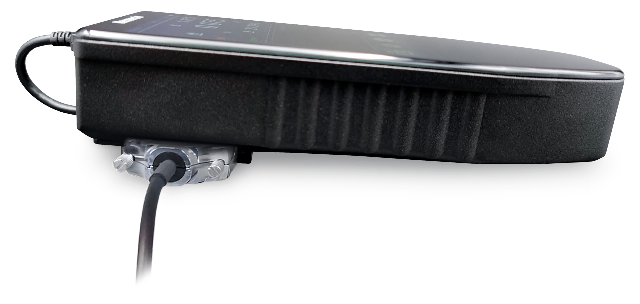

It is a handheld device suitable for rough environments to deliver accurate and reliable measurements. The device can be used for tensile and compressive testing in the field or as part of a testing system for use in production, quality control and research and development laboratories.

Overview

The VFG is Mecmesin’s most powerful digital force gauge, packed with unique features and an easy-to-use touch screen interface. This enables easy navigation.

Vector OS software is the main highlight of VFG. Users can configure the gauge according to their needs, analyze test results quickly in the field and customize the touch screen interface.

Featuring capacities ranging from 2.5 to 2500 N (0.5 to 550 lbf), the VFG can be used for a wide range of industrial applications. All models are highly accurate to ±0.1% of full scale with readings displayed in all common measurement units — kN, mN, N, kgf, lbf, gf and ozf.

In addition to being used for push and pull tests with its internal load cell, the VFG also serves as a universal display for external “smart” force and torque transducers. In this way, the users can expand the capabilities of a VFG by connecting additional sensors to a Smart Adapter, that allows tension, compression and torsion to be measured, all using one gauge.

The VFG offers a variety of test features and data analysis capabilities:

- Maximum and First Peak modes — users can register the key values from the test

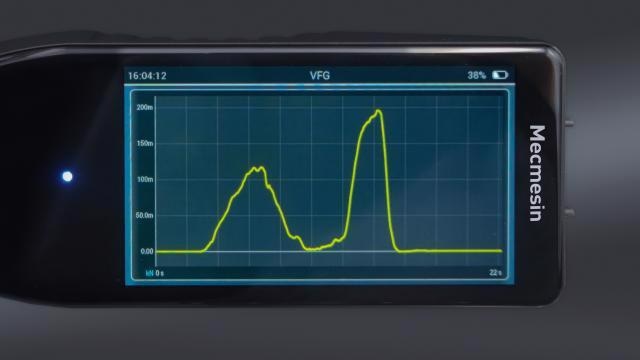

- Graphing mode — produces a live curve on the display to help identify vital events during the test

- Fast internal sampling at 5 MHz enables a data-acquisition rate of 2,000 times per second, thus ensuring sudden break-force readings are captured accurately

- Visual pass/fail alarms — operators are alerted immediately when testing

- Overload warning — reduces the risk of accidental damage to the load cell

- Statistical summary — displayed readings can be stored in built-in memory for statistical analysis within the gauge

- Expandable external memory — all the raw data points can be saved on a 32 GB micro-SDHC card so users can test quickly and download results later

- Data can be directly output to a PC or printer for further analysis

- Users can mount the gauge to test stands and connect to external load cells and torque sensors — outstanding versatility makes it ideal for various applications

The 5″ color touch screen features an intuitive interface that simplifies operation and provides quick access to configuration menus and advanced tests. Users can also configure the display to show only the options they want to see. Pinch and zoom option makes the live graph expandable.

Rugged aluminum housing that is shaped to fit the hand makes the VFG a hand-held device that can be used anywhere. Due to its ease of attachment to a motorized stand, this tension and compression tester is an affordable option for testing requirements that require optimum repeatability. Alternatively, users can also integrate this powerful force gauge into their own custom test rigs.

The device is supplied in a robust carry case with standard accessories, including a USB-C charging cable and a USB-C to USB-A adapter, and is powered by a lithium-ion battery. To protect the gauge from accidental damage, a removable rubber bumper is included.

A calibration certificate traceable to national standards is included at no additional charge — ensuring full compliance with external audits.

Tension and compression tests can be performed just about anywhere, making it the solution of choice for factory or outdoor testing.

Intuitive Touch Screen

- Advanced touch screen force and torque gauges, powered by Vector OS

- Handheld instruments built for rough environments to deliver accurate measurements

Image Credit: Mecmesin Ltd

Vector OS

The touch screen instruments are powered by Vector OS, Mecmesin’s technology platform for its latest force and torque test equipment. It provides user interfaces that are convenient and customizable, as well as offers advanced data capture and analysis.

Users can connect all Vector instruments to a computer and use Mecmesin’s VectorPro Lite software for data analysis and reporting to increase overall testing power.

Image Credit: Mecmesin Ltd

Force and Torque Sensors

The VFTI, AFTI, AFG and VFG are versatile force and torque indicators designed for use with Mecmesin’s “Smart” tension and compression load cells, as well as “Smart” static and rotary torque sensors.

Readings are shown as live values with a peak-hold function in both tension and compression, or as torque in both clockwise and counterclockwise directions.

Data can be streamed in the form of continuous or single readings for storage on PCs, printers and data loggers.

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Image Credit: Mecmesin Ltd

Accessories

The sample must be gripped and held correctly to ensure accurate results. With the wide array of accessories, users are sure to find the right accessory for their needs. Specifications (such as the load rating) are displayed on every grip and fixture.

Wedge Grip (large), 5 kn, 5-16 UNC. Image Credit: Mecmesin Ltd

VFG and AFG Comparability

- The VFG model offers a touch screen with a full-color display that supports touch and gestures, with live graphing and customizable interface, while this feature is absent in the AFG model.

- Vector OS provides configuration deployment, future software updates, new features and custom applications in the VFG while the AFG lacks these.

- The smart sensors present in both the models back various external “Smart Sensors” used for a variety of applications.

- The capacity of both VFG and AFG is 2.5 N–2.5 kN and they can capture readings from as low as 0.0005 N to 2,500 N.

- Both models have an accuracy of ±0.1% of full scale. For instance, VFG 500 has a full-scale capacity of 500 N and is highly accurate to ±0.5 N at any point between 0–500 N.

VFG has better storage capacity with an expandable memory (Micro SD card supports up to 32 GB) while it is not the same for AFG.

Key Specifications

Tension and Compression

Source: Mecmesin Ltd

| VFG Touchscreen |

| Measurement range |

All force gauges measure from zero to the value indicated in the table below. |

| Model |

VFG 2.5 |

VFG 5 |

VFG 10 |

VFG 25 |

VFG 50 |

VFG 100 |

VFG 250 |

VFG 500 |

VFG 1000 |

VFG 2500 |

| N |

2.5 |

5 |

10 |

25 |

50 |

100 |

250 |

500 |

1000 |

2500 |

| lbf |

0.55 |

1.1 |

2.2 |

5.5 |

11 |

22 |

55 |

110 |

220 |

550 |

| kgf |

0.25 |

0.5 |

1 |

2.5 |

5 |

10 |

25 |

50 |

100 |

250 |

|

| Resolution |

1:50,000

eg. VFG 500 when measuring in newtons has a resolution of 0.01 N |

| Accuracy |

±0.1% of full scale

eg. VFG 500 has a full-scale capacity of 500 so is accurate to ± 0.5 N at any point between 0 - 500 N |

| Units of measurement |

mN, N, kN, gf, kgf, ozf, lbf |

| Sampling Rate |

5,000,000 Hz |

| Overload Rating |

150% of full scale |

| Storage |

| On-board/built-in memory |

8 MB (approx. 500 stored readings) |

| Expandable memory |

Up to 32 GB (via SDHC card) |

| Dimensions |

| Width |

72 mm |

| Height |

205 mm |

| Depth |

42 mm |

| Weight |

740 g |