Melt flow index testing is a simple, reliable, and repeatable way to assess and evaluate the quality of polymer resin. By measuring the polymer's melt flow rate and comparing it to prior batches, users can check polymer quality and save time and money by eliminating inferior plastic batches using a data-centric approach. Dynisco provides easy and effective quality control systems for polymer processing.

LMI6000 Melt Flow Indexer Auto-Lift

Image Credit: Dynisco

- Test Methods: Method A [Standard], Method A/B, B, C, D [Digital Encoder Option]

- Barrel Operating Temperature: 400 °C [Standard], 500 °C [Option] ±0.1 °C

Tests can now be partially automated using a new electromechanical lift system, allowing one operator to execute tests on several machines at once. The lift mechanism enhances test accuracy and safety. The LMI6000 is more convenient than ever thanks to its improved hardware design, partial automation, and a bigger, movable touchscreen interface.

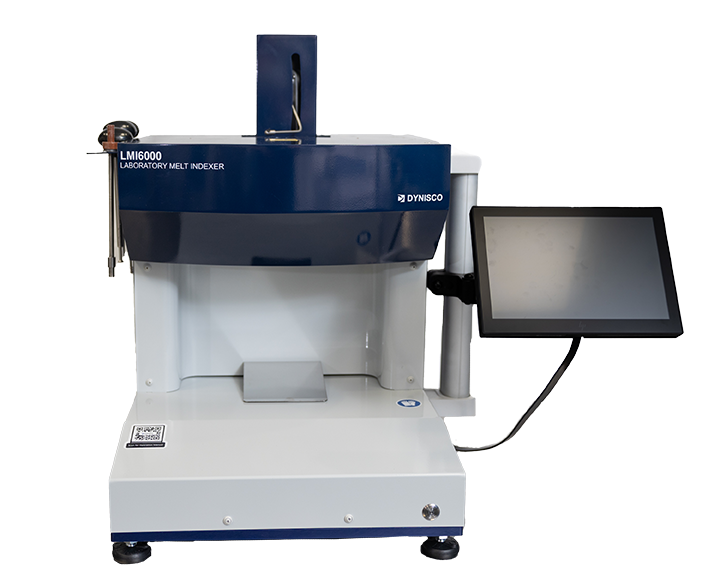

LMI6000 Melt Flow Indexer Base Unit

Image Credit: Dynisco

- Test Methods: Method A [Standard], Method A/B, B, C [Digital Encoder Option]

- Barrel Operating Temperature: 400 °C [Standard], 500 °C [Option] ±0.1 °C

The LMI6000 Base provides all the features we know form the LMI5500 but with many of the benefitial features LMI6000 Auto-Lift provides. With a range of testable characteristics, such as MFR, IV, and melt density, for material analysis and quality control. The user-friendly software on the LMI6000 Base shows material analytics, records test data, and guides the operator through the test processes. With it's comfortable working height, integration of the tool holder and adjustable side mounted touchscreen display the LMI6000 Base brings an updated and more convientent look to the LMI5500.