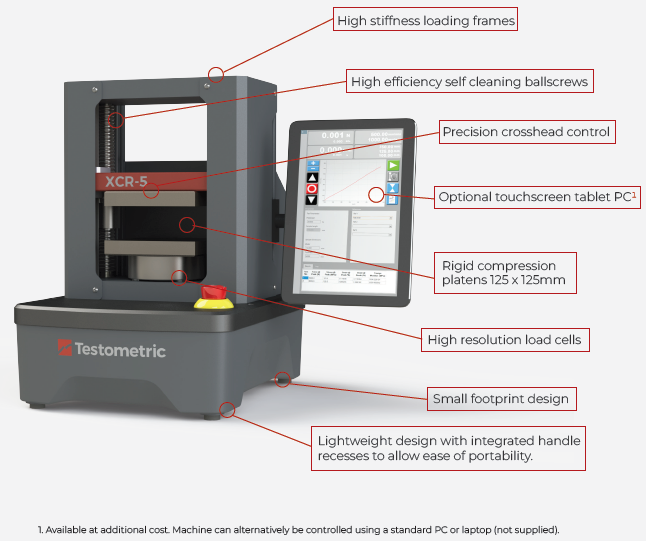

The XCR-5 Crush Tester is built for compression testing of corrugated board, liner, and fluting, and supports standard methods, including FCT, ECT, PAT, RCT, CMT, and CCT.

Source: Testometric Company Ltd

|

XCR-5 |

| Force Capacity kN |

5 |

| Accuracy |

Better than +/- 0.5 % of reading down to 1/1000th of load cell capacity |

| Compression Platen Size mm |

125 x 125 |

| Optional Fixtures (to be selected) |

ECT Edge Crush Holding Blocks, PAT Pin Adhesion Fixture, RCT Ring Crush Fixture, CMT Corrugating Medium Test Fixture, CCT Corrugated Crush Test Fixture |

| Max Platen Opening mm |

125 |

| Position Control Resolution mm |

0.0001 |

| Minimum Speed mm/min |

0.001 |

| Maximum Speed mm/min |

300 |

| Speed Accuracy |

+/- 0.1 % under stable conditions |

| Data Acquisition Rate (at PC) |

500 Hz |

| PC Connection |

USB |

| Machine Configuration |

Dual-column, bench-mounted with precision-guided crosshead |

| Frame Stiffness kN/mm |

60 |

| Weight kg |

40 |

| Operating Temperature °C |

-10 to +40 |

| Operating Humidity |

+10 to +90 % non-condensing |

| Electrical Supply |

100-240 V, 1 ph 50/60 Hz |

| Power kW |

0.45 |

Made to Measure

This fully digital testing system provides high precision control and accuracy, with automated computer control of all test methods to keep it simple to operate. Its high-resolution load cells provide exceptional accuracy, performing better than +/- 0.5 % and reliability down to 1/1000th of their capacity.

The system automatically recognizes load cells and extensometers, storing calibration parameters on-device. Built-in software calibration check for instant verification of machine accuracy, while the robust load cell design withstands up to 800 % overload capacity without damage.

High-efficiency pre-loaded, self-cleaning ballscrews are fitted with sealed-for-life lubricated end bearings for fast, quiet testing. A precision crosshead guidance system ensures alignment and smooth operation, while a digital AC servo drive and a brushless servo motor deliver maintenance-free operation and 20,000 pulses/rev positional accuracy.

The device supports high-speed data acquisition across four synchronous channels, with an expandable channel interface for additional devices such as extensometers, micrometers, calipers, and balances. High-stiffness loading frames with solid, specialized steel crossheads and rigid extruded support columns feature T-slots for accessory mounting.

Comprehensive safety features include overload, overtravel, and impact protection, and telescopic covers provide extra protection for ballscrews against dust and testing debris. The device has a compact footprint design for efficient use of bench space.

Image Credit: Testometric Company Ltd

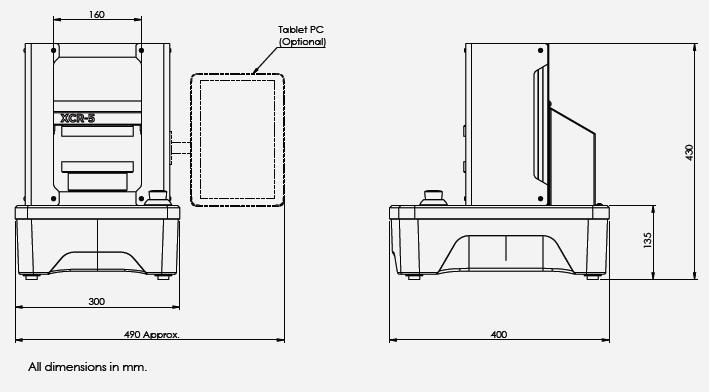

XCR-5 Dimensions

Image Credit: Testometric Company Ltd

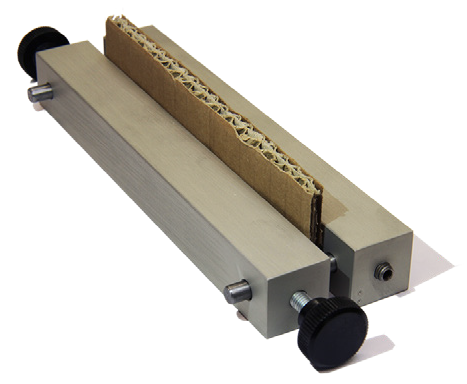

ECT Edge Crush Holding Blocks. Image Credit: Testometric Company Ltd

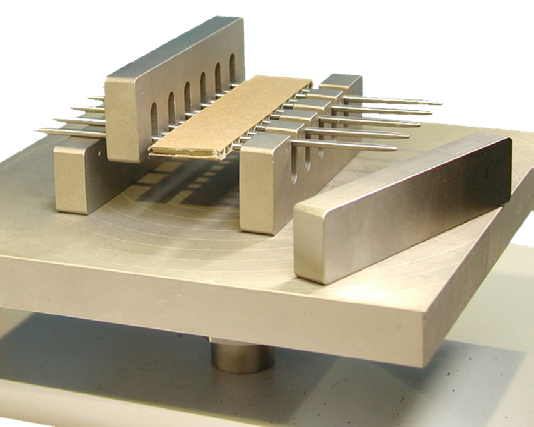

PAT Pin Adhesion Fixture. Image Credit: Testometric Company Ltd

CMT Corrugating Medium Test Fixture. Image Credit: Testometric Company Ltd

Built for Precision

Force Measurement

The system is universally calibrated, exceeding Grade 0.5 standards (EN 7500-1, DIN 51221, ASTM E-4, AFNOR A03-501), and offers a wide measurement range from 0.4 % to 100 %. It features automatic load cell identification, high-resolution 1 part in 500,000, and electronic load cell protection.

Extension Measurement

This device has a maximum resolution of 0.0001 mm with an accuracy of +/- 0.01 mm across the full frame length. It provides versatile measurement options, including absolute, relative, and auxiliary modes, with selectable units in mm, inches, and percent.

Speed Control

The drive system provides exceptional low-speed performance with speeds down to 0.001 mm/min, and it is equipped with built-in temperature and current protection.

Load Frame

The machine is built on a rigid frame that uses a precision linear guidance system and a robust extruded support column. With a frame stiffness of 60 kN/mm and a built-in K factor facility, the system is exceptionally strong and stable.

Bellows protect the recirculating ball screw, and a suite of advanced safety features, including electronic limit trips, total travel trips, and customer-programmable safety stops, ensure reliable operation.

Electronics System

The system features a modular electronics design that provides fast data transfer to the PC at 500 Hz via a high-speed USB connection. Extensive input options allow for the simple plug-in of a wide range of extensometers and other accessories via dedicated interface modules.

Safety Features

The system is equipped with extensive safety features to ensure the highest levels of operator safety, including an E-Stop, programmable extension limits, and overload/impact detection. It is also fully compliant with global safety directives, such as the Machinery Directive (2006/42/EU), the Low Voltage Directive (2014/35/EU), and the Electromagnetic Compatibility Directive (2014/30/EU).

Optional Tablet PC

When paired with the optional TPC1 tablet PC, the machine becomes a robust, standalone system, eliminating the need for an external PC or laptop.

Using a specialized version of the WinTest software optimized for touchscreen control, the tablet provides a fully-featured testing environment where the user can create and store unlimited methods and results. The included mounting arm attaches to the machine column T-slots. It is fully adjustable in height, reach, and viewing angle, allowing the user to find the most ergonomic working position.

Alternatively, the machine can be connected to a conventional desktop PC or laptop using the powerful WinTest EC software.

Image Credit: Testometric Company Ltd

Tried and Tested Software

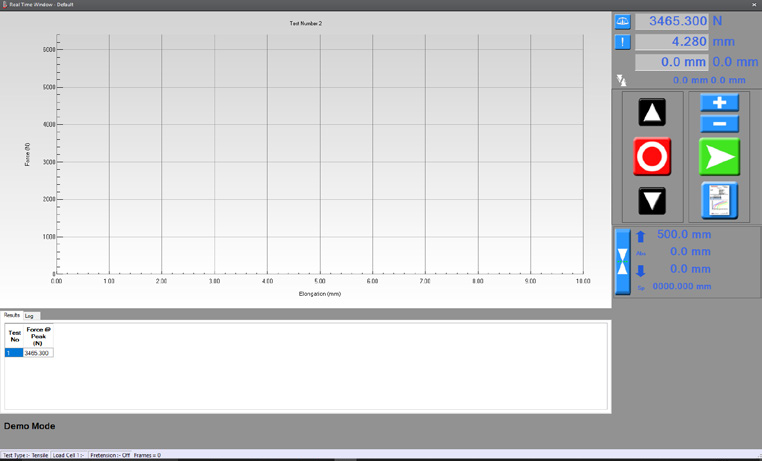

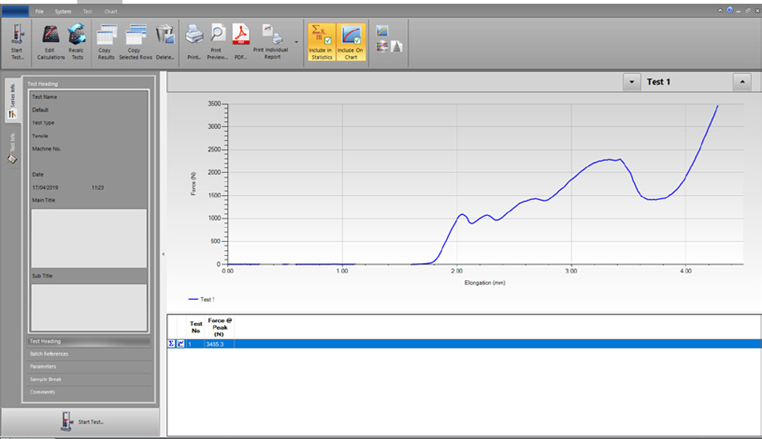

All Testometric models are supplied with the comprehensive WinTest Analysis software package.

WinTest Analysis, developed over many years, offers a flexible and user-friendly software solution for all kinds of material testing. It includes pre-defined test methods for tensile, compression, flexural, peel, shear, tear, cyclic, creep, and multi-stage tests.

The software comes preloaded with a broad selection of industry-standard methods and allows users to create and store an unlimited number of custom tests. All test data is automatically saved and easily exported to programs such as Word, Excel, or SPC systems for streamlined reporting and analysis.

With the optional RCE remote connection, all machines can be web-linked directly to Testometric. This enables convenient remote investigation, monitoring, and software upgrades, ensuring the system is always up-to-date and operating optimally.

Real time test screen. Image Credit: Testometric Company Ltd

Test analysis screen. Image Credit: Testometric Company Ltd

Standing the Test of Time

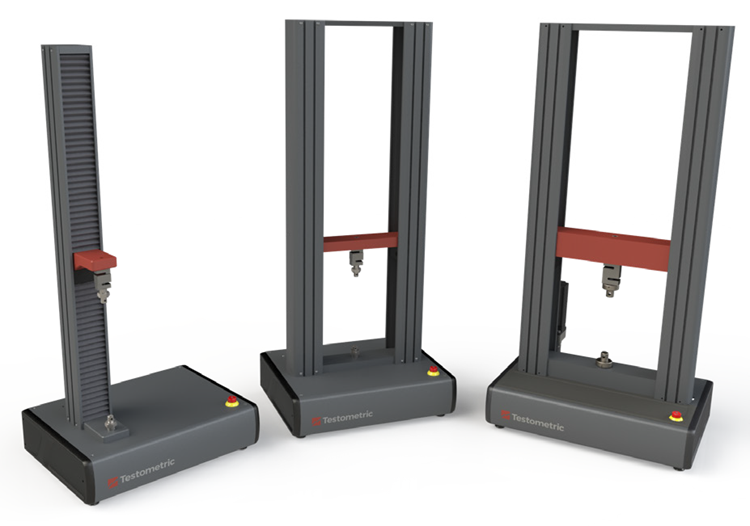

Testometric, a private limited company, has been designing and manufacturing testing machines and quality control equipment since its establishment in 1970.

Over fifty years of ongoing development have led to a core product line of universal strength testing machines for tension, compression, flexure, shear, and product testing. Testometric machines are utilized in more than 100 countries and supported by a network of offices and authorized agencies.

The company serves all industries and educational sectors and is renowned for its innovation, product quality, and outstanding customer support.

Image Credit: Testometric Company Ltd