Electromechanical Creep Testing Machines

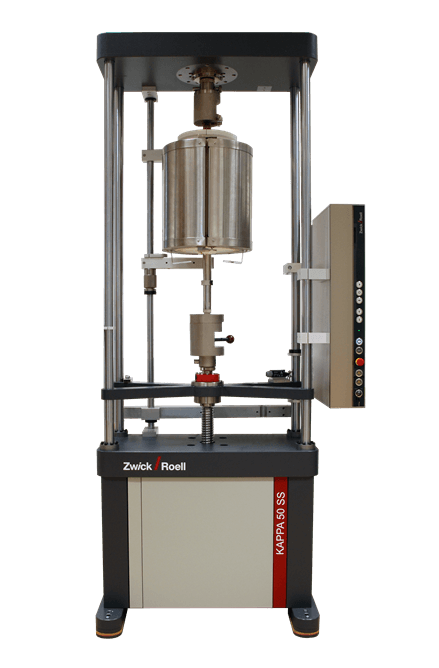

Kappa SS

The Kappa SS creep-testing machine is fitted with a core lead screw and is ideal for creep tests and advanced creep tests requiring maximum precision in force control.

- Load frame with single lead screw drive and precision guidance provided via four steel columns, offering precise axial loading and highest durability

- Load string with ideal alignment properties in compliance with ASTM E292

- Constant moving crosshead speed via precision central ball screw

- High-resolution force and travel measurement for ideal control properties, particularly at very low test speeds

- Creep tests and stress relaxation tests; user-programmed load-cycles

- Large range of machine accessories for flexible application options, complemented by smart electronics and software

- Optional digital closed-loop force and strain control

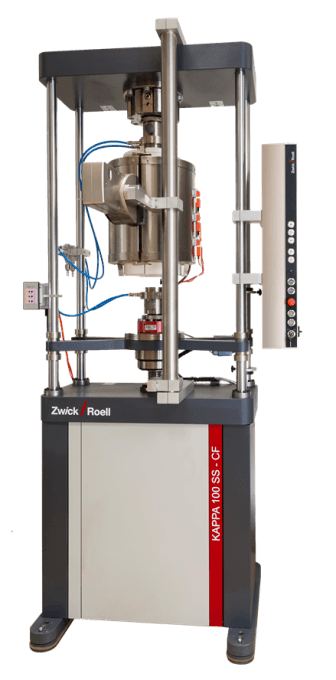

Kappa SS - CF

The Kappa SS - CF creep testing machine is fitted with a central lead screw and is ideal for creep tests and strain-controlled creep fatigue (CF) tests needing highest precision in strain control. Along with the non-contact videoXtens HT/TZ extensometer, highest flexibility and exceptional control features are integrated into an innovative testing machine.

- Applications: creep fatigue tests, creep tests, creep fatigue interaction and relaxation tests; user-programmed load cycles

- High precision gears and servo motor positioned centrically in the load line, moving up and down with the moving crosshead

- In contrast to regular electromechanical creep testing machines, the Kappa SS - CF creep testing machine is unique because of its superior linearity force-deflection curve with backlash-free zero crossing

- Virtually play-free drive is patent pending: special load train bearing guarantees ideal alignment properties in compliance with ISO 23788 and NADCAP requirements

- Load frame with single lead screw drive and precision guidance provided via four steel columns, giving precise axial loading and maximum durability

- High-resolution force and travel measurement for ideal control properties, particularly at very low test speeds

- Constant moving crosshead speed via precision central ball screw

- The huge range of machine accessories offers flexible application options, which are complemented by testXpert II software and testControl intelligent electronics

- Optional digital closed loop control for force and strain

Kappa DS

The Kappa DS creep testing machine is fitted with a double lead screw and is engineered for creep tests and advanced creep tests. High flexibility is integrated with highest precision in a single testing machine.

- Load frame with double lead screw drive and precision guidance provided via four steel columns, offering precise axial loading and highest durability

- Large crosshead travel allows machine to house a broad range of tests and specimens

- Load string with ideal alignment properties in compliance with ASTM E292

- Constant moving crosshead speed of +/-0.1% of specified speed in a measurement range from 1 µm/hour to 100 mm/minute

- High-resolution force and travel measurement for ideal control properties, particularly at very low test speeds

- Wide range of machine accessories for flexible application options, complemented by smart electronics and software

- Selectable digital closed loop force and strain control Creep tests and stress relaxation tests; user-programmed load cycles

KAPPA Multistation for Plastics

The Kappa Multistation electromechanical creep testing machine is a compact, flexible, and precise creep testing machine fitted with separately controlled test axes. It was built particularly for the analysis of the creep behavior of polymer and plastics materials at advanced R&D laboratories. This creep testing machine offers latest solutions for applications such as creep tensile and creep flexure tests to ASTM D2990 and to ISO 899-1 (tensile) and -2 (flexure). The versatility of the system can be improved with additional applications like quasi-static tensile, flexure, and relaxation tests. The Kappa Multistation for plastics integrated with a Multistation optical strain measurement system and a temperature chamber is presently available for creep testing applications with force capacities ranging from 5 N up to 10 kN per axis.

- A very cost efficient and compact design

- Different simulated environmental conditions

- High-precision load cells mounted on moving crosshead

- Versatile creep testing system with five or six independent controlled test axes in single test frame

- Rigid load frame construction

- Ability to incorporate one or two temperature chambers; containing all test axes for a full and profound analysis of the specimen material properties at varying temperatures such as tests according to the stepped isothermal method (SIM)

- Combination with non-contact videoXtens strain measurement system

- videoXtens extensometer does not impact the specimens (which is required by the standards)

- Test monitoring and analysis with special testXpert II Multistation software

Accessories

For maximum reliability and precision, the Kappa series of creep testing machines is the ideal choice. The following accessories are also available:

- High-temperature furnaces for ceramics (up to 1,600 °C)

- High-temperature furnaces for metals (temperature range +100/200 °C to 1,200 °C)

- Temperature chambers (temperature range -80 °C to + 280 °C/optional +350 °C)

- Mechanical high-temperature extensometer with horizontal or axial sensors

- Temperature controller

- High-temperature load string for electromechanical and lever arm creep testing machines testXpert II electronics and software. This easy-to-use system is equipped with modern technology and based on a versatile modular concept, ensuring maximum data security. The large number of test program types allows the requirements of a broad range of standards, applications, and test types to be realized.

- Optical high-temperature extensometer with laser speckle technology

- High-temperature adapter:

- Standard adapter for flat specimens and pipe section specimens

- Standard adapter for threaded specimens in metric and Imperial/US dimensions

- Standard adapter for CT specimens to ASTM E1457 for crack propagation creep tests