The GCP100 is the first gas chromatograph to feature certified built-in cybersecurity, setting a new benchmark for real-time analysis of complex gas mixtures. Designed to support operators across natural gas, biogas, oil, and petrochemical industries, it delivers both precise analytics and enhanced data protection.

Engineered for ease of use and flexible deployment, the GCP100 is ideal for remote or hazardous environments. Its modular, weatherproof design ensures reliable performance while keeping the total cost of ownership to a minimum.

Key Benefits

- The world’s first gas chromatograph with built-in cybersecurity

- Integrated WiFi connectivity with a 4-inch gesture-controlled display for seamless remote access

- Industry-leading accuracy with 1 ppm detection and extended operating temperatures from 60° to 100 °C

- Reduce downtime by up to 75 % with digital connectivity, dynamic QR codes, and My Measurement Assistant+

- Designed for sustainability with ultra-low power consumption of just 12 watts and a flexible, modular analytical design

Image Credit: ABB Measurement & Analytics

Benefits

Developed with customer needs in mind, the GCP100 enhances efficiency, reliability, and accuracy in hydrocarbon processing - boosting productivity, improving quality control, and reducing overall costs.

- Modern analyzer designed for peace of mind

- The GCP100 combines industry-leading cybersecurity with proven reliability, high accuracy, and low-maintenance operation.

- An intuitive, gesture-controlled user interface offers quick access to detailed system information.

- Built-in advanced diagnostics provide expert insights, self-checks, and continuous health monitoring - directly from the analyzer.

- Accurate and precise analyses

- The GCP100 delivers accurate, high-precision analysis of process streams, helping identify costly disruptions and enabling timely responses to process changes.

- Rugged, weatherproof, compact design

- Engineered for durability, the GCP100’s gas chromatographic modules operate reliably in all environmental conditions (even the most extreme), ensuring continuous, long-term performance.

Image Credit: ABB Measurement & Analytics

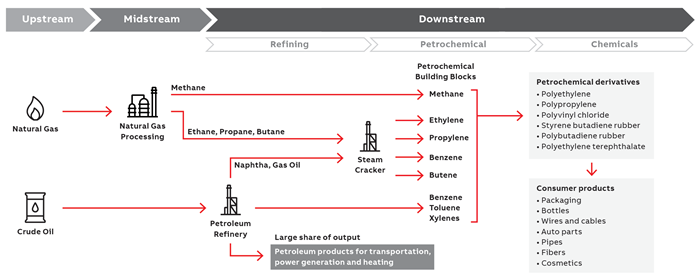

Applications

The GCP100’s analytical capabilities extend from custody transfer in the upstream market to process control in midstream and downstream operations - making it far more than a standard natural gas analyzer.

Versatile and agile, it integrates seamlessly across all sectors of the hydrocarbon processing industry, including:

- Oil refineries

- Petrochemical plants

- Natural gas production and transmission

- Natural gas fractionation

Image Credit: ABB Measurement & Analytics

Image Credit: ABB Measurement & Analytics

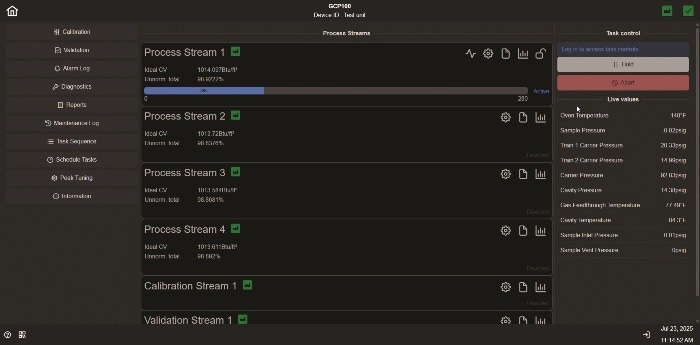

User Interface

Intuitive User Interface on a Modern Software Platform

The GCP100 offers a user-friendly yet comprehensive interface, supported by advanced diagnostic software that monitors key performance indicators and enhances the overall user experience.

Browser-Based Interface

Whether in the field or at the office, the browser-based interface provides fast, remote access to operations, diagnostics, and data handling. Key features include:

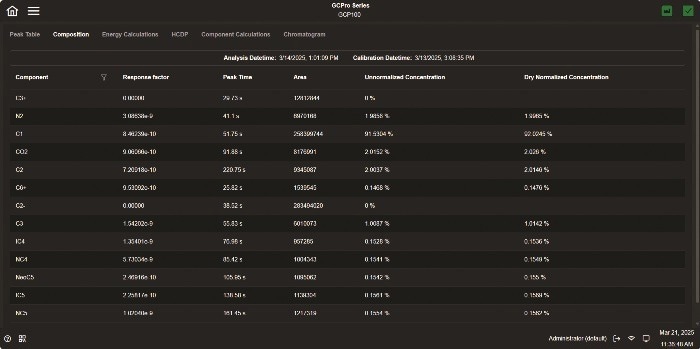

- Real-time and historical analysis data

- Settings and configuration parameters

- Alarm display, acknowledgement, and detailed insights

- Process event tracking

- Reporting and export of historical data

- System information

- Role-based, user-defined access control

Human Machine Interface (HMI)

The GCP100 is equipped with a 4-inch display, informational LEDs, and a gesture-controlled interface, making it easy to operate in any condition.

HMI Panels Display

- System information

- Dynamic QR code

- Analyzer status

- Measurements

- Alarms

Image Credit: ABB Measurement & Analytics

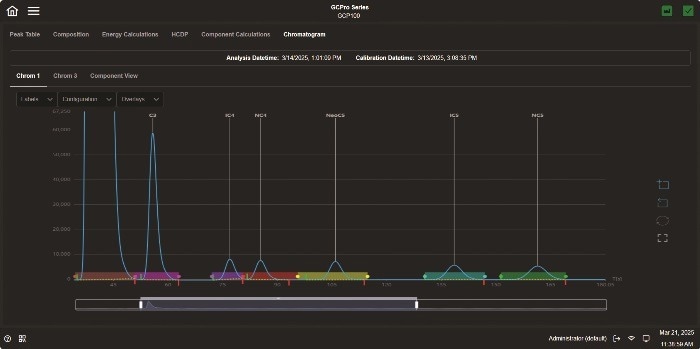

Software

Inside the GCP100, advanced software delivers expert guidance and real-time analytical insights directly from the analyzer, including:

- Health metrics monitoring

- Predictive maintenance

- Automatic startup and retention time tuning algorithms

- Analyzer diagnostics

Home screen. Image Credit: ABB Measurement & Analytics

Chromatogram. Image Credit: ABB Measurement & Analytics

Report/Results. Image Credit: ABB Measurement & Analytics

Maintenance

Easy Installation, Operation, and Maintenance

The GCP100 is built for peace of mind, delivering consistent performance while helping reduce the risk of unplanned maintenance.

Low Maintenance, Simple Operation

Designed with the user in mind, the GCP100 simplifies service and upkeep. Routine maintenance can be carried out from the front panel, and its modular design ensures all replaceable parts are easy to access in the field - minimizing downtime and reducing the need for specialized training.

Easy Installation and Commissioning for Hazardous Areas

With its flameproof, explosion-proof construction, the GCP100 eliminates the need for complex purging systems. It features front access and a simple wall-mount design, enabling fast and reliable commissioning across a wide range of environments.

Dynamic QR Code and autoID Assistance

ABB’s dynamic QR code allows for instant product health checks and troubleshooting without a direct system connection. Combined with the AutoID feature, it provides both static analyzer identification and real-time updates on configuration and system health, enabling faster, more efficient support from ABB experts.

GCP100 the First Gas Chromatograph with Built-in Cybersecurity

Video Credit: ABB Measurement & Analytics

My Measurement Assistant+

My Measurement Assistant+ is a digital support platform powered by generative AI, cloud services, and augmented reality. It offers centralized access to diagnostics, device information, and remote support, streamlining maintenance and troubleshooting across industrial operations.

Image Credit: ABB Measurement & Analytics