Litesizer DIF is a cutting-edge particle size analyzer that spans 10 nm to 3.5 mm, using over six decades of laser diffraction technological advancement.

This laser diffraction particle size analyzer incorporates a premium-grade optical configuration, delivering exceptional measurement accuracy. An optional image analysis module is accessible for supplementary morphological assessment and dependable identification of oversized particles.

The Kalliope software streamlines particle sizing operations, eliminating the necessity for comprehensive operator preparation – measurements commence within three steps. The Quick-Click mechanism facilitates straightforward transitions among dispersion units, reducing operational mistakes. Protective mechanisms for both liquid and dry dispersion guarantee straightforward, protected functionality.

The reinforced steel framework and the decoupled optical platform guarantee consistent performance, spanning industrial settings to precision-controlled facilities.

Grounded in established technological foundations, this represents state-of-the-art laser diffraction innovation. Litesizer DIF: From First to Best.

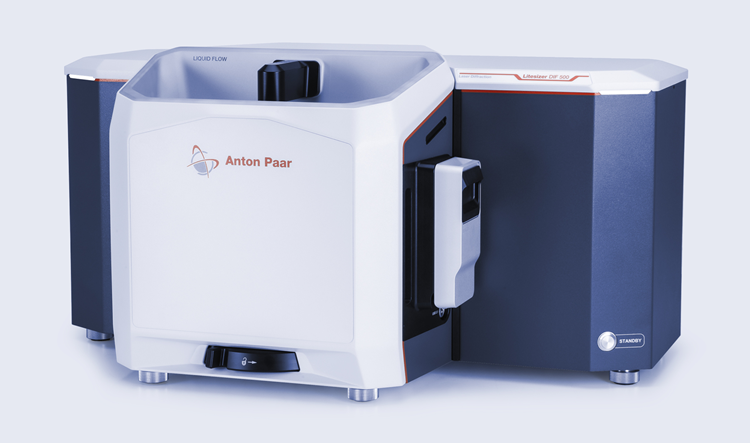

Litesizer DIF 500

Image Credit: Anton Paar GmbH

- Image analysis module available for additional shape analysis

- Measure samples from 0.01 µm to 3,500 µm

- Kalliope software: No training required, dedicated QC mode

Litesizer DIF 300

Image Credit: Anton Paar GmbH

- Kalliope software: No training required, dedicated QC mode

- Image analysis module available for additional shape analysis

- Measure samples from 0.1 µm to 2,500 µm

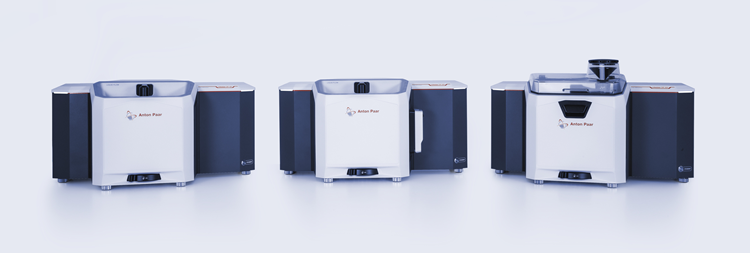

Litesizer DIF 100

Image Credit: Anton Paar GmbH

- Kalliope software: No training required, dedicated QC mode

- Measure samples from 0.1 µm to 1,000 µm

- Switch between liquid and dry dispersion in just one move

Key Features

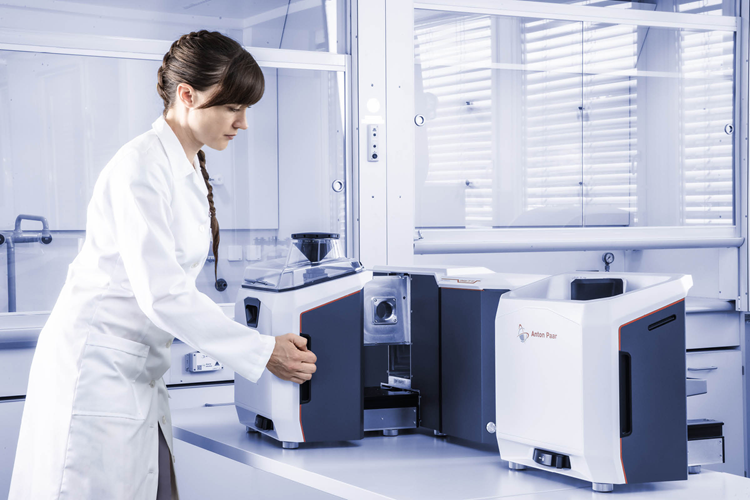

On Quality, Anton Paar Leads the Way

Image Credit: Anton Paar GmbH

Litesizer DIF represents an optimal solution for particle characterization through its superior construction quality. It incorporates premium-grade internal and external components, enabling the apparatus to generate exceptional measurement data.

Litesizer DIF 500 facilitates analysis across an extensive particle dimension spectrum, accommodating dimensions between 0.01 µm and 3,500 µm. Litesizer DIF 300 and 100 address specialized applications that require the examination of restricted dimensional ranges. In addition, the Litesizer DIF can switch between liquid and dry dispersion in a single motion. All analyzers have a 10-year warranty on lasers.

Kalliope: The Benchmark Software for Particle Sizing

Image Credit: Anton Paar GmbH

Through Kalliope, operators can quickly understand operational procedures via the streamlined single-interface methodology (parameter configuration, data collection, and interpretation). The device's QC functionality delivers reproducible, precise measurements through customizable access protocols and parameter restriction. The apparatus operating in QC mode furnishes a straightforward indication regarding conformance to predetermined specifications.

Consequently, measurements materialize within three selections with diminished operator preparation requirements. Furthermore, a pharmaceutical variant incorporating data safeguarding protocols, access management, and transaction documentation is integrated, establishing Kalliope's alignment with the US FDA's 21 CFR Part 11 requirements.

Efficient Dispersion, Maximum Safety

Image Credit: Anton Paar GmbH

Litesizer DIF's Quick-Click technology attaches the dispersion unit with a singular motion, eliminating complications involving connectors, tubing, or conduits. In addition, the opacity measurement display permits observation of specimen quantity during introduction, guaranteeing appropriate proportioning from initial application.

The dispersion units incorporate protective design elements. The Dry Jet dispersion mechanism features a vacuum verification and an integrated protective enclosure to mitigate powder dispersal hazards. Additionally, the Liquid Flow dispersion mechanism performs automated verification of adequate liquid presence preceding sonication, circumventing thermal stress.

Particle Sizing in Any Environment

Image Credit: Anton Paar GmbH

Anton Paar's Litesizer DIF is designed to meet the demands of demanding industrial sectors. Construction incorporates superior-grade materials throughout, accompanied by a 10-year warranty on laser components. Durable steel casing safeguards precision optical components.

Litesizer DIF demonstrates resilience in challenging operational settings: Contaminant particles and powder cannot infiltrate the optical platform of the apparatus, and the apparatus interior maintains separation from potential mechanical disturbances originating from operational zones. These characteristics result in reduced maintenance expenditures and restoration expenses.

Sharper Results with Image-Enhanced Diffraction

Interchangeability of dispersion units among Anton Paar's Litesizer DIA and Litesizer DIF configurations minimizes capital requirements and laboratory footprint. All Litesizer configurations operate through a unified computing infrastructure that uses the Kalliope platform.

Specifications

Source: Anton Paar GmbH

|

Litesizer DIF 500 |

Litesizer DIF 300 |

Litesizer DIF 100 |

| Measurement principle |

Laser Diffraction (Mie and Fraunhofer scattering) |

| Measurement range |

0.01 μm - 3,500 μm |

0.1 μm - 2,500 μm |

0.1 μm - 1,000 μm |

| Size classes |

144 (user adjustable) |

114 (user adjustable) |

104 (user adjustable) |

| Accuracy * |

better than ± 0.5 % variation*** |

| Repeatability |

better than ± 0.5 % variation*** |

| Reproducibility** |

better than ± 1 % variation*** |

| Typical measurement duration |

< 10 sec |

| Data acquisition rate |

16 kHz |

| Light source 1 |

|

| Type |

Fiber-coupled laser diode |

| Optical arrangement |

Reverse Fourier setup |

| Wavelength |

830 nm, infrared |

| Laser power |

10 mW |

| Laser class |

Class 1 (IEC60825-1) |

| Light source 2 |

Litesizer DIF 500 |

- |

| Type |

Laser diode |

- |

| Optical arrangement |

Tilted relative to the IR laser |

- |

| Wavelength |

450 nm, blue |

- |

| Laser power |

25 mW |

- |

| Laser class |

Class 1 (IEC60825-1) |

- |

| Detectors |

|

| Type |

Log-spaced photo diode array and single diodes for side and back-scattering |

| Angular range |

0.01 ° - 170 ° |

0.01 ° - 155 ° |

|

| Focal length |

300 mm |

| Alignment |

Automatic |

| Instrument data |

|

| Instrument dimensions**** |

400 mm x 790 mm x 290 mm (H x W x D) |

| Instrument weight**** |

42.3 kg (93.2 lb) |

| Power supply |

100 V to 240 V ±10 %, 50/60 Hz |

Trademarks: Kalliope (EU: 012709391, UK: UK00912709391), Litesizer (EU: 011695491, UK: UK00911695491)

* Defined for a monomodal latex standard and accounting for the manufacturer's uncertainty of standard size.

** Defined for D50 of a polydisperse standard.

*** Sample and preparation dependent. Defined for liquid dispersion measurements.

**** Without PC and dispersion unit